Plastic micro packer and construction method using it

a technology of plastic micro-packers and construction methods, applied in construction, building repairs, building reinforcements, etc., can solve the problems of cracks in the outside or the inside of concrete structures or buildings, severe bad influences on the structure or building, and often falling off finished concrete layers, so as to prevent the separation of rubber sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will now be described in detail in connection with preferred embodiments with reference to the accompanying drawings. For reference, like reference characters designate corresponding parts throughout several views.

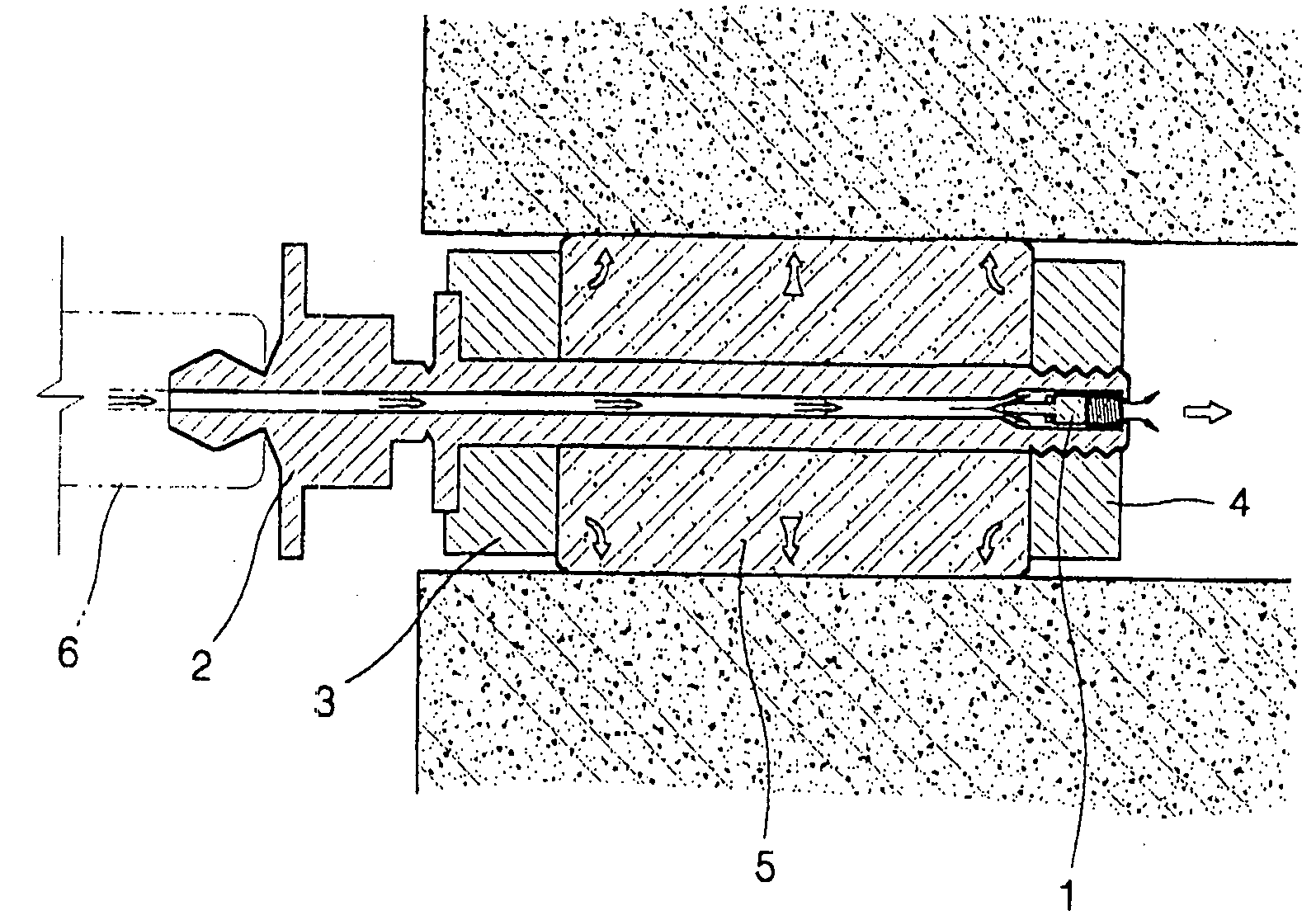

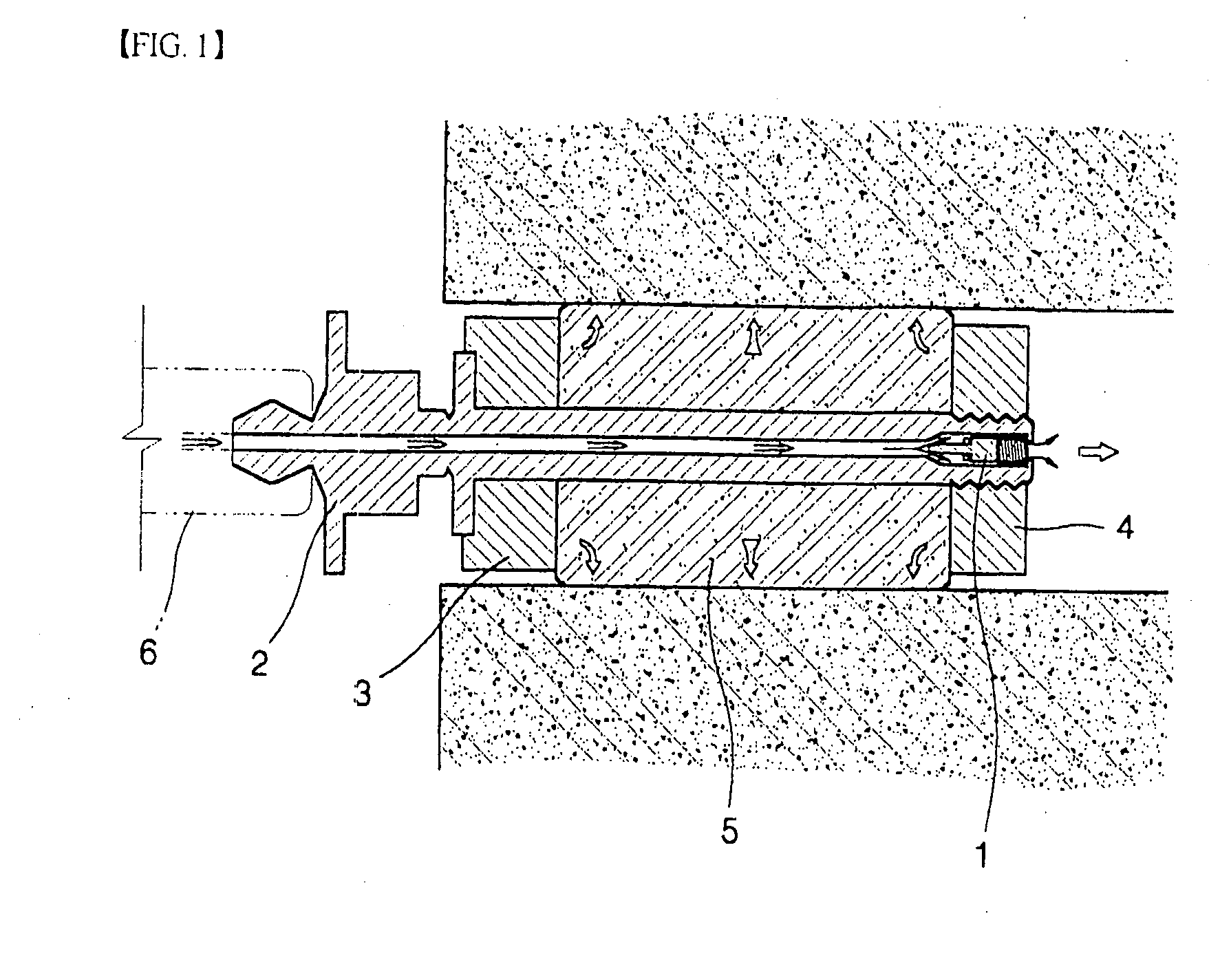

[0035] As shown in FIG. 4b, a plastic micro packer for repairing cracks of a concrete structure according to the present, invention is coupled to a hole 101 formed in a crack 110 to inject repairing solution 200 into the crack 110. The crack 110 communicates with the bottom surface of the hole 101.

