Grip for makeup brush and method of manufacturing the same

a technology of makeup brushes and grips, which is applied in the direction of manufacturing tools, packaging foodstuffs, packaged goods, etc., can solve the problems of following up the taste of young customers who prefer novel designs, and achieve the effect of good strength and beauty appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

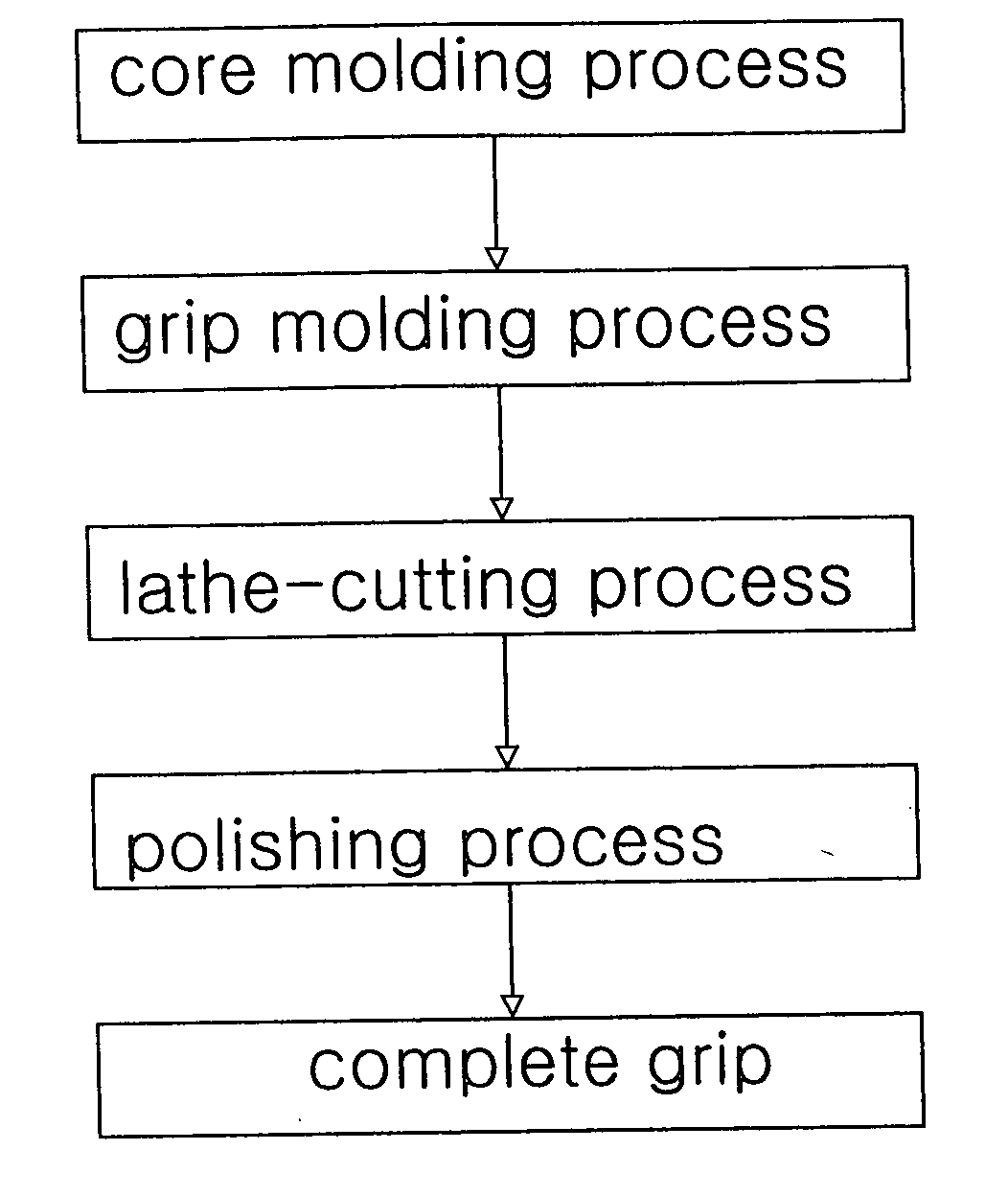

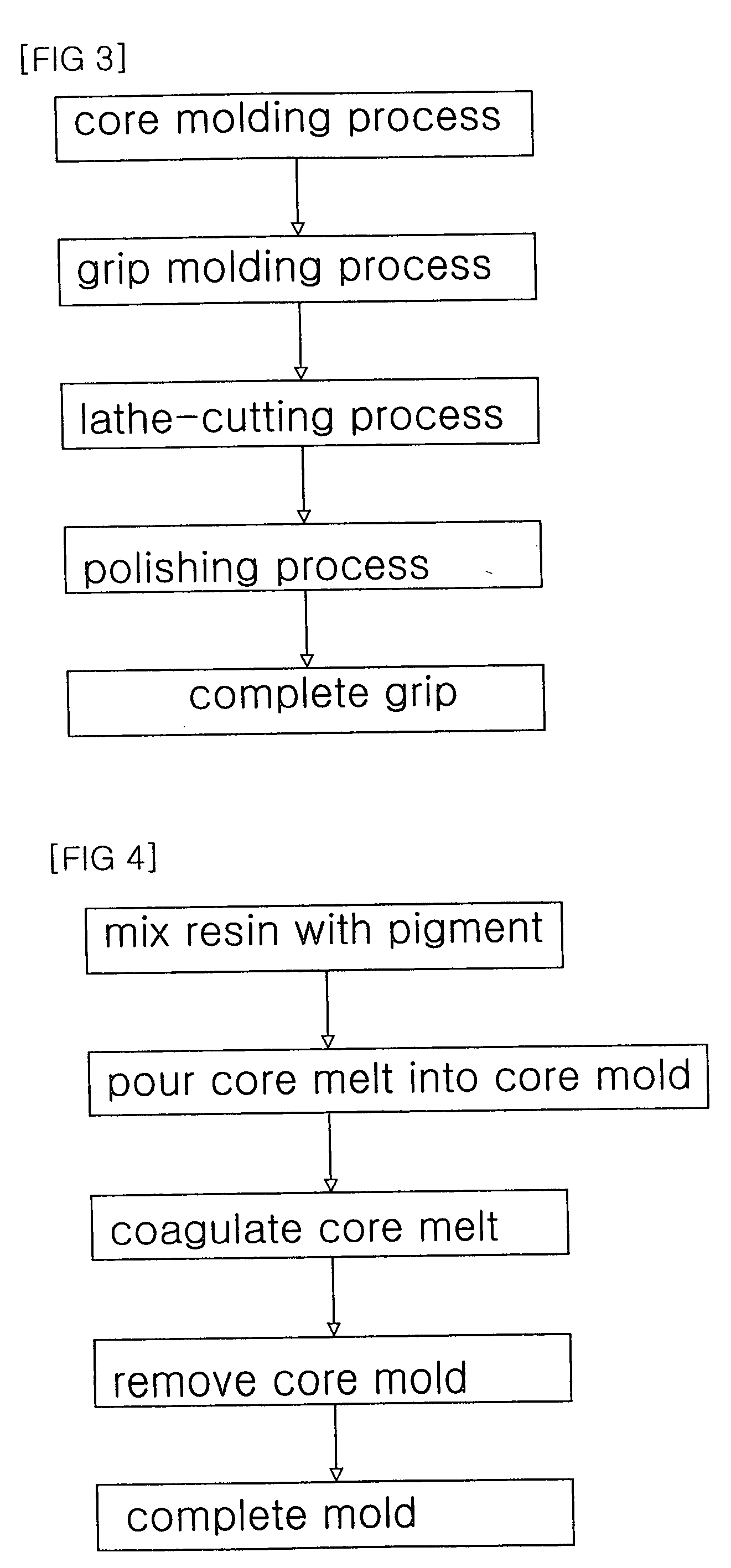

[0023] Hereinafter, the present invention will be described in more detail referring to the drawings, and characteristics and advantages of the present invention will be more clearly understood with the following detailed description.

