Ladle

a technology of ladles and cylinders, applied in the field of ladles, can solve the problems of unavoidable air drawn, unsatisfactory product quality, and increased production costs, and achieve the effect of significant improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

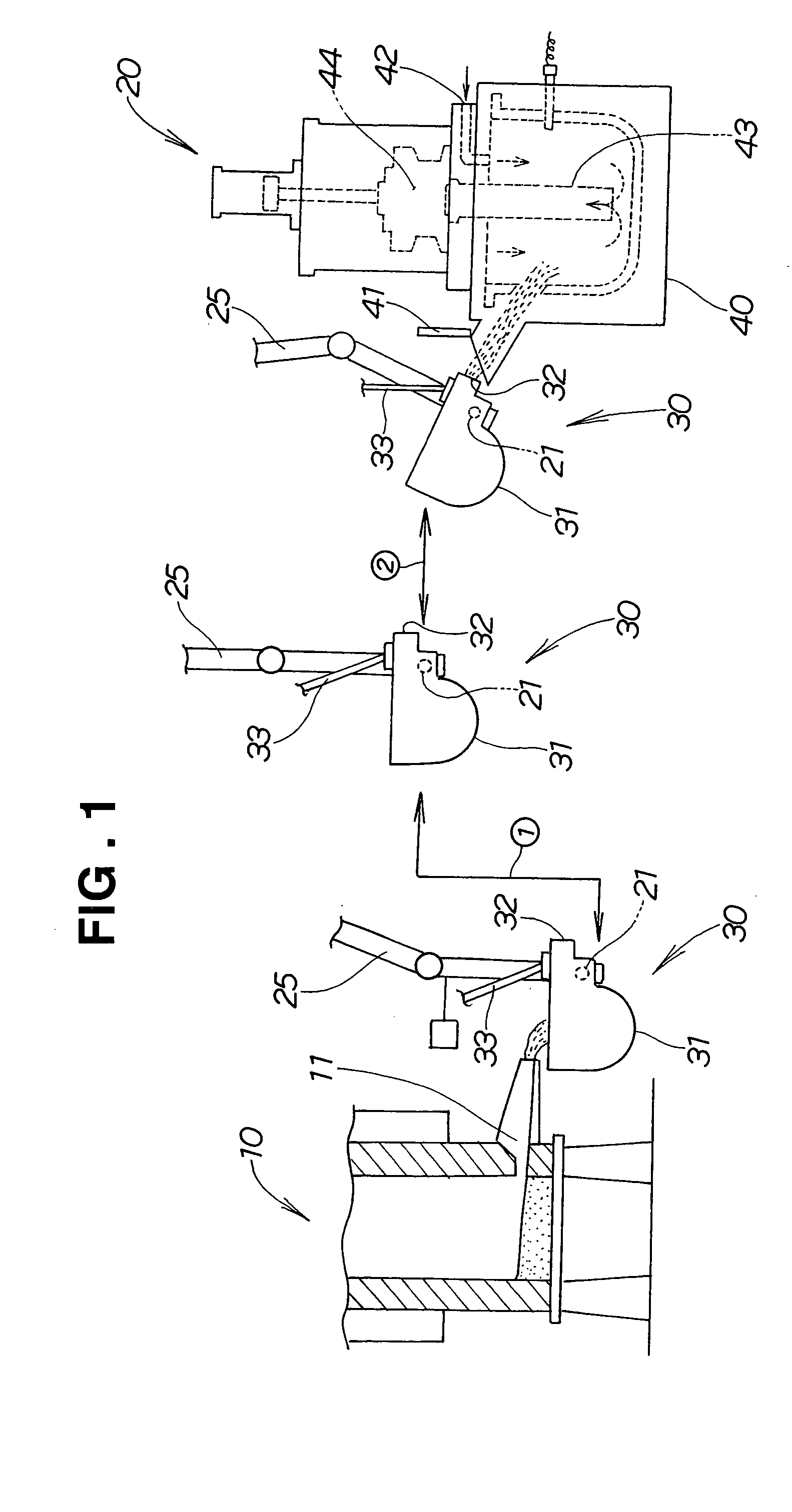

[0018] Example manner in which a ladle of the present invention is used will be explained first, prior to a detailed description about structural features of the ladle.

