Apparatus for single-wafer-processing type CVD

a technology of single-wafer processing and apparatus, applied in the direction of coating, metallic material coating process, chemical vapor deposition coating, etc., can solve the problems of reducing yield, contaminating semiconductor production lines, damaging semiconductor wafers, and generating particles, so as to achieve the effect of effectively preventing the deposition of unnecessary portions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

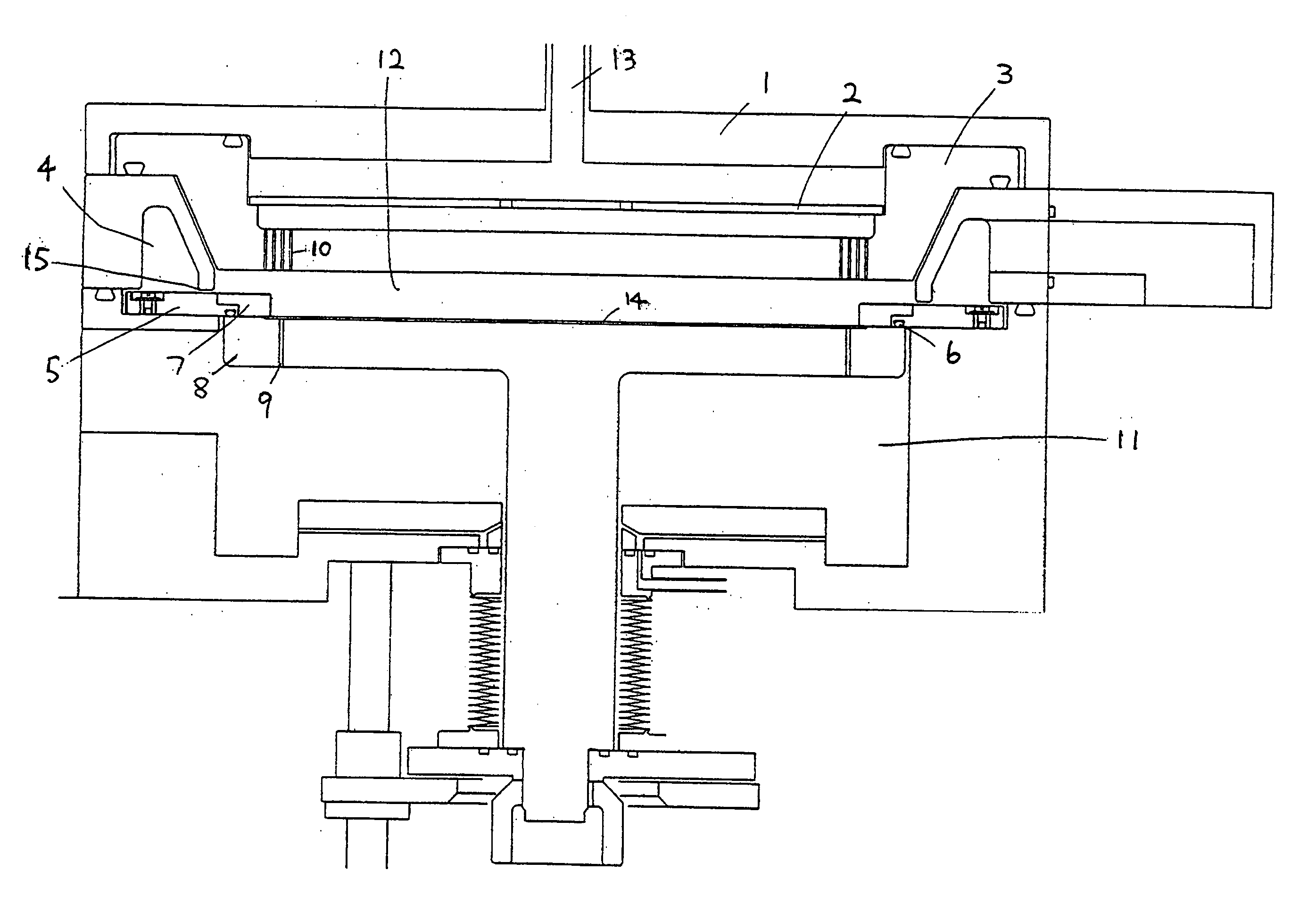

