Patterned platelets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

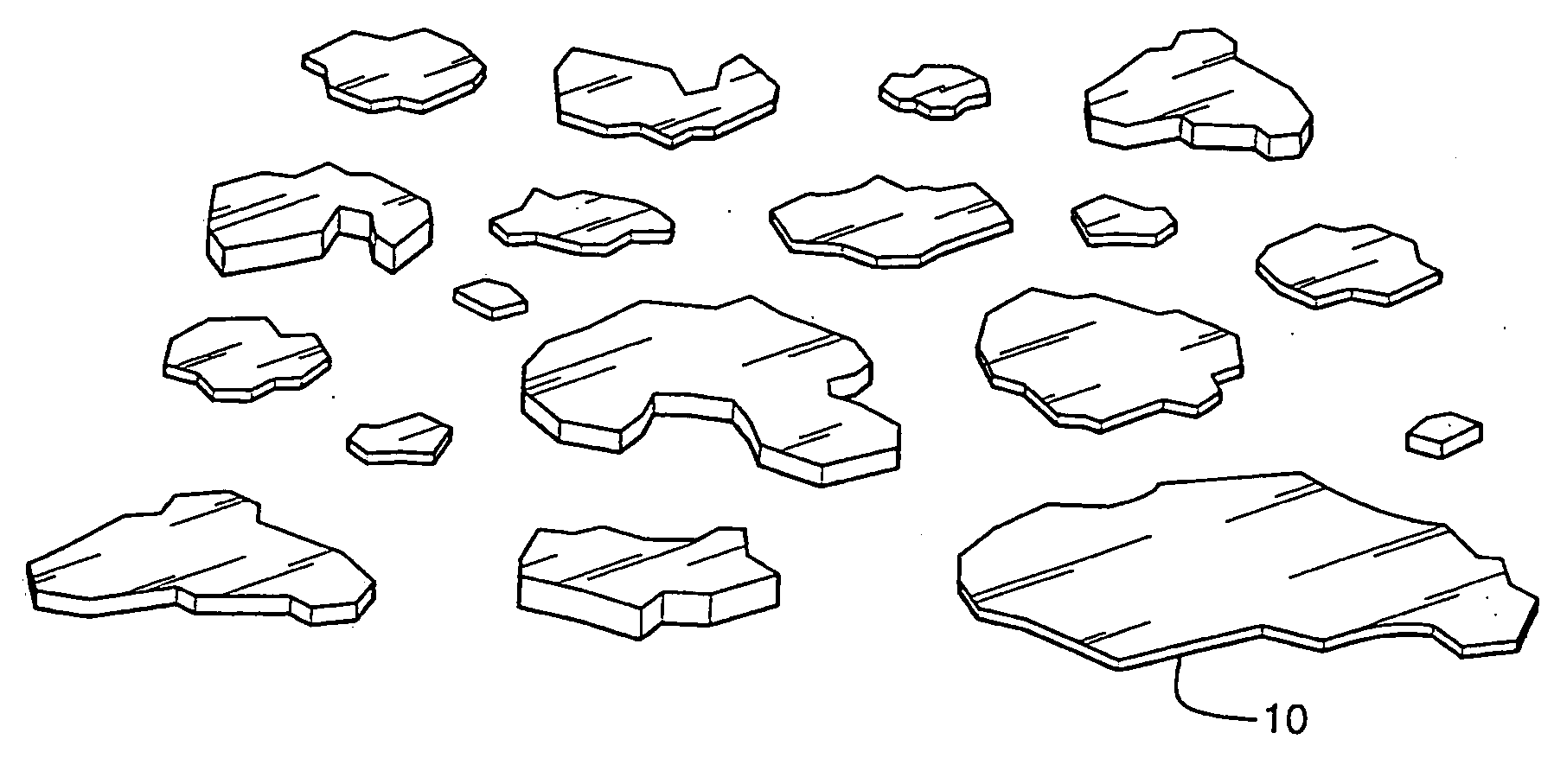

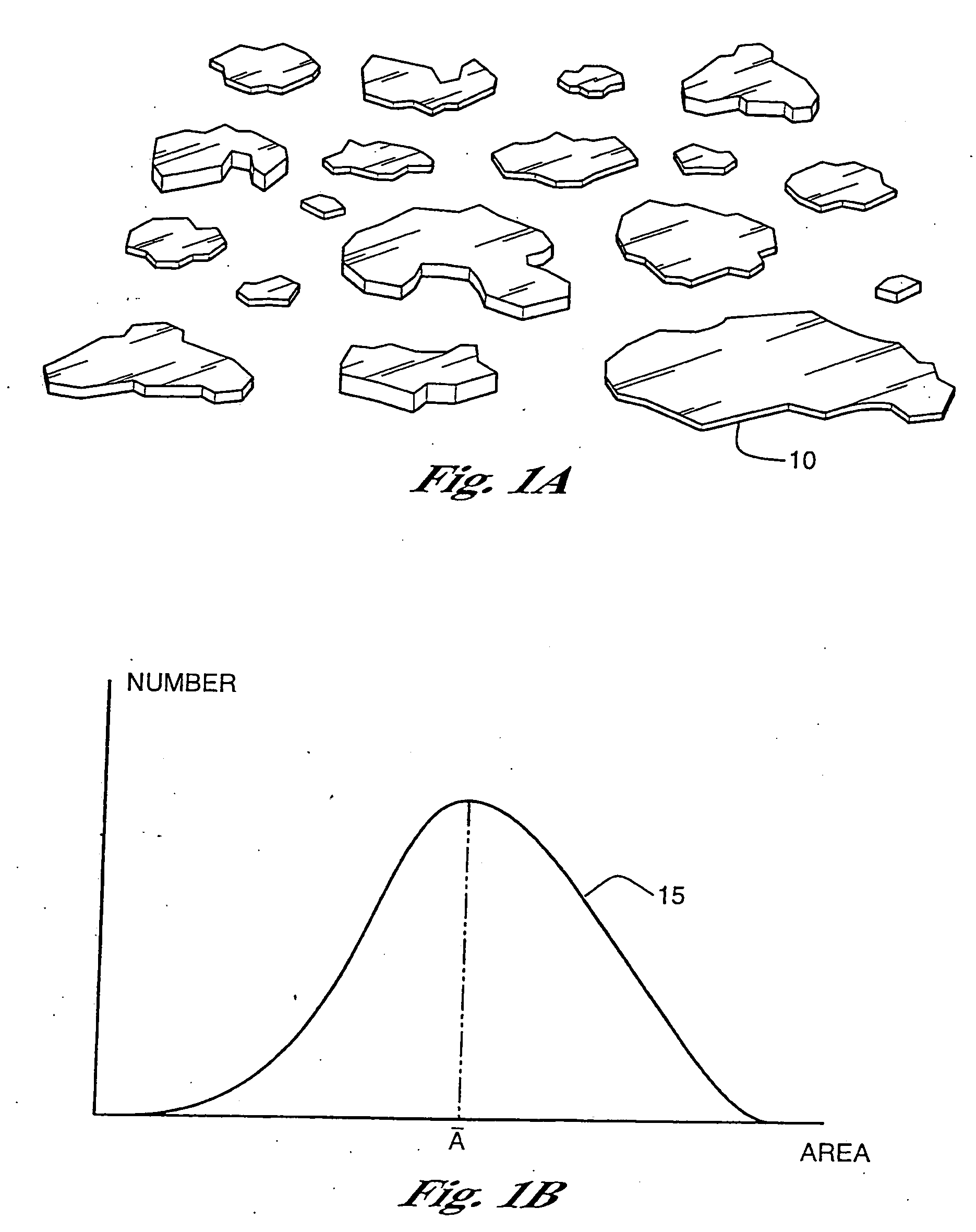

The prior art, such as in U.S. Pat. Nos. 5,415,950, 5,500,313 and 5,362,315, teach methods of producing platelet pigments 10 which have random sizes and random shapes as illustrated in FIG. 1A. These platelets 10 are made by making color producing thin films coated on large substrates. These color films are then removed from their substrates and broken into smaller fragments. Several milling steps are used to produce yet smaller fragments, flakes or platelets having thickness ranging from about 1 micron to about 20 micron and lateral dimensions ranging from about 3 microns to about 1,000 microns. Platelets are defined as flat structures with lateral dimensions at least a factor 2 larger than the average thickness, preferably more than 5 times larger than the average thickness. This ensures that when the platelets are applied to a substrate they will lay flat. As defined herein, patterned platelets, as used in this invention, are on the order of about 1 micron to about 1000 microns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com