Low part count blower-motor assembly in common housing

a blower motor and common housing technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of high part count of these assemblies, high noise generation, and relatively inefficient assembly and manufacturing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

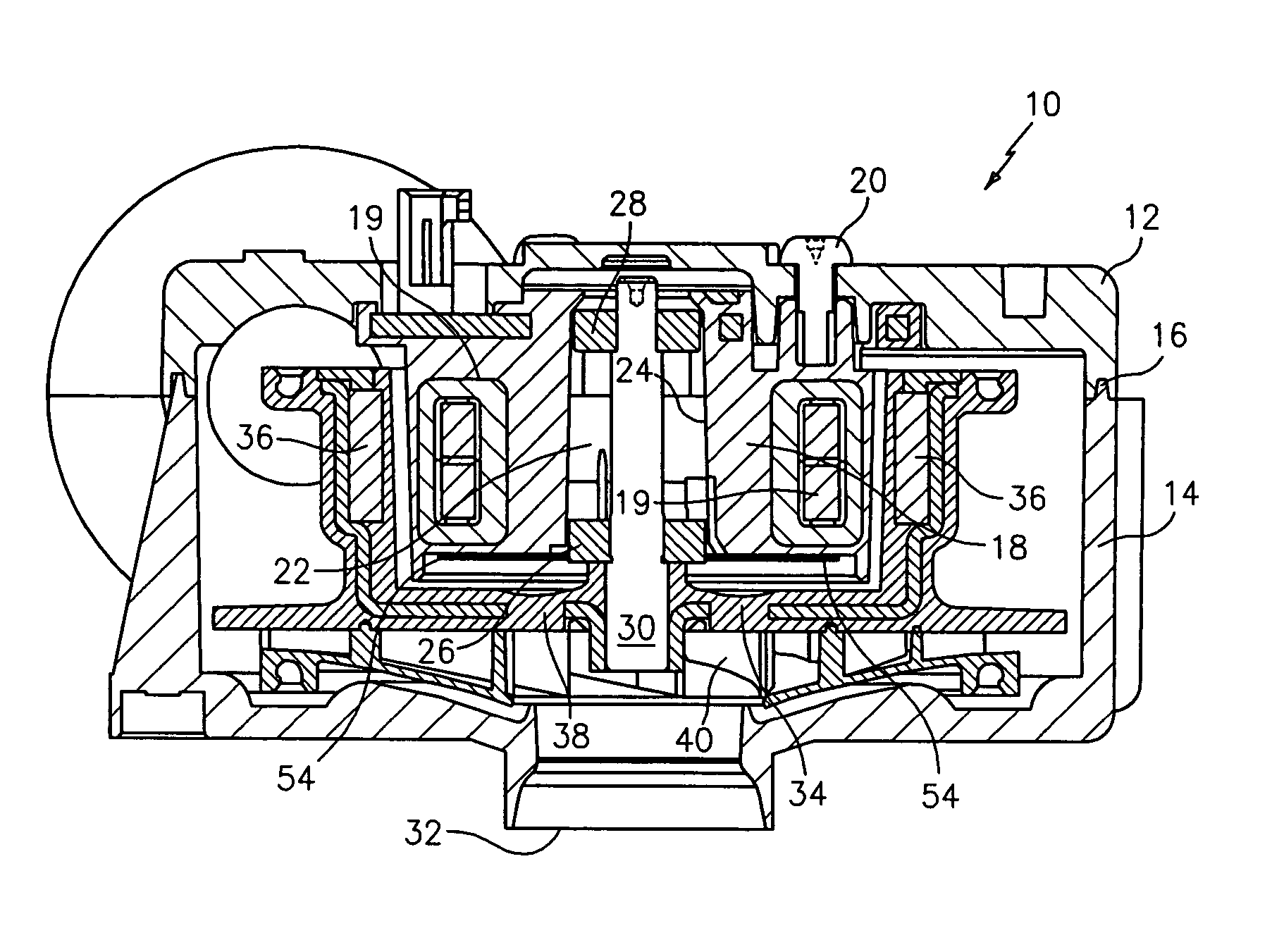

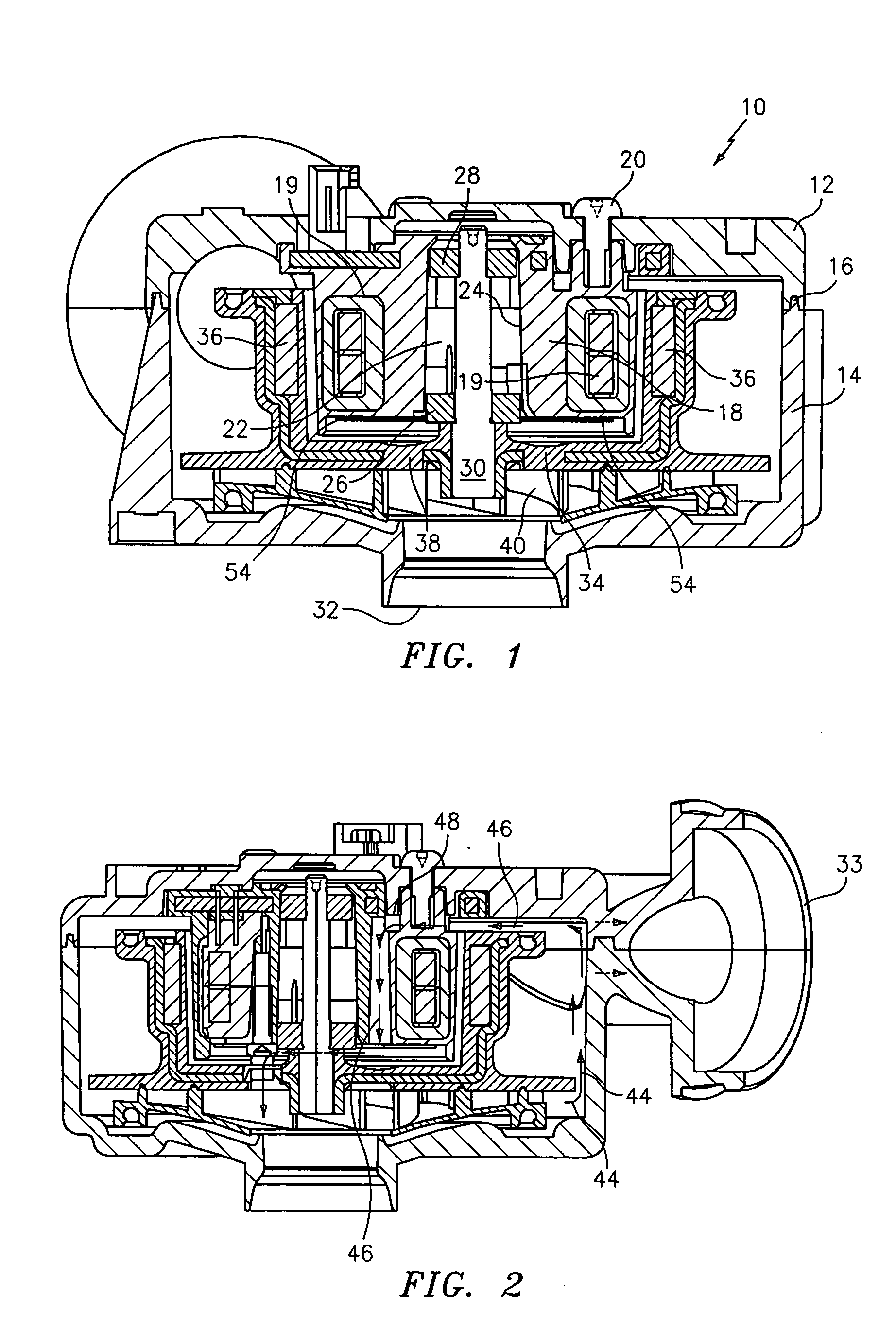

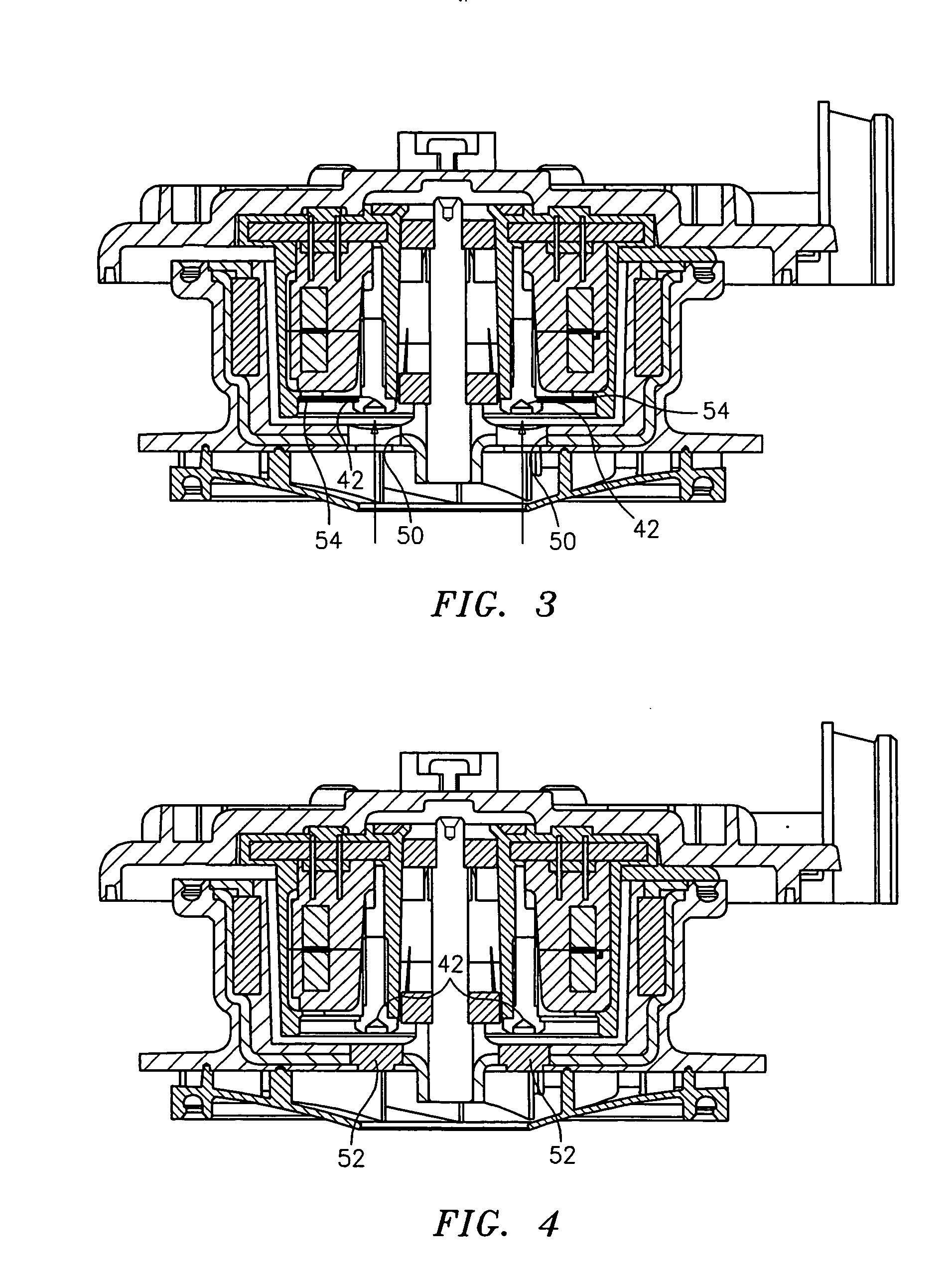

[0016] Referring to FIG. 1, a low part count blower-motor assembly is indicated generally at 10 and includes upper and lower parts 12 and 14. The parts are adapted for snap-fit engagement at a tongue and groove joint 16. The upper part 12 carries a stator assembly 18 attached to the housing by screws 20, 20 (one shown) and which may be conventional or which may follow the teaching of the above mentioned U.S. application Ser. No. 10 / 679,143. The stator is tubular with annular windings at 19 and a bearing tower 22, which may be constructed in accordance with the aforementioned U.S. Application 60 / 442,407, supported in its central opening 24 in turn carries front and rear bearing units 26 and 28. The bearing units 26, 28 journal a shaft 30 which projects downwardly from the central opening of the stator toward a fluid inlet opening 32 on the lower or second housing part 14. A discharge opening is formed cooperatively by the two housings parts 12 and 14 at 33.

[0017] Supported by the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com