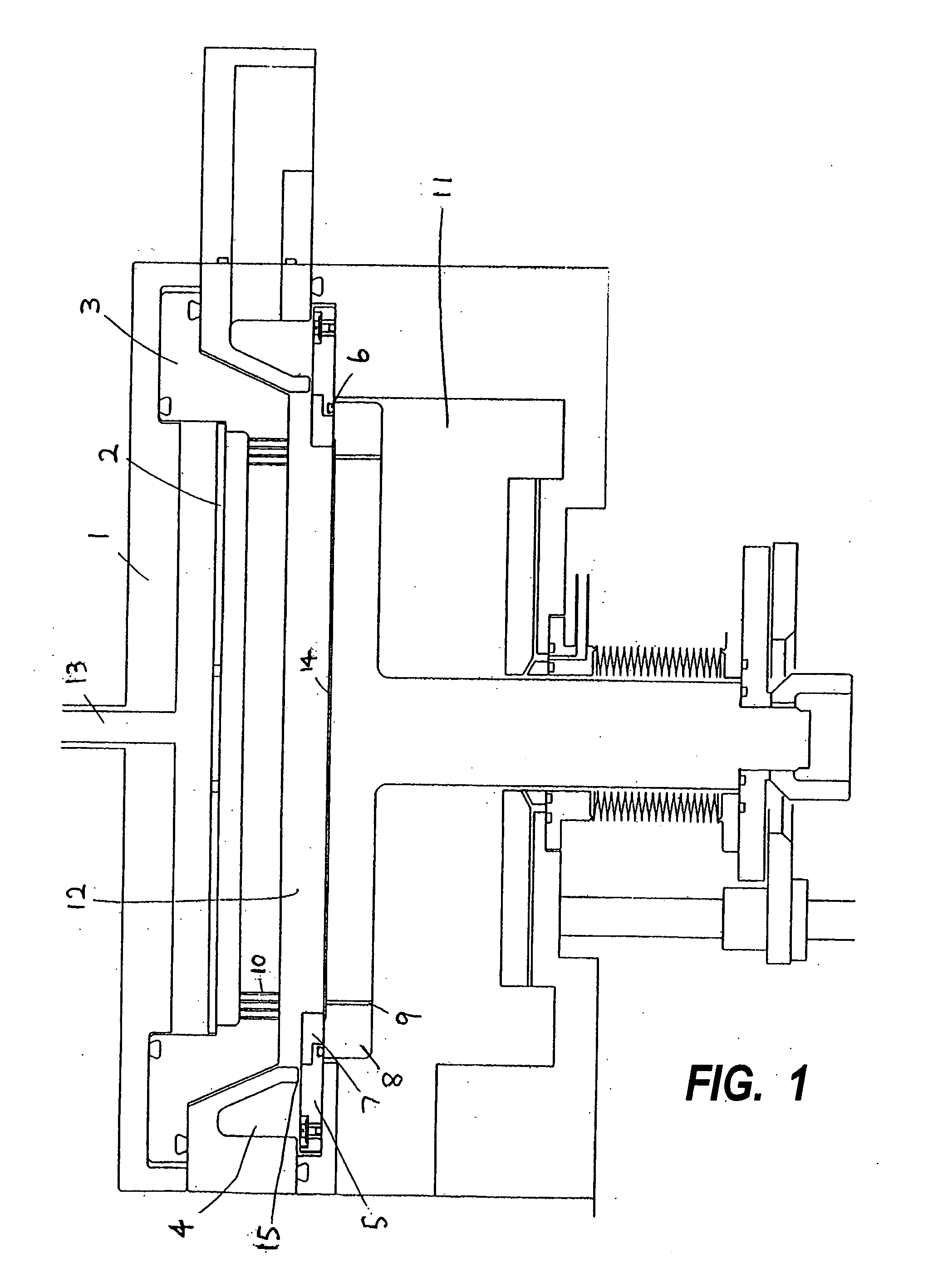

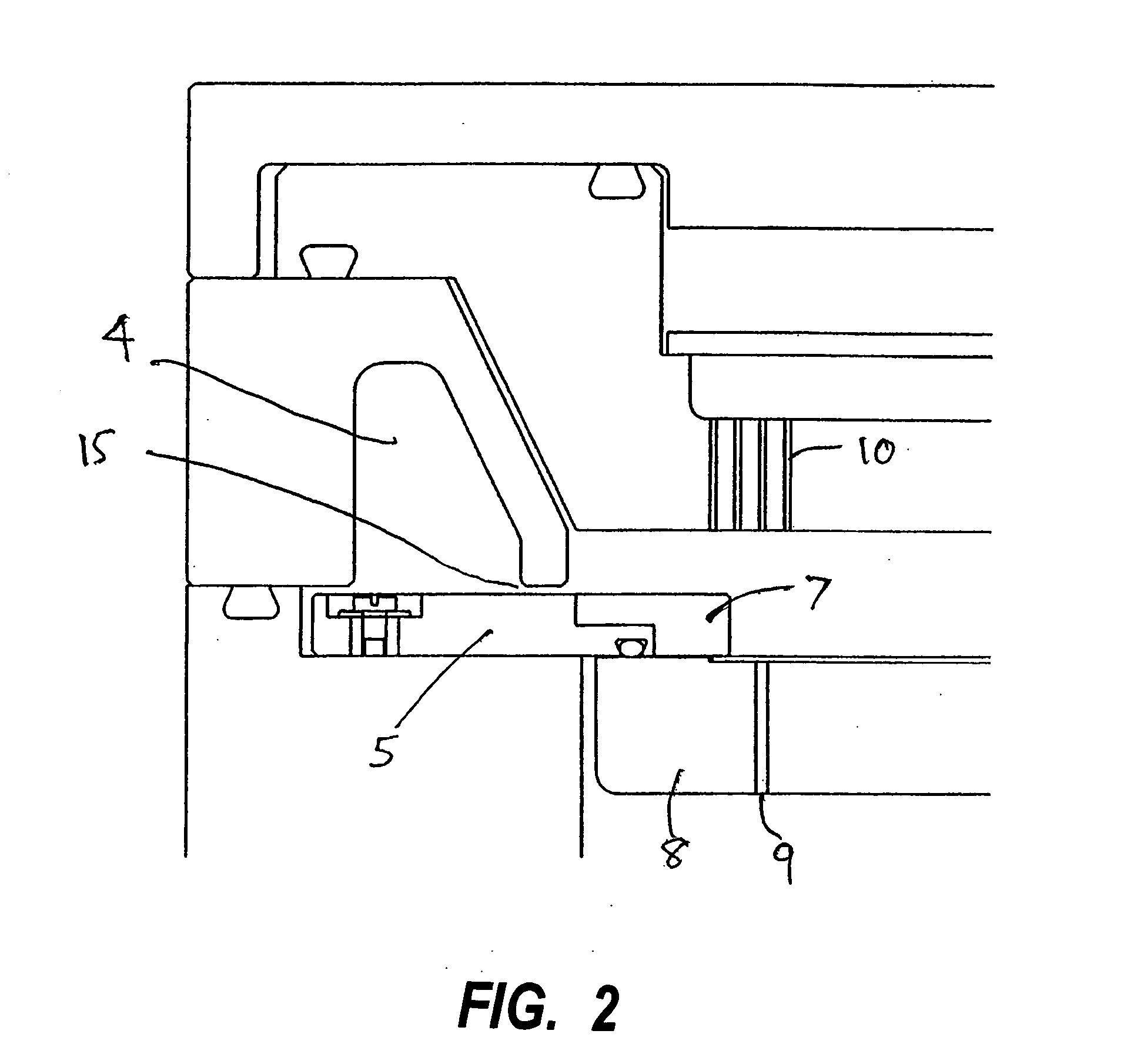

[0052] An embodiment of the present invention is described using Cu film deposition using the reactor shown in FIG. 1 as an example. After a semiconductor wafer is transferred from an evacuated load-lock chamber (not shown) to a susceptor 8, the susceptor is raised to a reaction position by a susceptor elevating means. At this time, the periphery of the susceptor is sealed by an O-ring provided at the lower portion of a separation plate 5, and the wafer-handling chamber 11, and the reaction chamber 12 are completely separated. At this time, the periphery of the wafer of 2 mm is completely covered by the guard ring 7. By supplying Ar from the wafer-handling chamber through holes 9 provided in the susceptor, deposition onto the back side and the edge of the wafer is prevented. After the susceptor is raised into the reaction chamber, 1000 sccm of inert gas is brought in from a gas inlet port 13. While the inert gas is emitted onto the wafer from holes 10 provided in the showerhead 3 a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com