Flip-chip interconnect with increased current-carrying capability

a chip and current-carrying technology, applied in the field of circuit devices, can solve the problems of “electrically open” solder joints, general unsolderability and corrosion of aluminum and its alloys, and achieve the effect of improving the current-carrying capability of solder bump connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

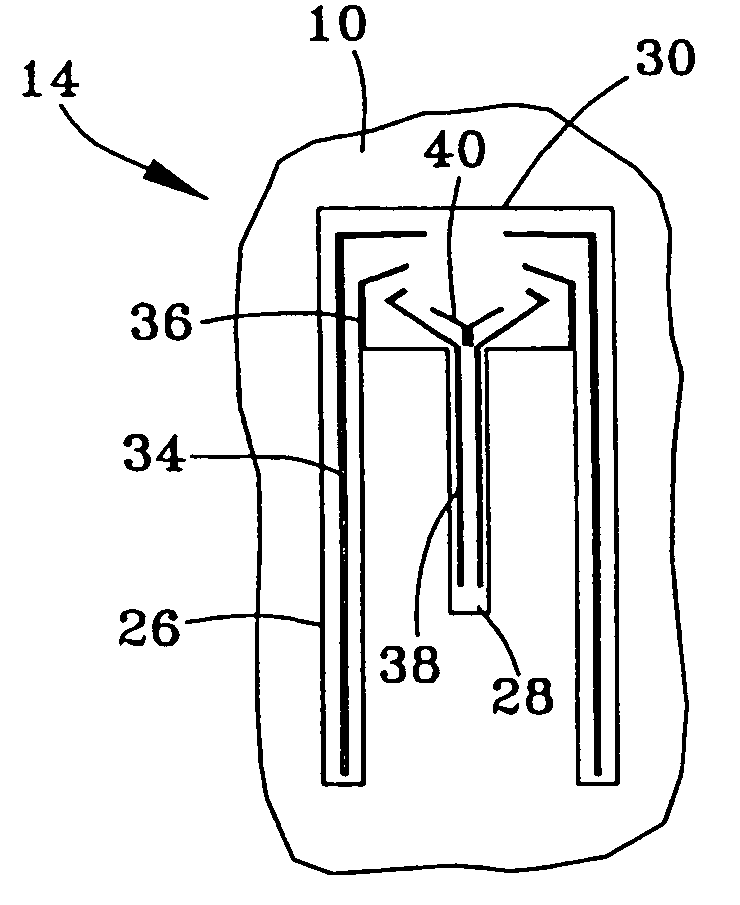

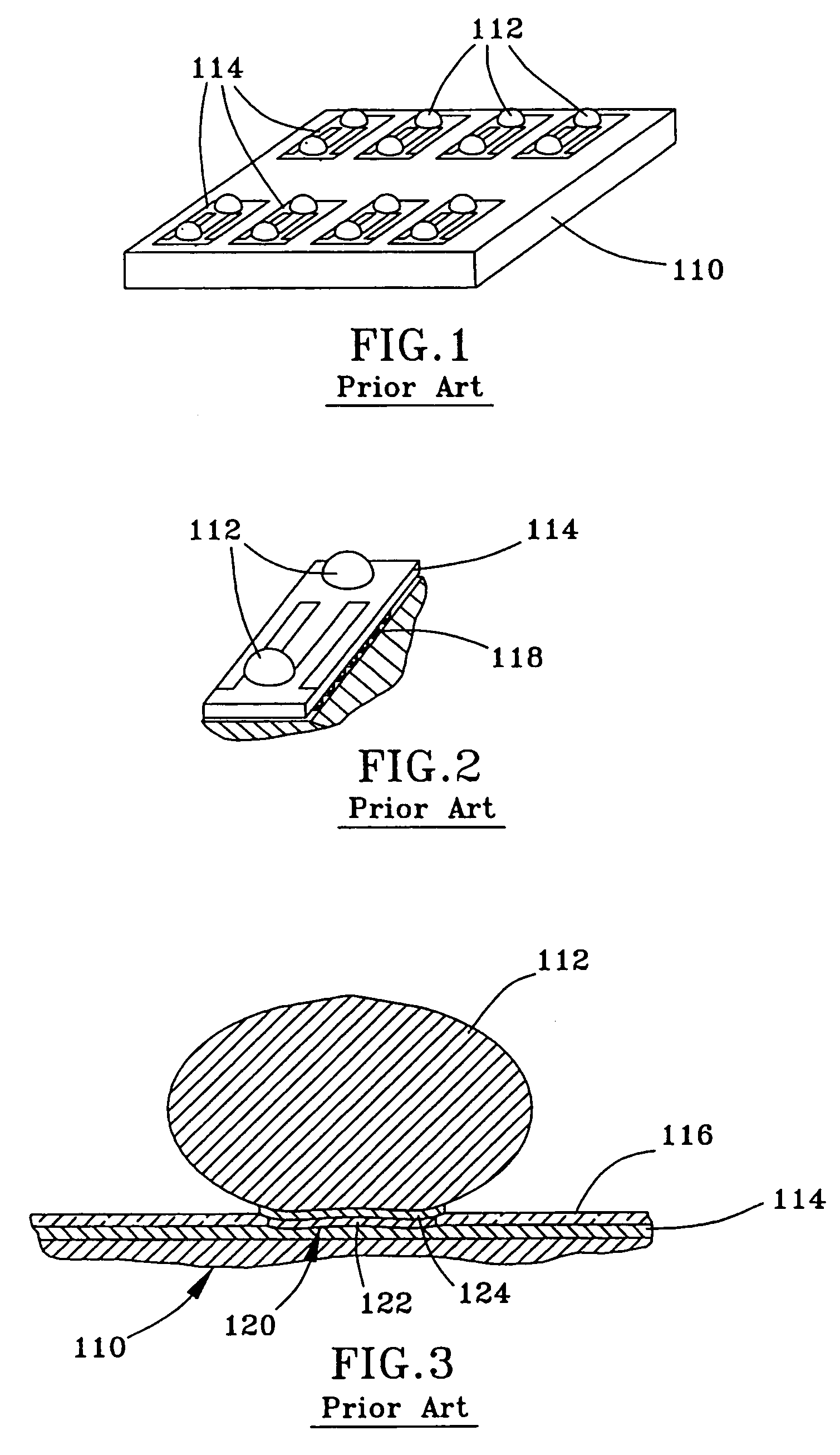

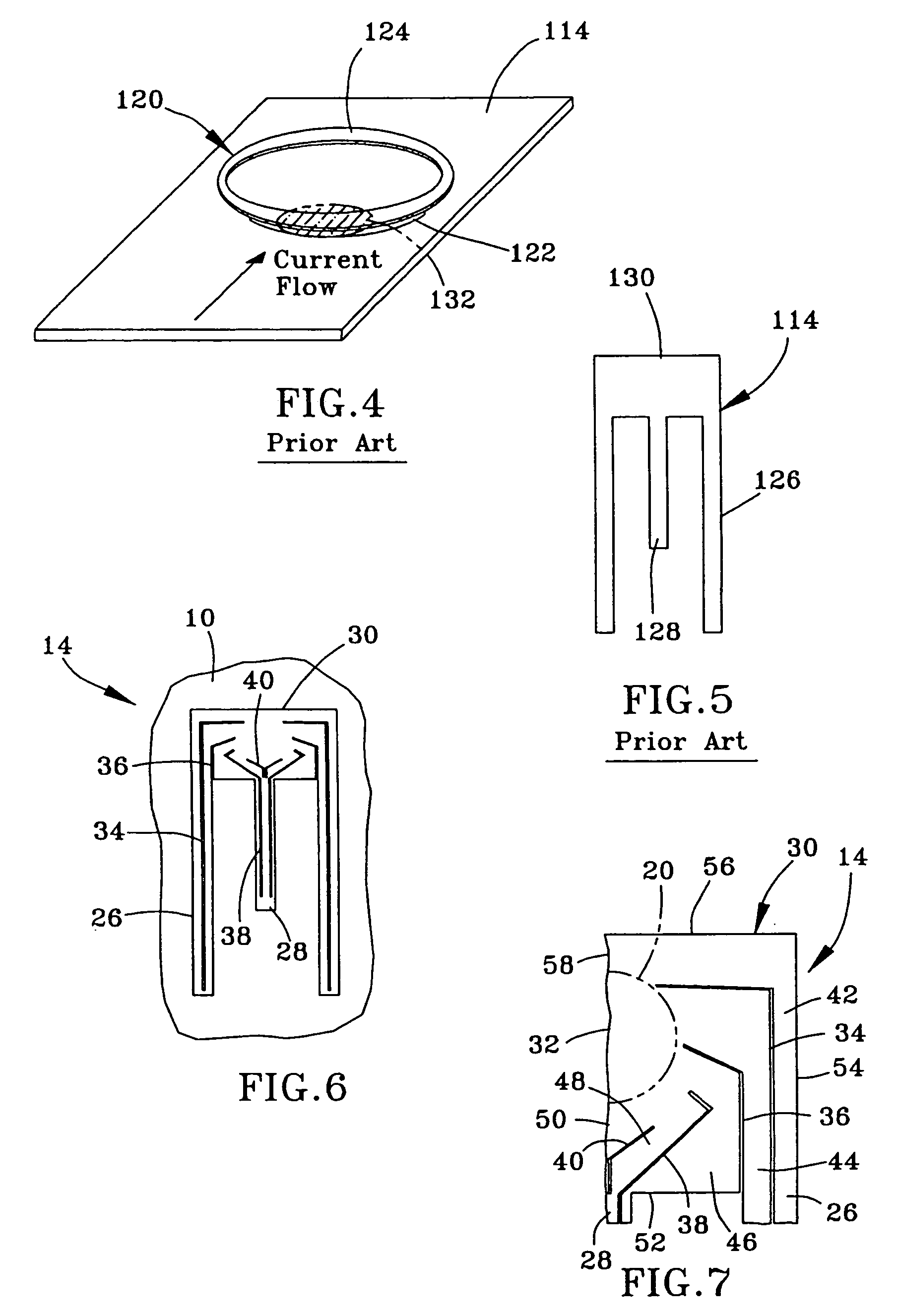

[0021] The present invention is directed to improving the reliability of surface-mount devices, such as flip chips of the type represented in FIGS. 1 through 3. According to one aspect of the present invention, current density within a solder bump (e.g., 112 in FIGS. 1 through 3) significantly contributes to electromigration, and therefore controlling current density can be effective in minimizing and preventing open solder connections caused by electromigration. Current density in a structure is defined as current flow per unit area (in a plane perpendicular to the direction of current flow) at various points in a structure, and is a good indicator of least resistant paths for electrical current flow through the structure.

[0022] In an investigation leading to this invention, it was observed that portions of a solder bump that have considerably higher current density than the bulk of the solder bump are more prone to electromigration. A solder bump inherently poses some level of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com