Stencil mask and method of producing the same, semiconductor device produced using the stencil mask and method of producing the semiconductor device

a stencil mask and masking technology, which is applied in the direction of semiconductor/solid-state device details, instruments, photomechanical equipment, etc., can solve the problems of pattern having a shape which cannot be kept, distortion so great that it cannot be ignored, and the pattern getting more and more difficult to reproduce with ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

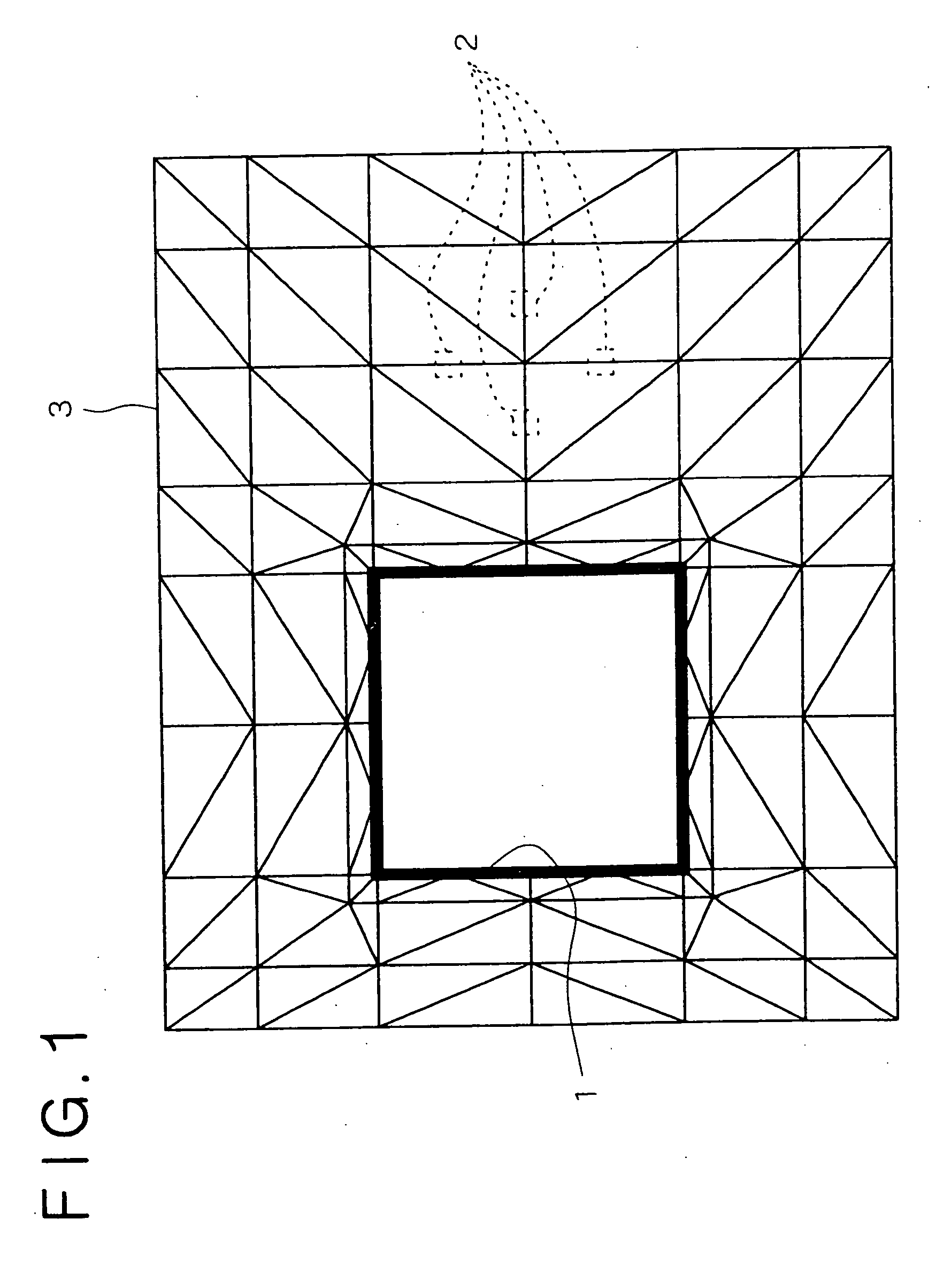

