High electron mobility transistor with multiple channels

a high electron mobility, transistor technology, applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of controllability issues or lattice damage problems, depleting the 2deg underneath the gate region, and slowed down the electrons, so as to achieve enhanced current carrying capability, high electron mobility transistors, and preservation of current carrying capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

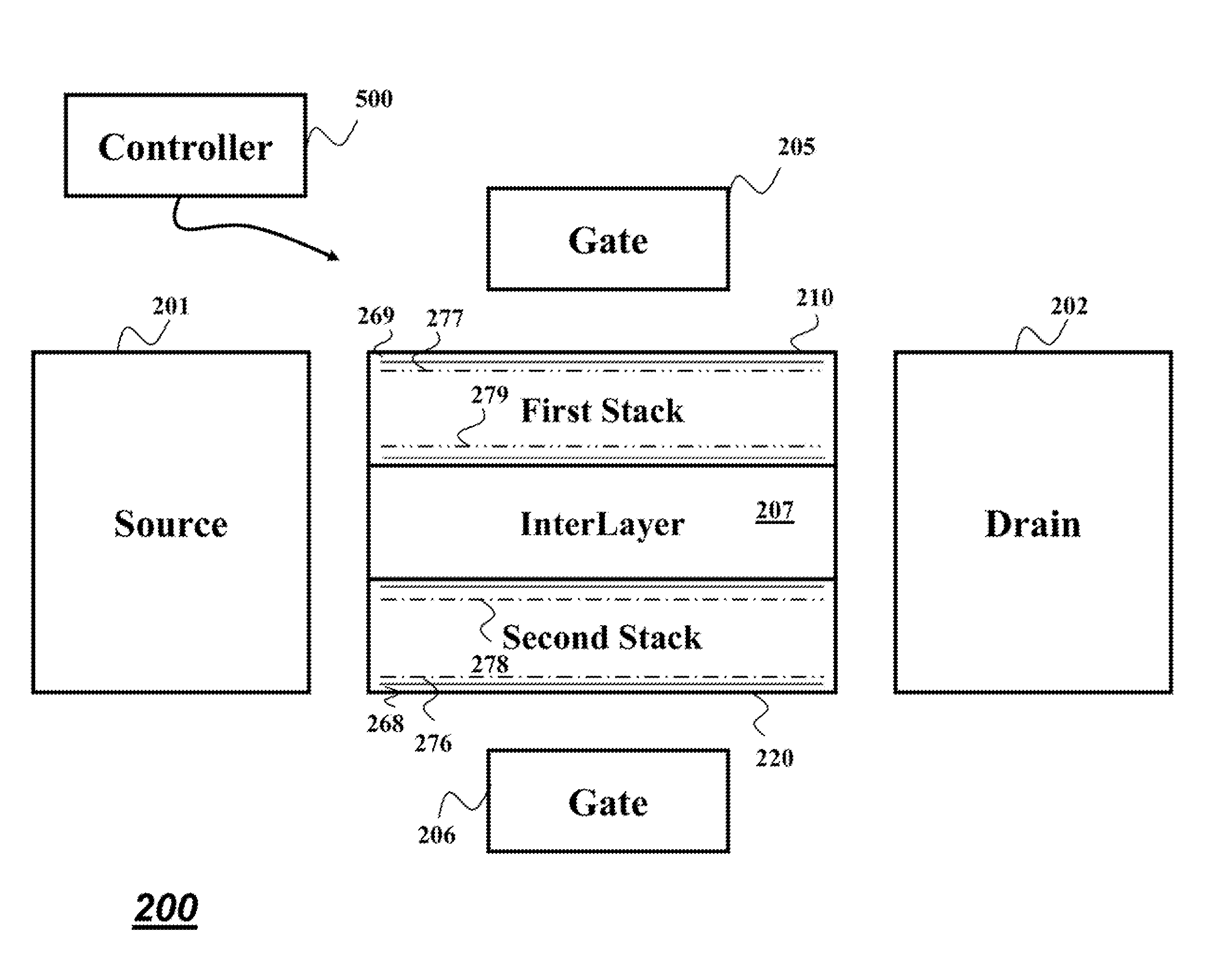

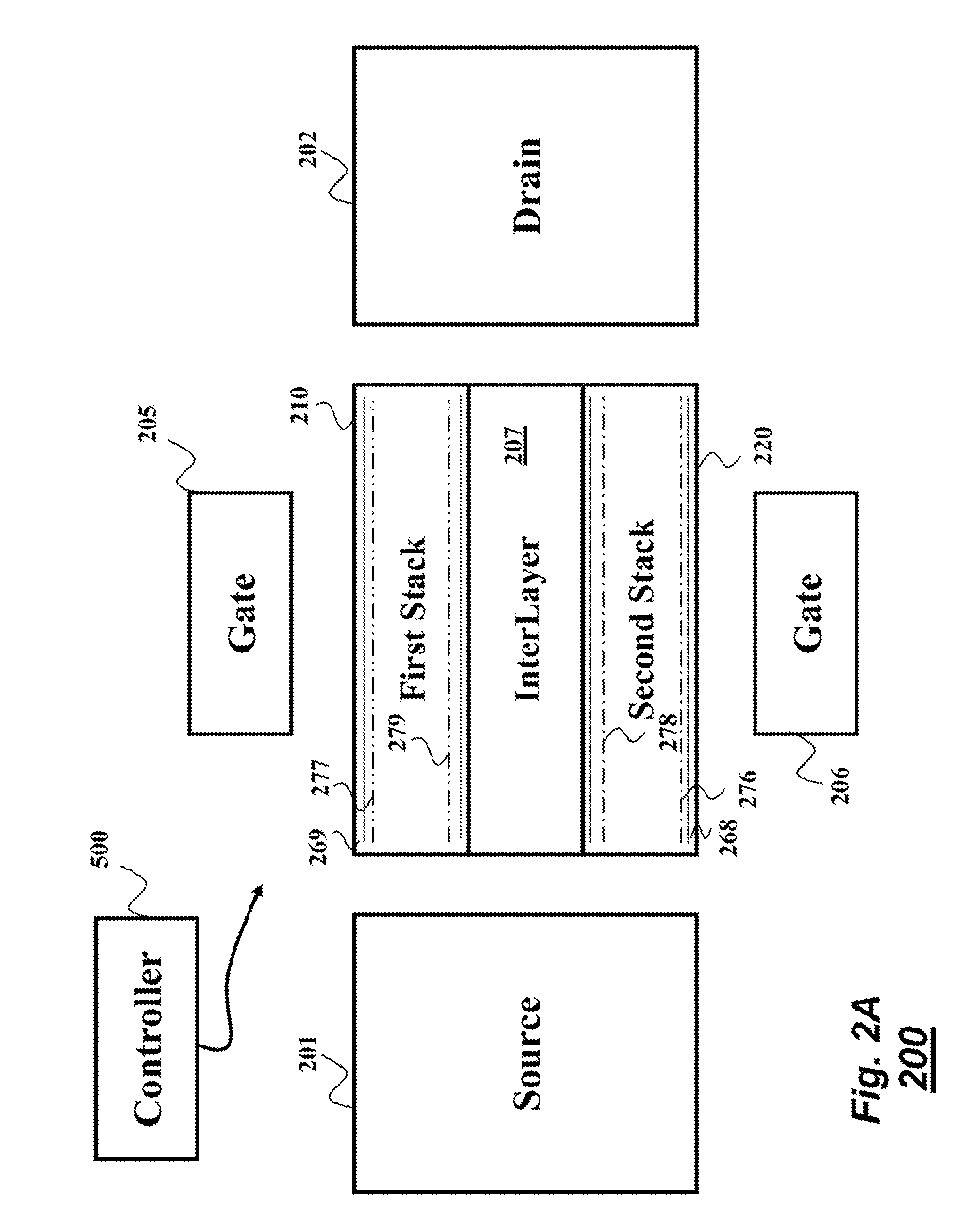

[0044]FIG. 2A shows a schematic of a device 200 designed according to some embodiments of the invention. The device can be a high electron mobility transistor (HEMT) including a source 201 for transmitting electronic carriers, and a drain 202 for receiving electronic carriers. The device also includes two stacks of different polarity for providing at least part of a conduction path between the source and the drain, i.e., a first stack 210 and a second stack 220. The device can also include a interlayer 207 deposited between the first and the second stacks, and at least one gate 205 operatively connected to at least the first stack for controlling a conduction of the electronic charge.

[0045]In various embodiments, the first and the second stack are heterostructures including a gallium nitride (GaN) layer for generating two-dimensional electron gas (2DEG) channels due to polarization difference at heterojunction. For example, the gate 205 controls the conduction of the electronic char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com