Protective suit ventilated by self-powered bellows

a technology of bellows and protective suits, which is applied in the direction of inhalators, ventilation protection, heat protection, etc., can solve the problems of avoiding the protection of suits, avoiding the protection high production costs of previously disclosed suits, so as to achieve the maximum area of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

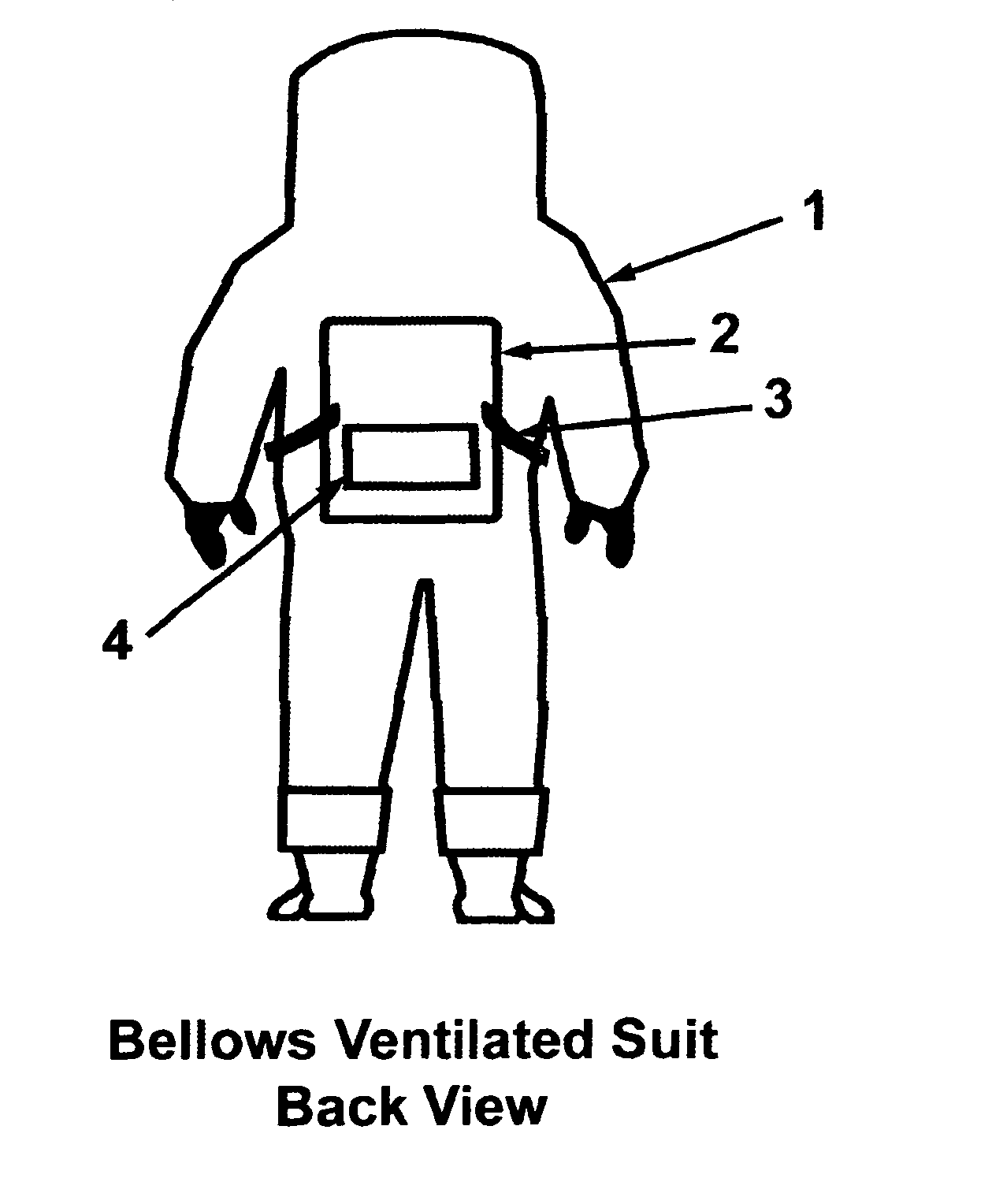

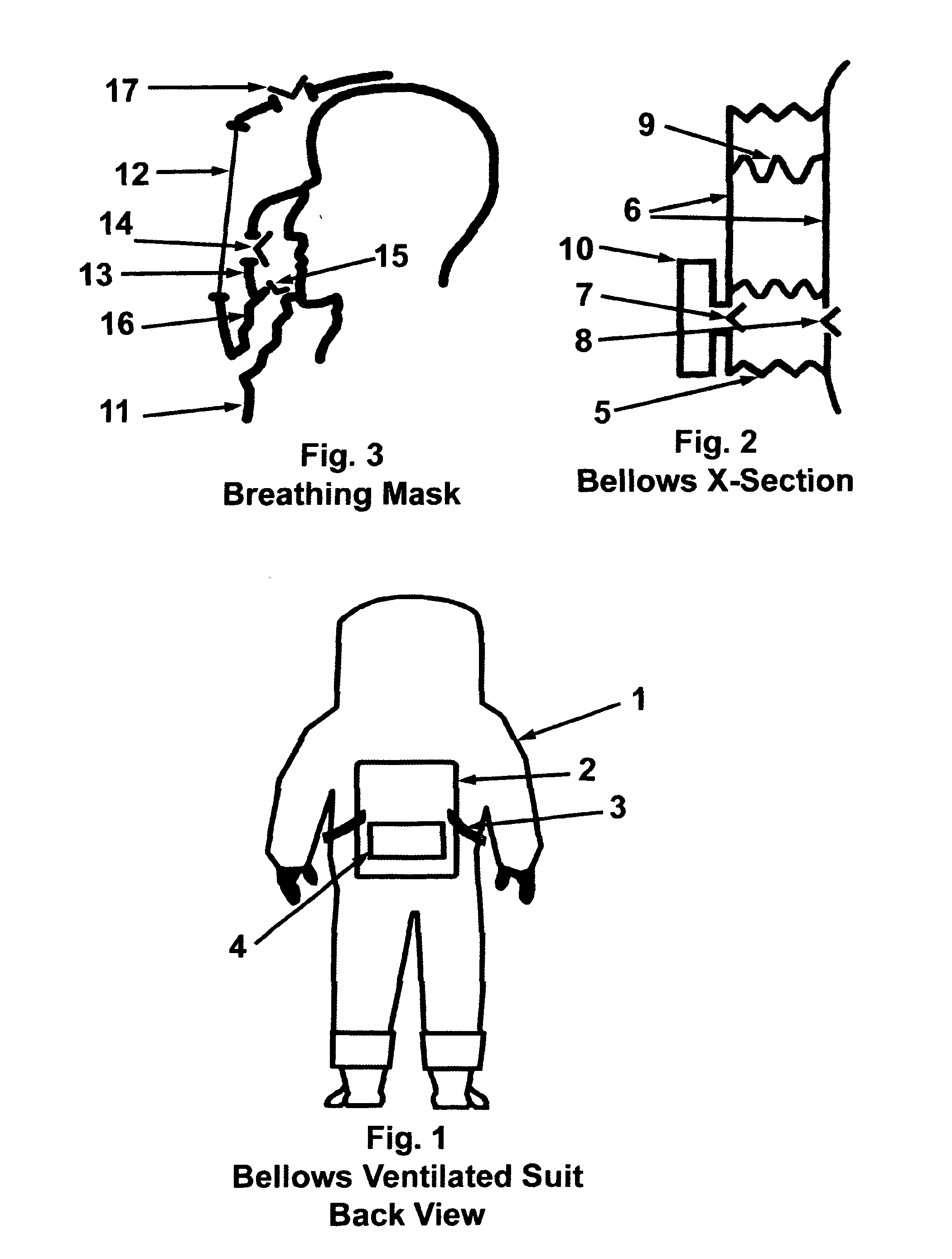

[0031]FIG. 1 is a rear view of the suit with the bellows attached to it's back. Item (1) is a protective suit. Item (2) is a bellows attached to the back of the suit. Items (3) are straps, attached to the bellows, which extend around the front of the suit. When the straps are pulled forward by the wearer, from the front of the suit, the bellows collapse, forcing air into the suit. When the straps are released, the bellows self-expands, drawing filtered air into the bellows. Item (4) is an air filter, attached to the bellows, which filters air entering the bellows.

[0032]FIG. 2 is a cross-sectional view of the Bellows. Item (5) is a flexible material forming the collapsible sides of the bellows. Items (6) are plates forming the front and back bases of the bellows. Item (7) is a one-way valve (also known as a check valve or automatic valve) which allows air to be drawn into the bellows when the bellows expands. Item (8) is a one-way valve which allows air to be forced into the suit's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com