Electro-kinetic air transporter and conditioner devices with insulated driver electrodes

a technology of electric motor and driver electrode, which is applied in the direction of electrostatic charge, chemical/physical/physical-chemical process, energy-based chemical/physical/physical-chemical process, etc., can solve the problem of reducing the collecting efficiency of the system, the extent of voltage difference can be increased is limited, and the inability to achieve excessive quantities, etc. problem, to achieve the effect of increasing the particle collection efficiency, increasing the rate and/or volume of airflow, and reducing arcing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

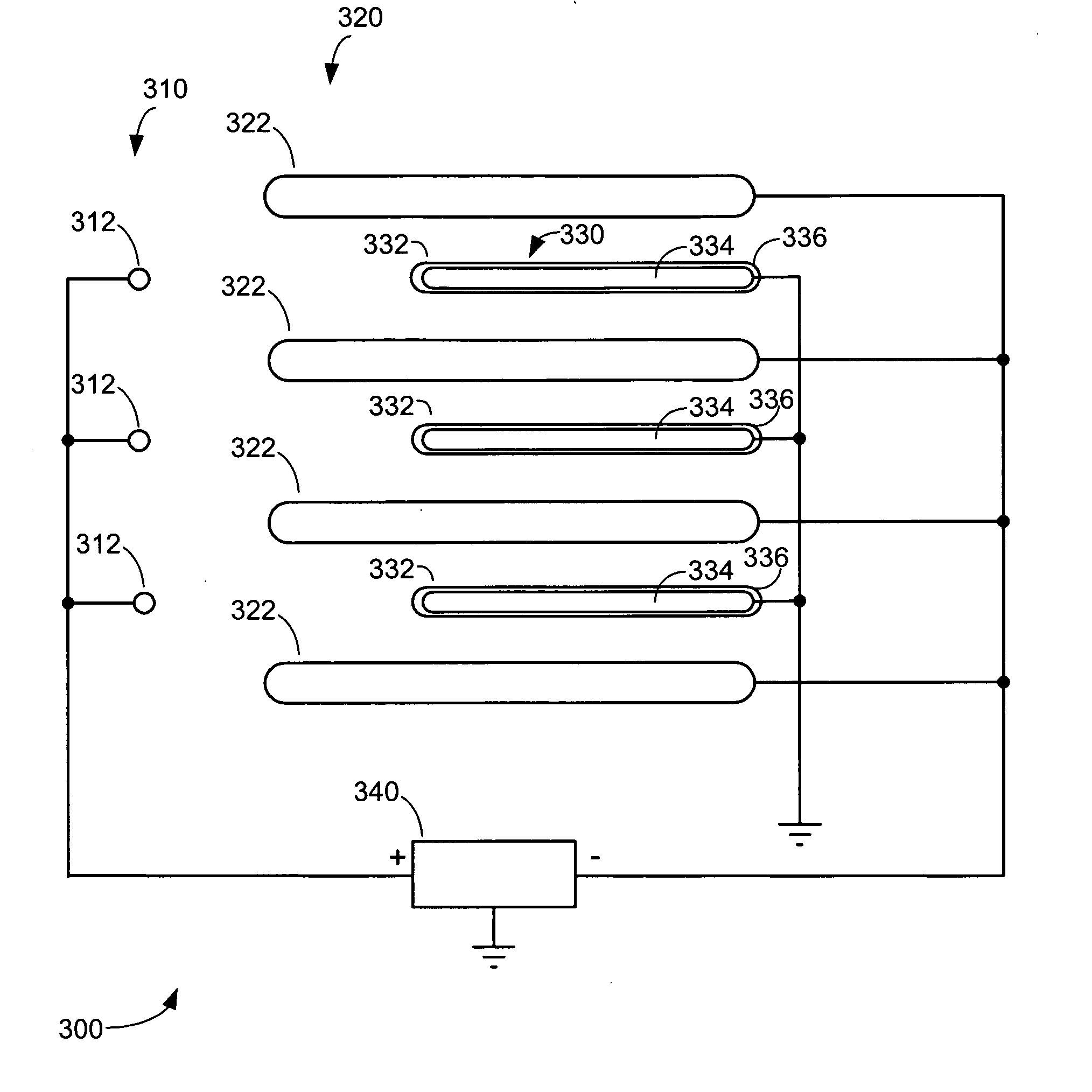

[0035]FIG. 3 illustrates schematically, an electro-kinetic conditioner system 300 according to an embodiment of the present invention. The system includes a first array 310 (i.e., emitter array) of emitter electrodes 312, a second array 320 (i.e. collector array) of collector electrodes 322 and a third array 330 of insulated driver electrodes 330. In this embodiment, the first array 310 is shown as being connected to a positive terminal of a high voltage source 340, and the second array 320 is shown as being connected to a negative terminal of the high voltage source 340. The third array 330 of insulated driver electrodes 332 are shown as being grounded.

[0036] Each insulated driver electrode 332 includes an electrically conductive electrode 334 that is covered by a dielectric material 336. In accordance with an embodiment of the present invention, the dielectric material 336 is heat shrink tubing. During manufacture, the heat shrink tubing is placed over the driver electrodes 334 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com