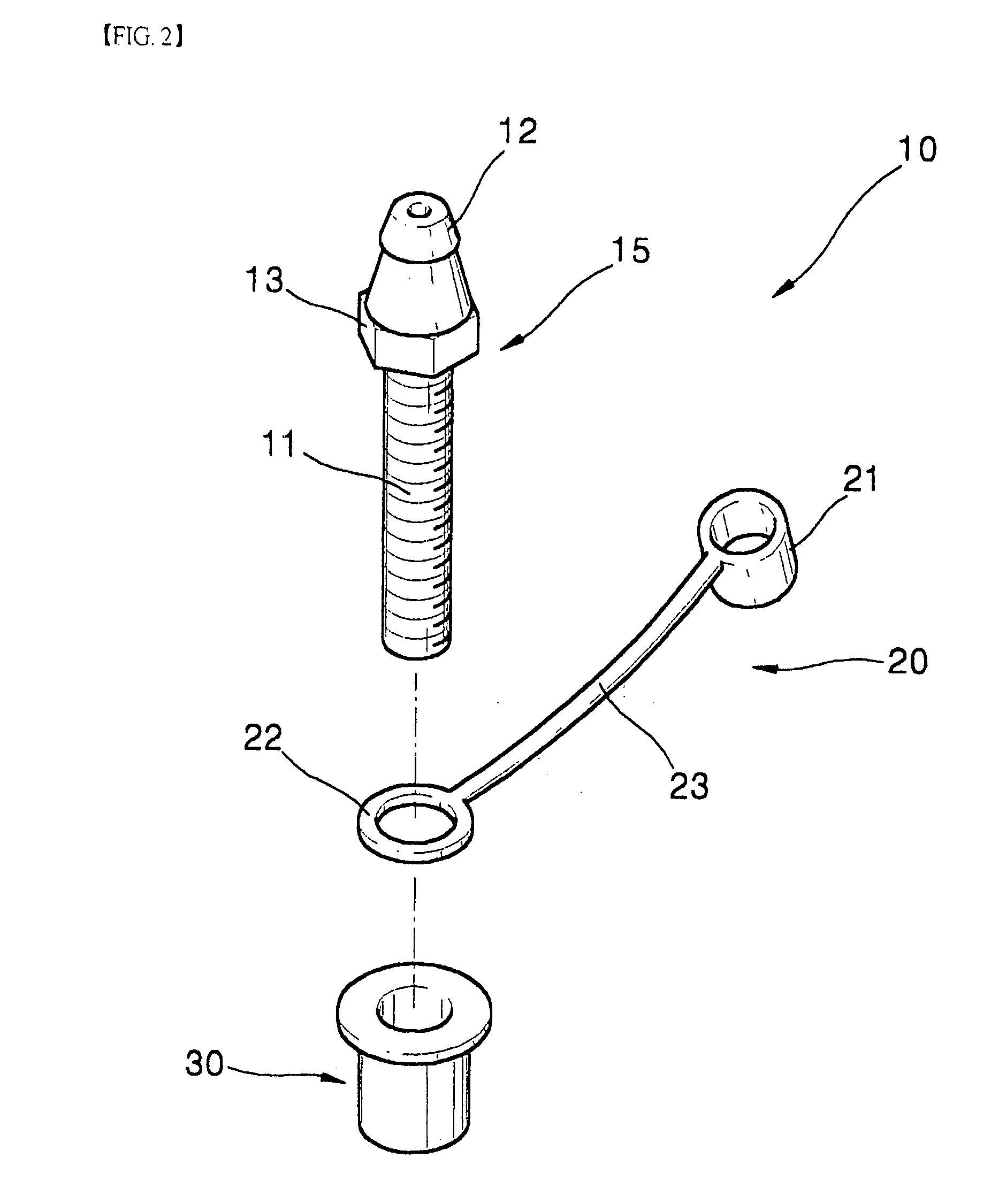

[0036] Referring to FIGS. 2 and 3, the packer 10 is coupled to the hole 101, and includes a hollow rubber sleeve 30 having a screw portion 31 formed on the inner surface, a hollow packer body having a screw coupling portion 11 screwed with the screw portion 31 and a nozzle portion 12 connected to a repairing solution injector 300 (see FIG. 4d), and a cover member 20 connected to the nozzle portion 12 to prevent leakage of the repairing solution 200....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com