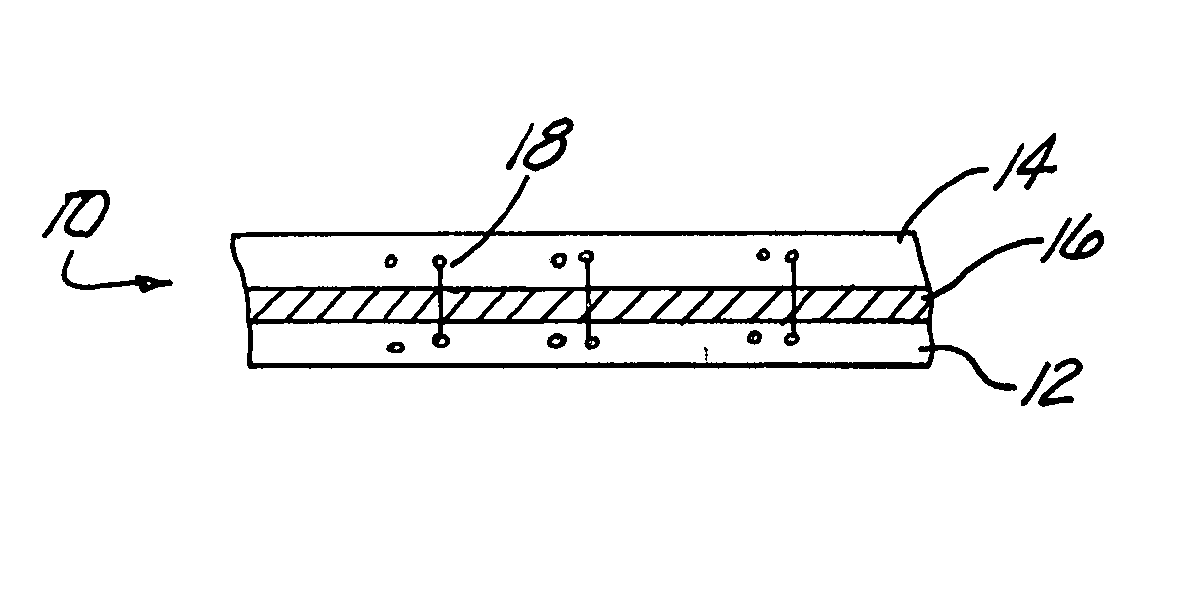

Sinuous composite connector system

a composite connector and composite technology, applied in the field of concrete sandwich walls, can solve the problems of low construction efficiency, high thermal conductivity, and high cost of construction, and achieve the effect of less skill and less construction cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