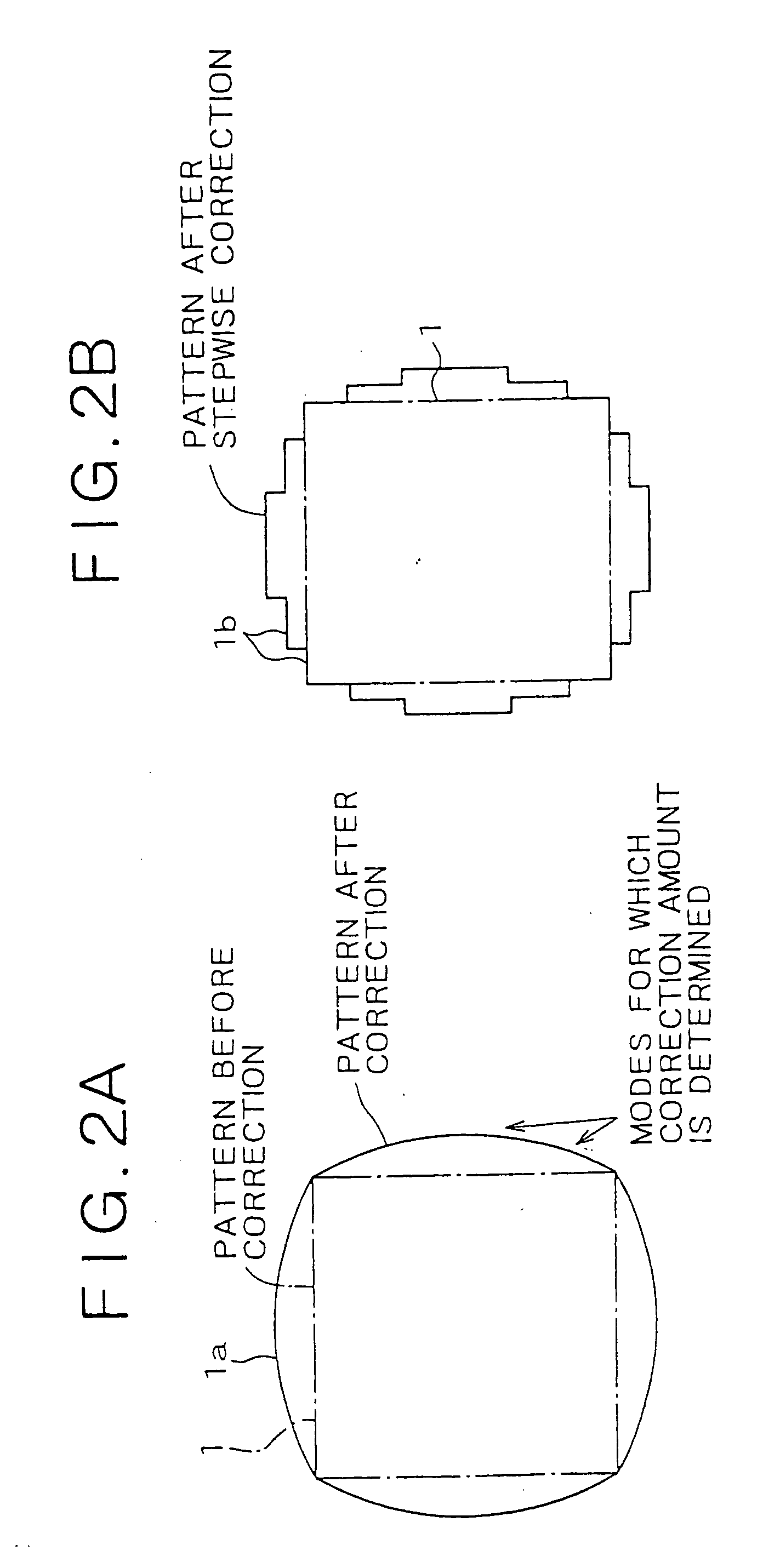

In the following, a method of producing a stencil mask to which the present invention is applied is described with reference to FIGS. 1, 2A and 2B.

Referring first to FIG. 1, a rectangular stencil mask pattern 3 having a single large stencil hole pattern 1 and four small stencil hole patterns 2 is shown. The stencil mask pattern 3 is divided into triangular elements except the large stencil hole pattern 1; and, only the single large stencil hole pattern 1 is assumed present, while the presence of the four small stencil hole patterns 2 is ignored.