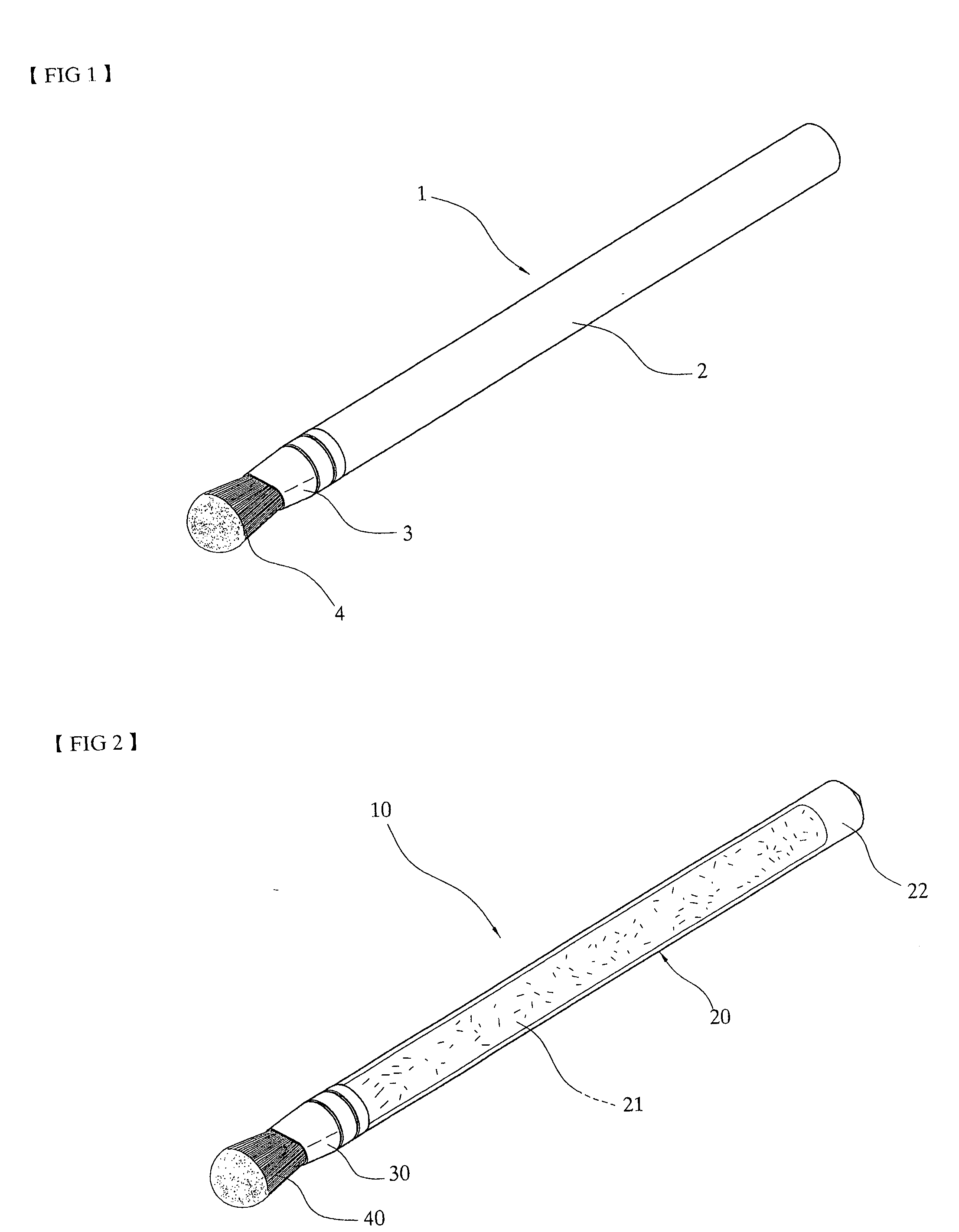

[0024] First, as shown in FIGS. 2, 9 and 10, a grip 20 for a makeup brush 10 according to the present invention includes a core 21 and a transparent resin layer 22.

[0025] The core 21 is made by molding resin mixed with a pigment to have a long circular bar shape and then included in the center of the grip 20 along a longitudinal direction of the grip 20. The resin used for molding the core 21 is preferably synthetic resin such as polyethylene and polypropylene.

[0026] The transparent resin layer 22 is formed at an outer surface of the core 21 as shown in the figures. This resin layer 22 is also made of polyethylene or polypropylene, and preferably the resin layer 22 is transparent so that the core 21 inside the grip 20 can be seen from outside. Also, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com