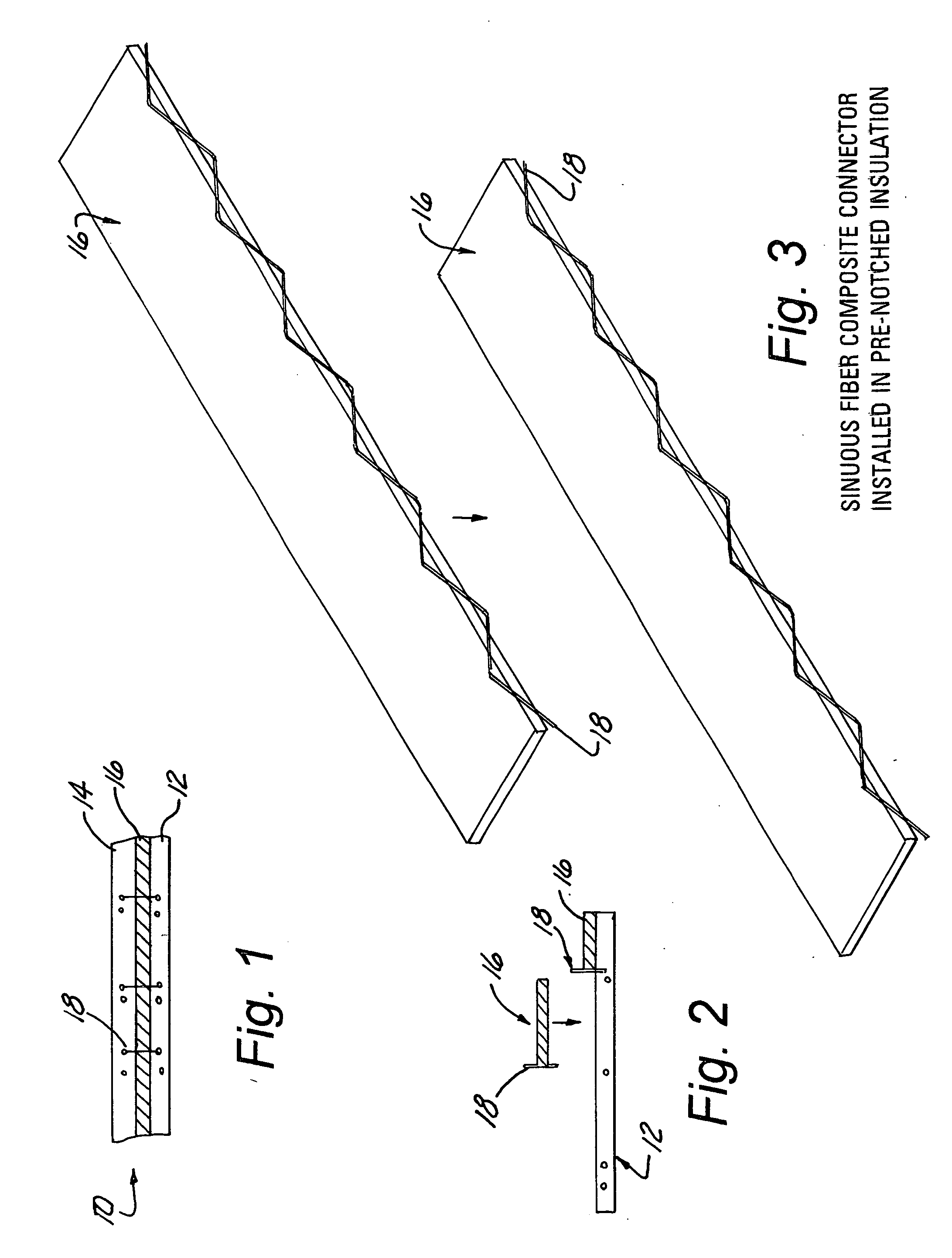

[0031] In a second embodiment, as shown in FIGS. 4-5, sinuous connecting elements 18 are attached to longitudinal reinforcing strands 20 that are located near the center of the future concrete layers. The sinuous connecting elements 18 are attached in such a manner that they extend approximately equal distances from the centerline of the future insulating layer. This attachment can be effected using wire ties or plastic clips that bind the sinuous connecting elements 18 to the longitudinal reinforcing strands 20. Multiple sinuous connecting elements 18 are installed across the width and the length of the form. A first layer of concrete 12 is placed in the form, and a relatively flexible insulating layer 16 is placed between the sinuous connecting elements 18. The second layer of concrete 14 is then placed. In this embodiment, the insulating layer 16 is flexible and resilient so as to be capable of deforming at the sinuous connecting elements 18 to form a seal around the elements and...

