Metal loaded carbon filaments

a technology of carbon filaments and metals, applied in the field of metal-loaded carbon filaments, can solve the problems of high cost, low temperature, uneconomical development, etc., and achieve the effect of increasing the number of applications of conventional carbon filaments, and increasing the cost of carbon filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

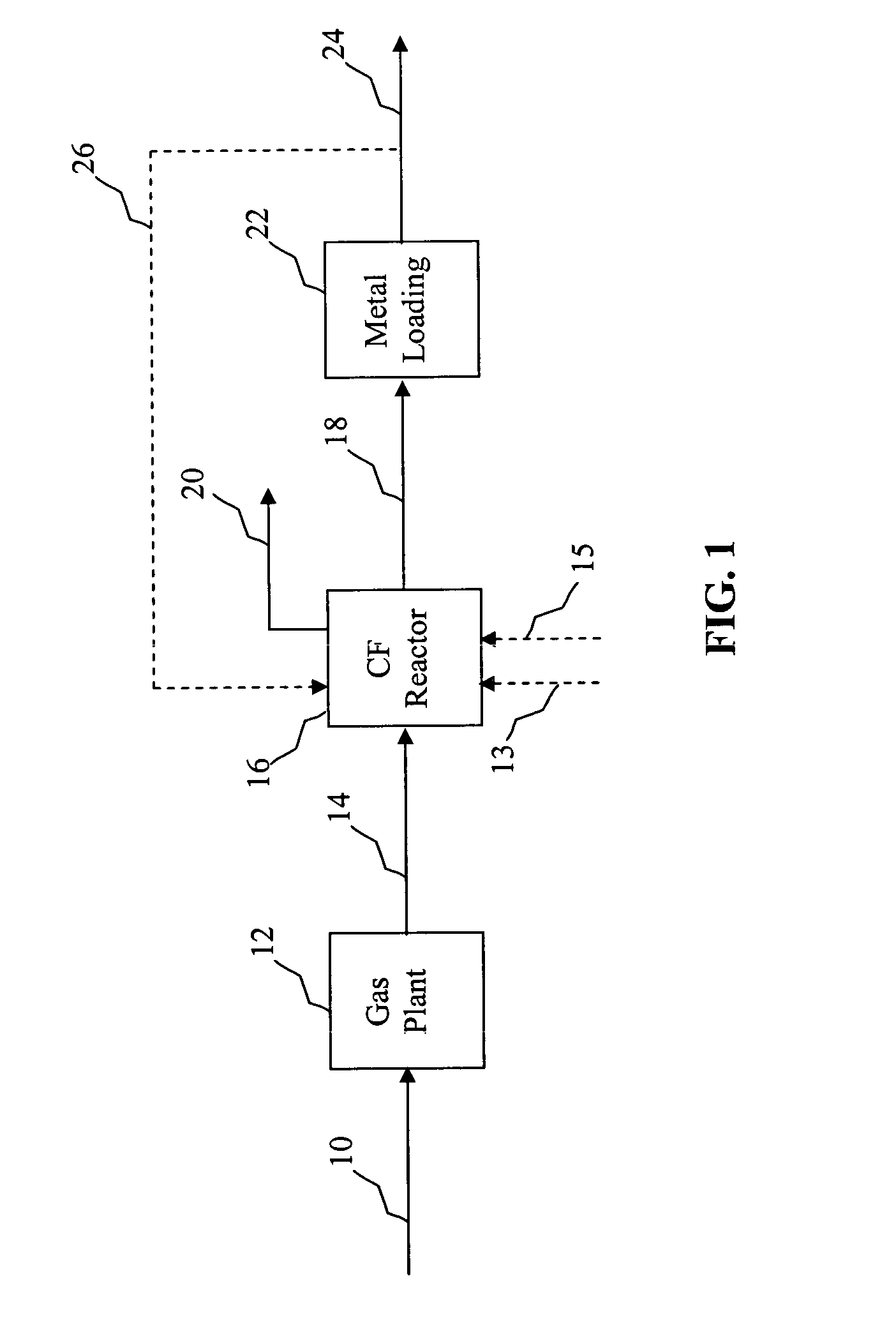

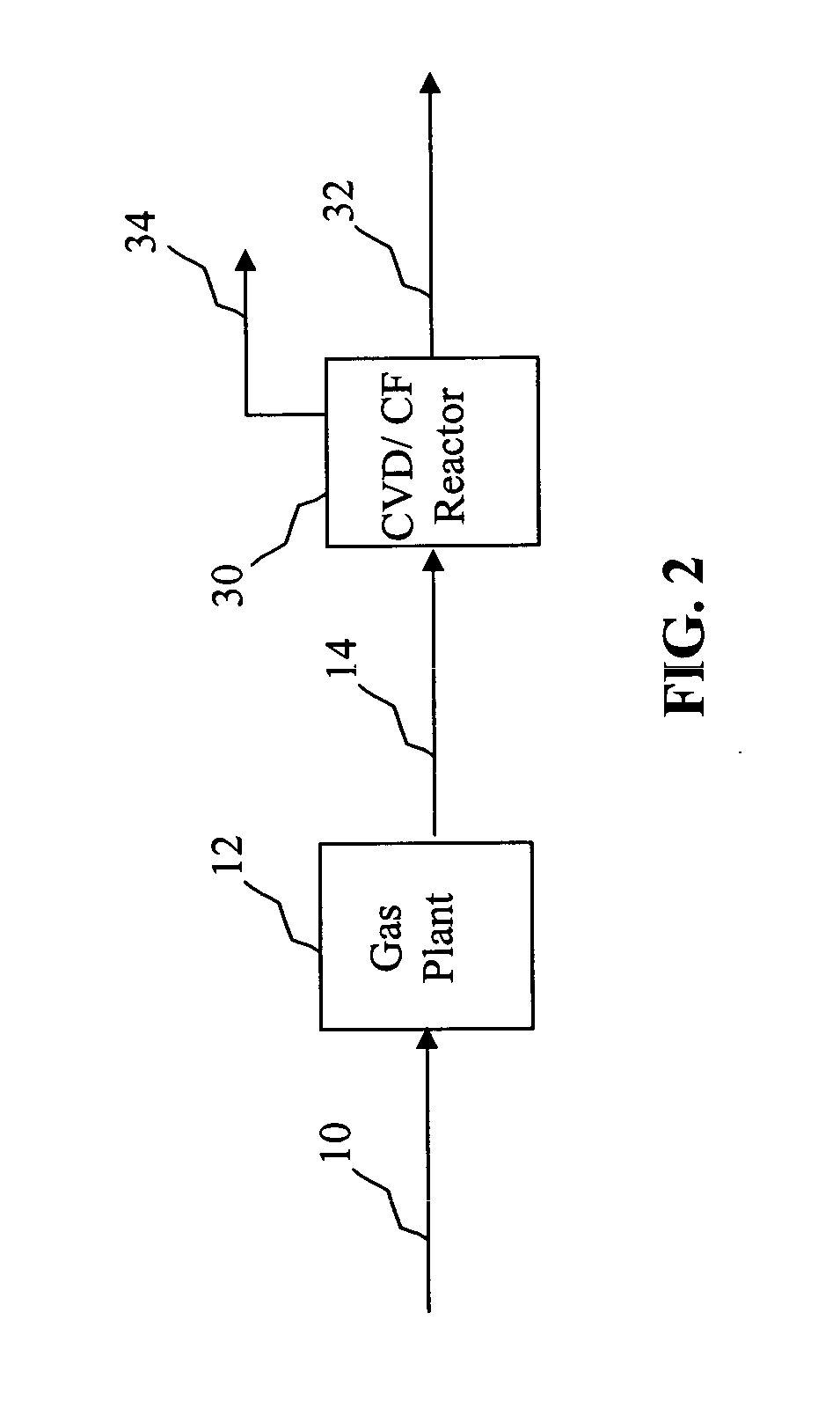

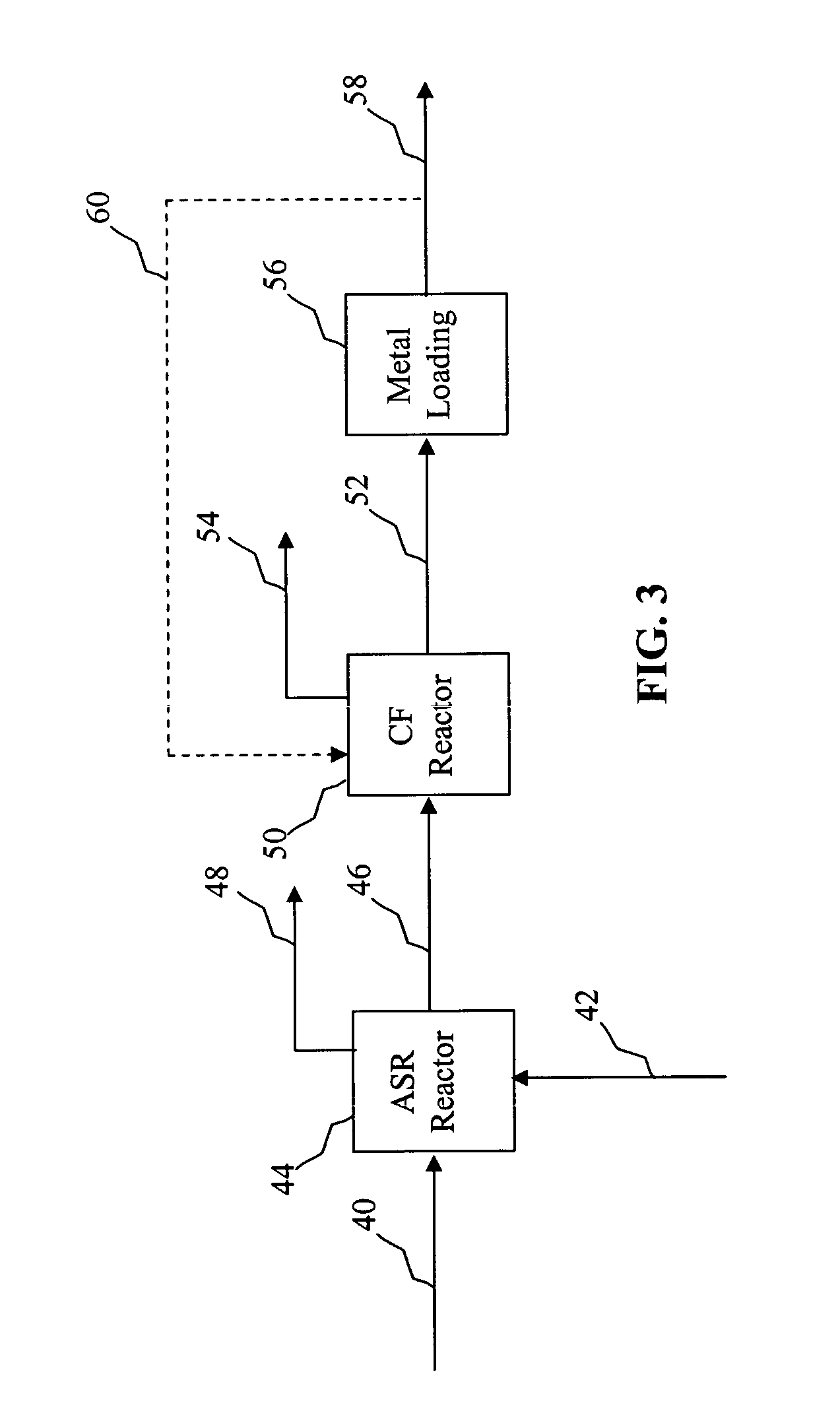

Method used

Image

Examples

examples

[0042] The invention having been generally described, the following example is given as particular embodiments of the invention and to demonstrate the practice and advantages thereof. It is understood that the examples are given by way of illustration and are not intended to limit the specification or the claims to follow in any manner.

[0043] Carbon filaments were prepared using a tube furnace with a quartz reactor tube containing a Monel screen (1″W×6″L). First, the tube furnace was heated to 650° C. under N2 flow at 200 mL / min. Once the temperature reached 650° C., ethylene flowing at 200 mL / min and N2 flowing at 60 mL / min were fed to the furnace, and the exit gases were analyzed using a gas chromatograph (GC) containing a thermal conductivity detector (TCD) for hydrocarbon products. The reaction was continued at 650° C. for a time period ranging from 1 hour to 4 hours, with 2 hours being the standard run length. After this time, the gas flows were stopped, and the reactor was al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com