Methods for dynamo-electric machine insulation handling

a technology of dynamo-electric machines and handling methods, which is applied in the field of methods for dynamo-electric machines insulation handling, can solve the problems of difficult lubrication and maintenance, impede the lubrication of internal mechanisms, and contamination of insulation materials, so as to increase the rate of insulation handling operations, increase the accuracy and reliability of cutting, forming and inserting operations, and increase the rate of shaft rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is now described in more detail in conjunction with FIGS. 1-6, which are provided to illustrate embodiments of the invention and not for limiting same.

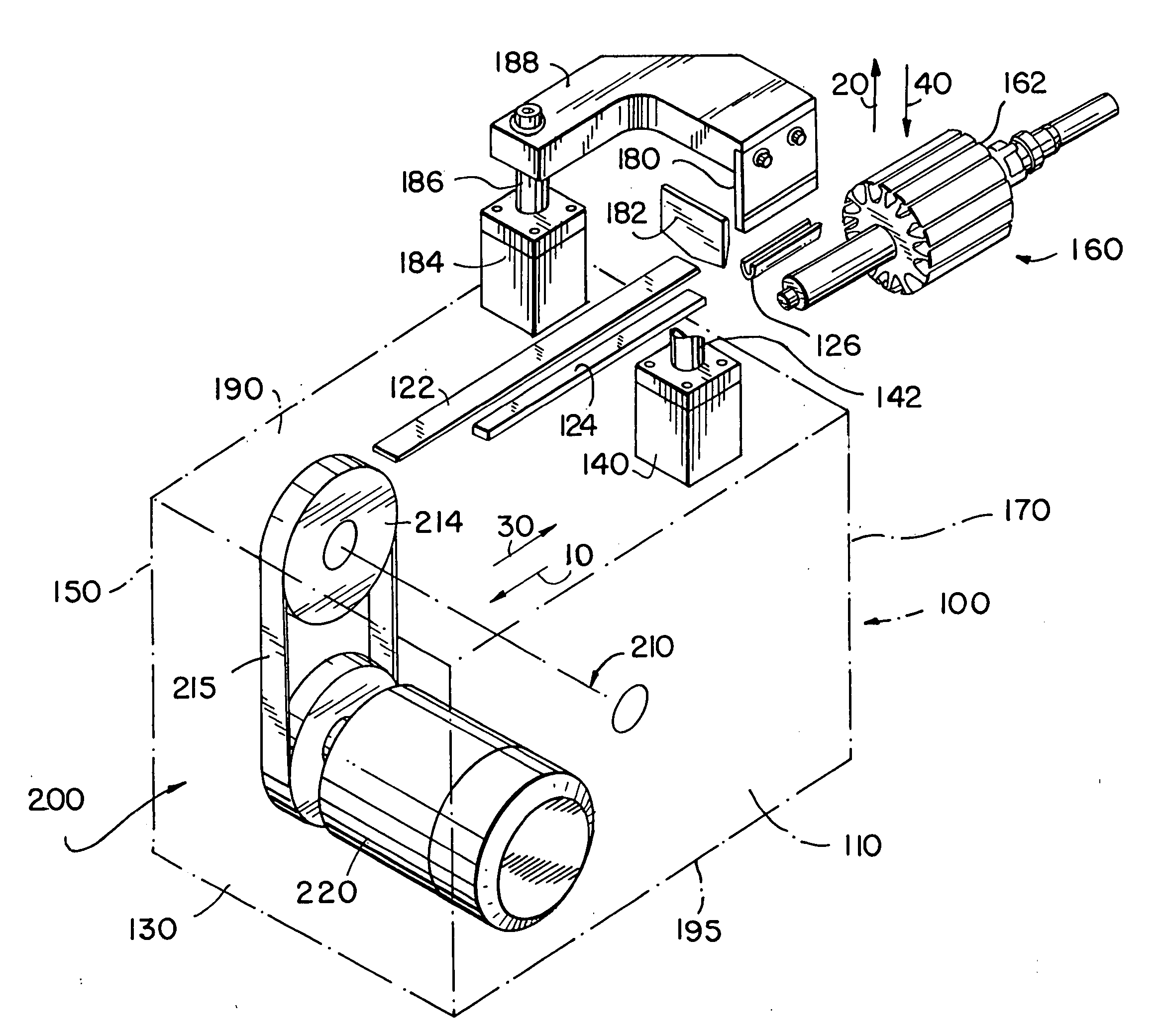

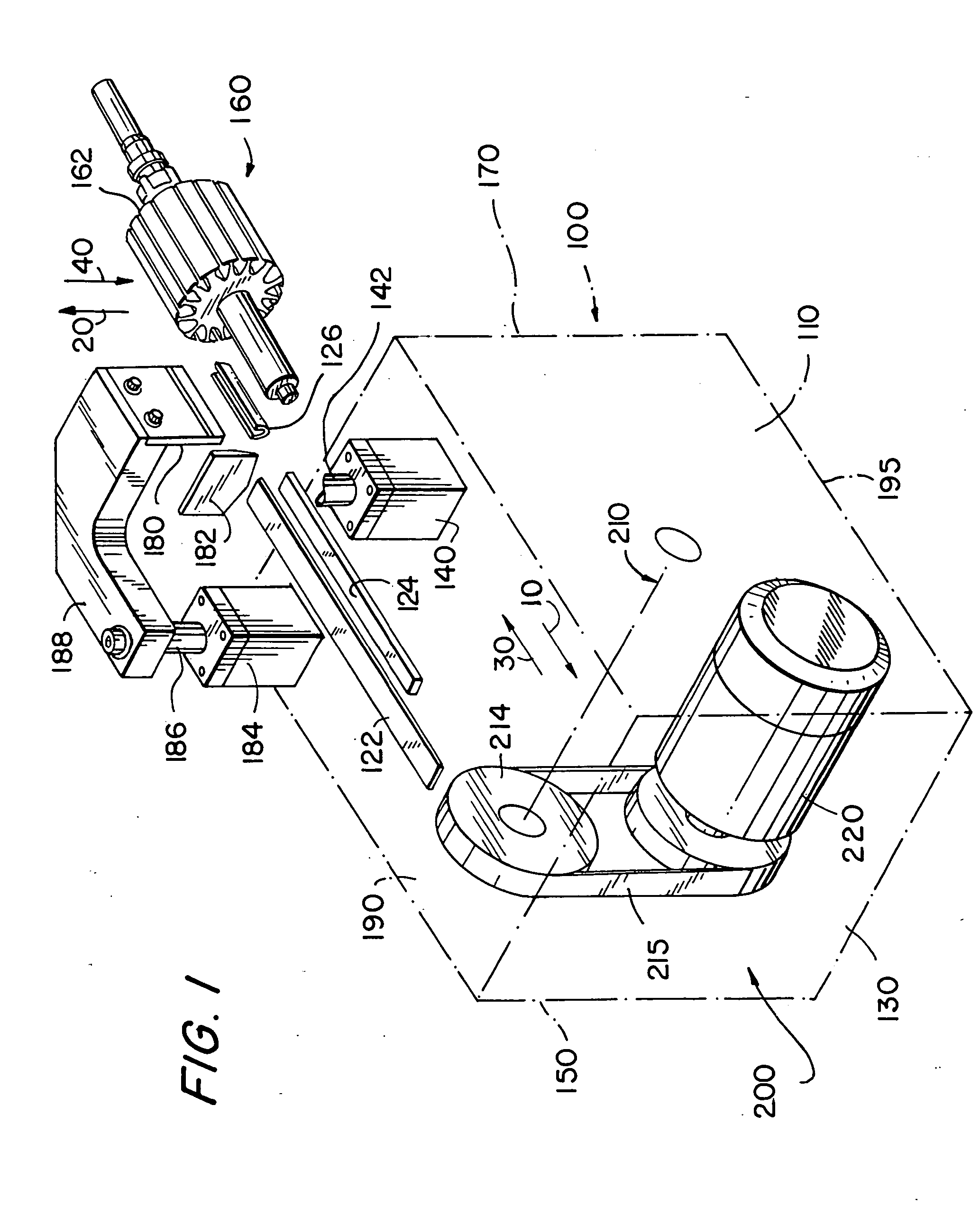

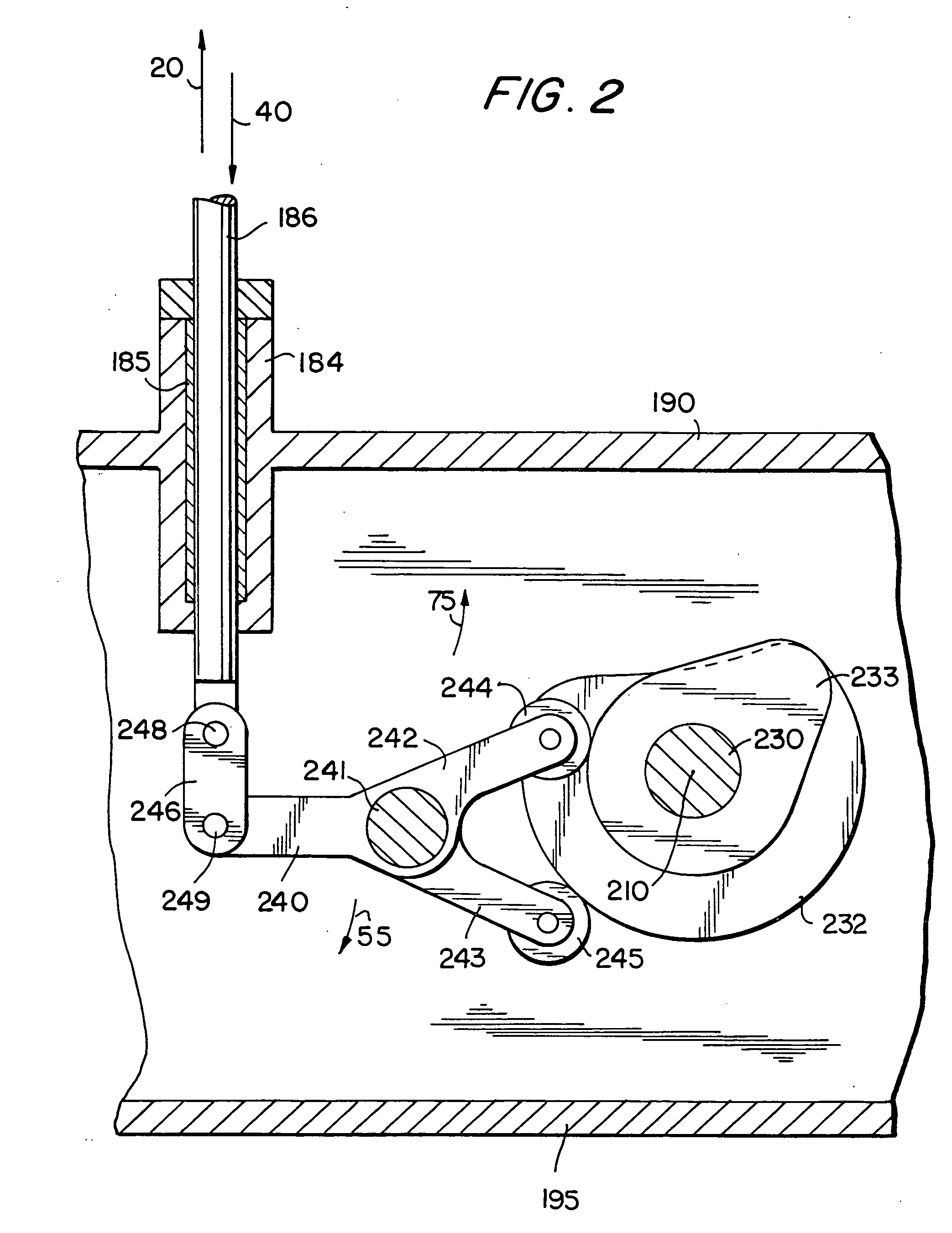

[0017]FIG. 1 depicts, in a perspective partial view, an illustrative insulating apparatus in accordance with various embodiments of the present invention. Certain parts (more fully identified in the following) are omitted for sake of clarity. Drive mechanism 200 may be used to drive the movement, at predetermined timing, of cutting member 182, forming member 180, and inserting member 124. Insert 126, which may be any suitable insulating material, is shown in FIG. 1 already formed and aligned with slot 162 of armature 160, where it may be inserted by inserting member 124.

[0018] During typical use of the apparatus shown in FIG. 1, inserting member 124 may preferably translate in horizontal forward direction 30 to push insert 126 into slot 162 of armature 160. Upon insertion of the insulation material, a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| insulating | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com