third embodiment

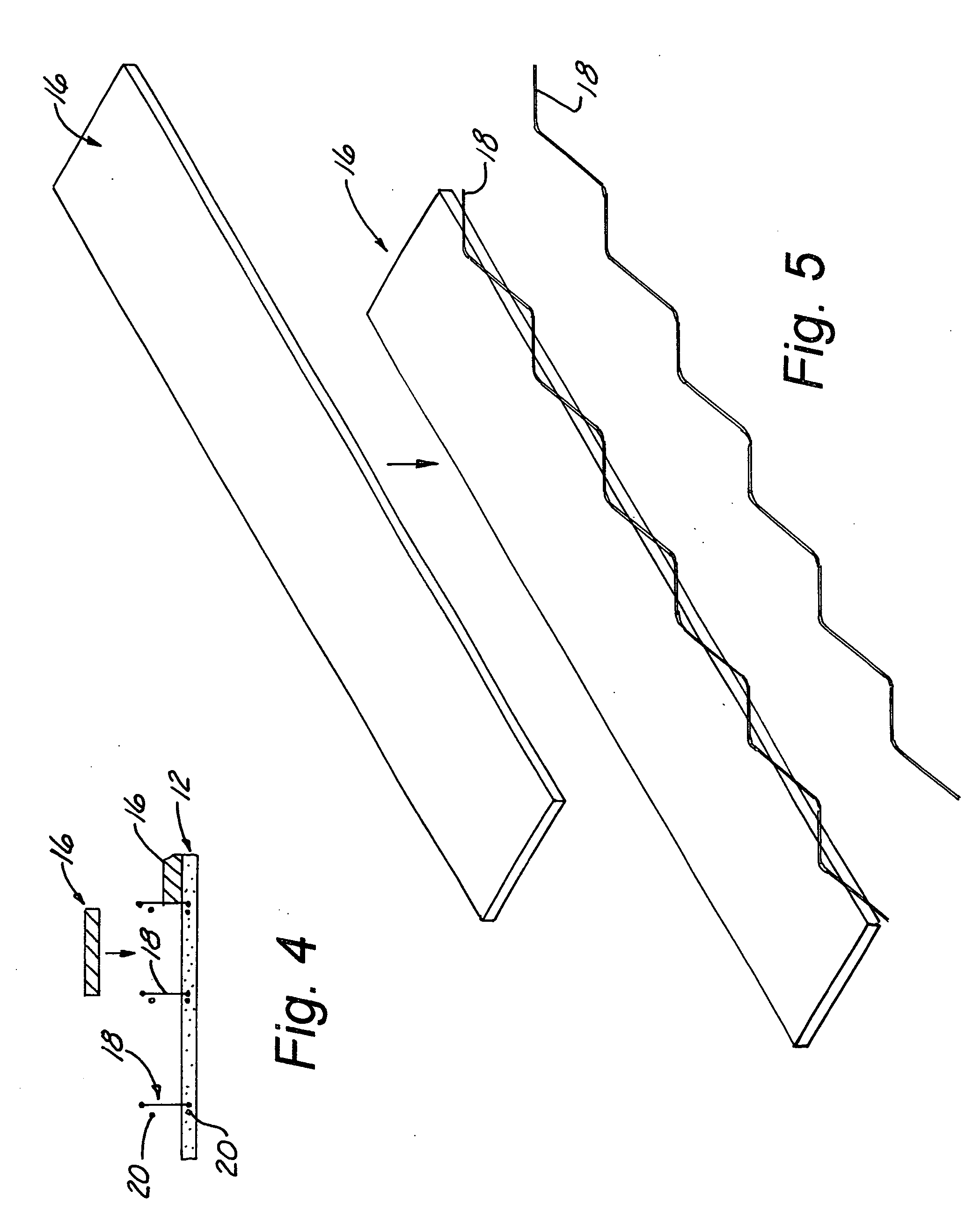

[0032] In a third embodiment, as seen in FIGS. 6-7, the order of the installation is altered. Initially, the longitudinal reinforcing strands 20 are in place in the first concrete layer 12 or both the first concrete layer 12 and the second concrete layer 14. After the first concrete layer 12 is placed in the form, flexible and resilient insulating strips 16 are installed. The sinuous connecting elements 18 are then pushed through the joints between the insulating strips 16. This may require that the form or the sinuous connecting elements 18 be vibrated during installation to allow the element to be pushed into the plastic concrete in the first layer of concrete 12. The sinuous connecting elements 18 will have depth indicators to allow the installers to gauge the depth of insertion of the elements. After insertion to the correct depth, the resilient insulating layer 16 will hold the elements at the proper depth while the second layer of concrete 14 is placed. This method is an advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com