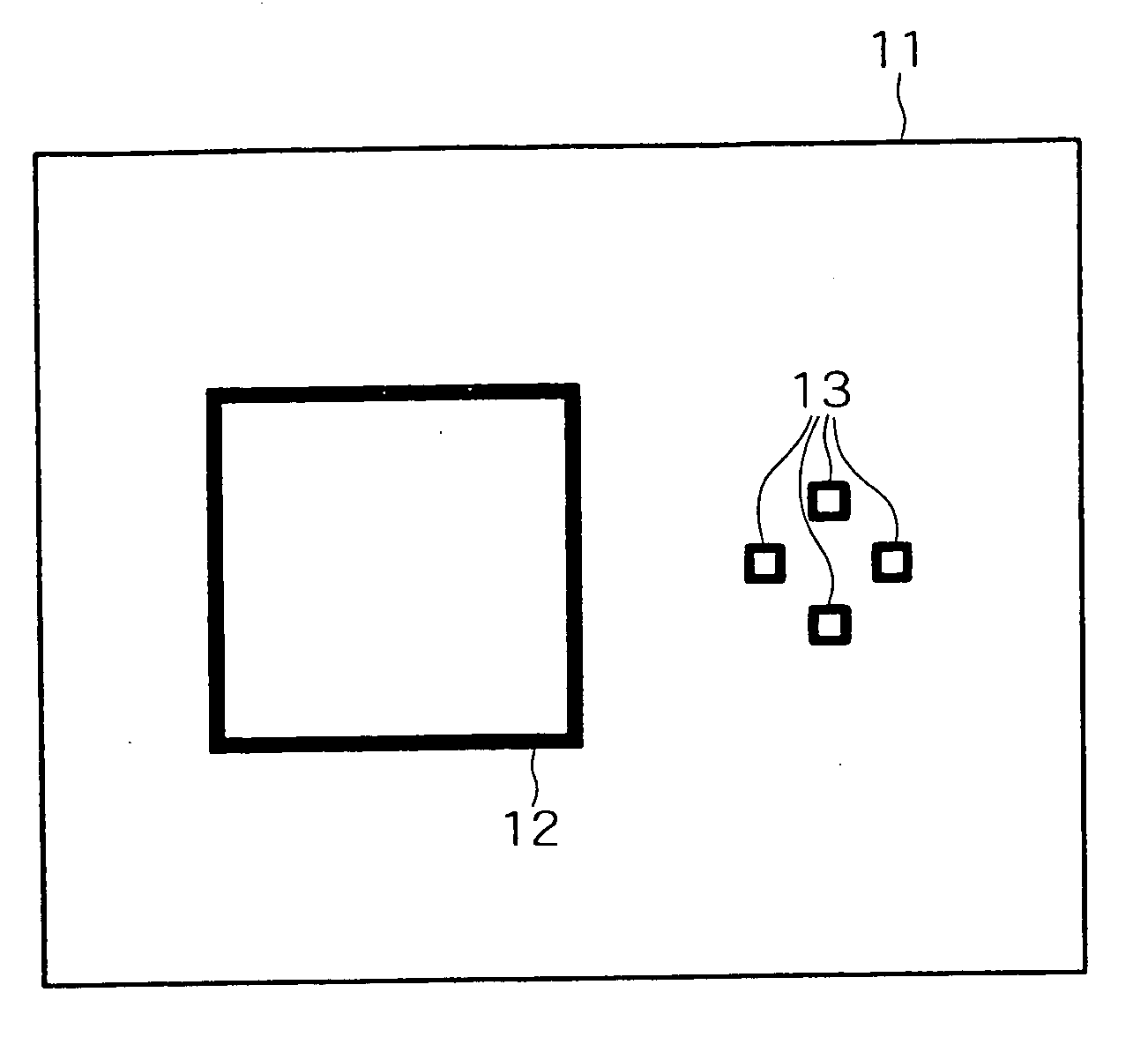

In the stencil mask pattern 3 shown, for example, the large stencil hole pattern 1 has a shape of a square having sides of 10 μm, and the small stencil hole patterns 2 have a shape of a square having sides of 100 nm. The numbers and the arrangement of the stencil hole patterns 1 and 2 are substantially the same as those of the stencil mask 11 of FIG. 3B.

Since, according to the stress analysis by the finite-element method, only a simple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| plane stress analysis | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com