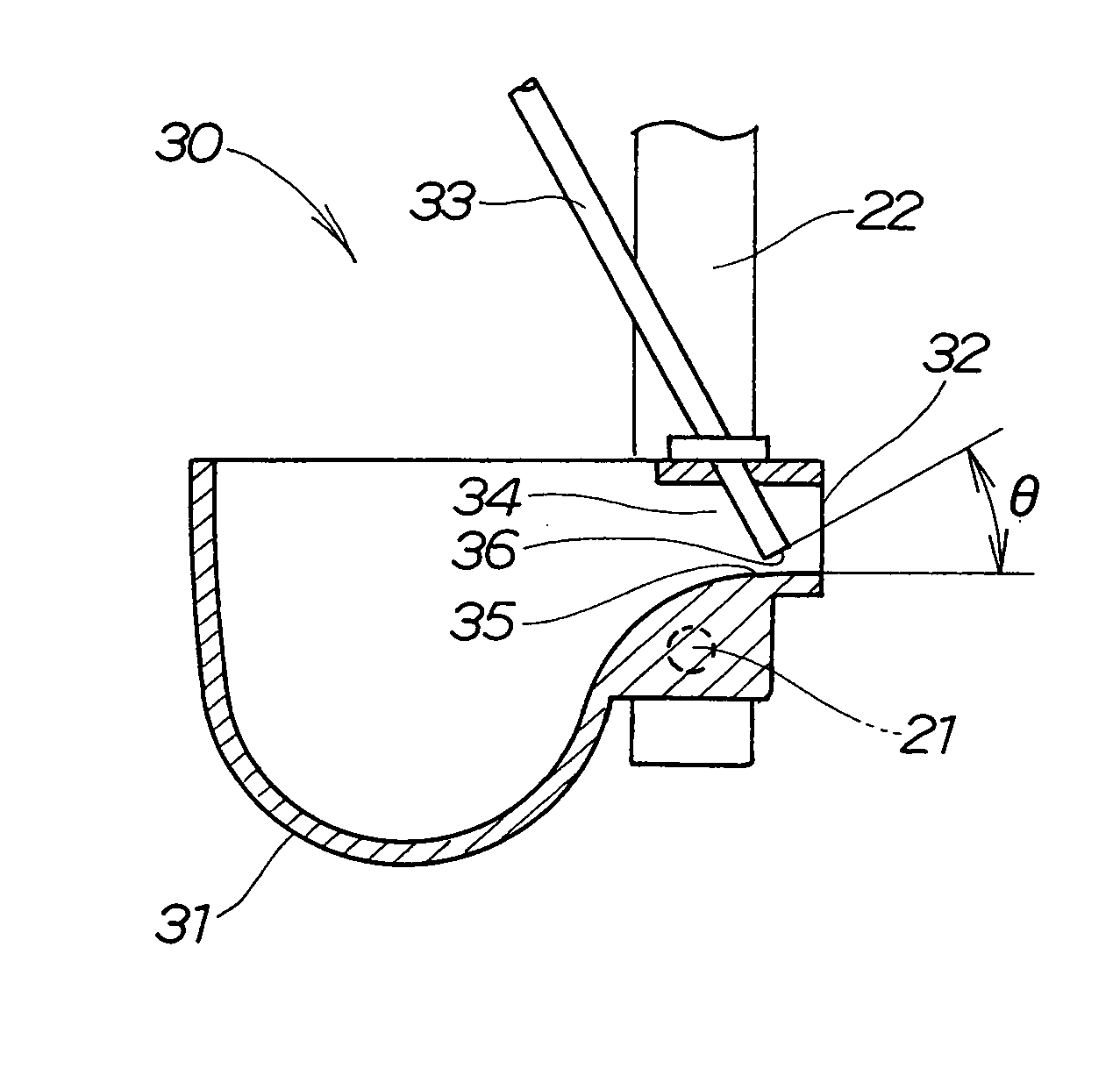

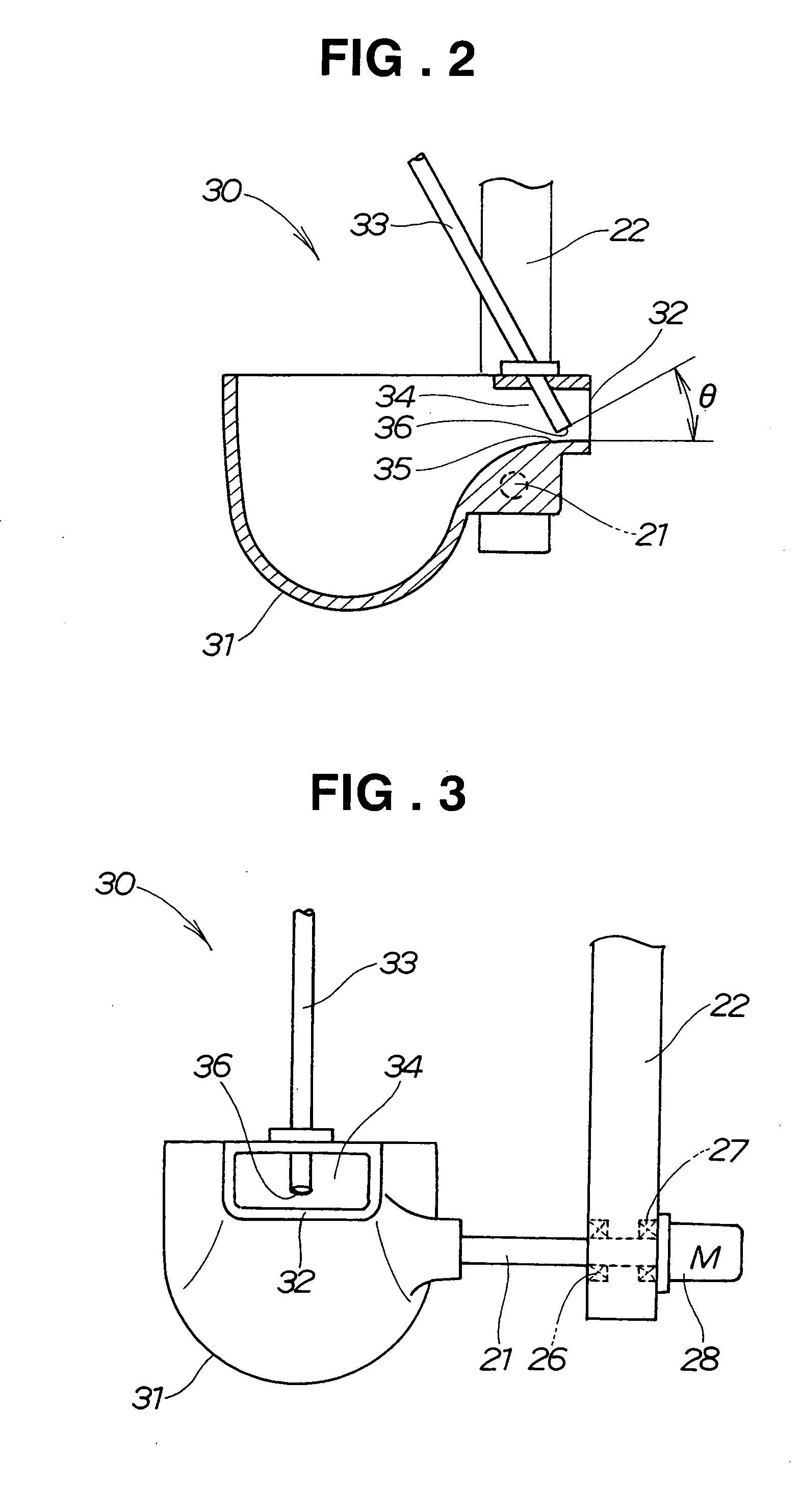

[0019]FIG. 1 is a view illustrating the example use of the ladle of the present invention. Generally, the ladle 30 is required because a casting machine 20 is installed a certain appropriate distance from an aluminum melting furnace 10. Namely, the ladle 30 is initially positioned to front a tapping hole 11 of the aluminum melting furnace 10 in proximity thereto, so as to receive molten material (in this case, molten aluminum) from the tapping hole 11. The ladle 30 is movable as depicted by arrow {circle over (1)} and arrow {circle over (2)}, through operation of a robot arm 25, so as to front a molten material holding furnace 40 in proximity thereto; the holding furnace 40 is attached to the casting machine 20.

[0020] When molten material is to be poured from the ladle 30 into the molten material holding furnace 40,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com