Modular core wall construction system

a construction system and module technology, applied in the direction of construction, building components, electrical equipment, etc., can solve the problems of inflexible spatial arrangement, difficulty in transporting prefabricated “boxes of air” from the fabrication site to the installation site, and different businesses face considerable competition, so as to improve building efficiency, flexibility, cost effectiveness, and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

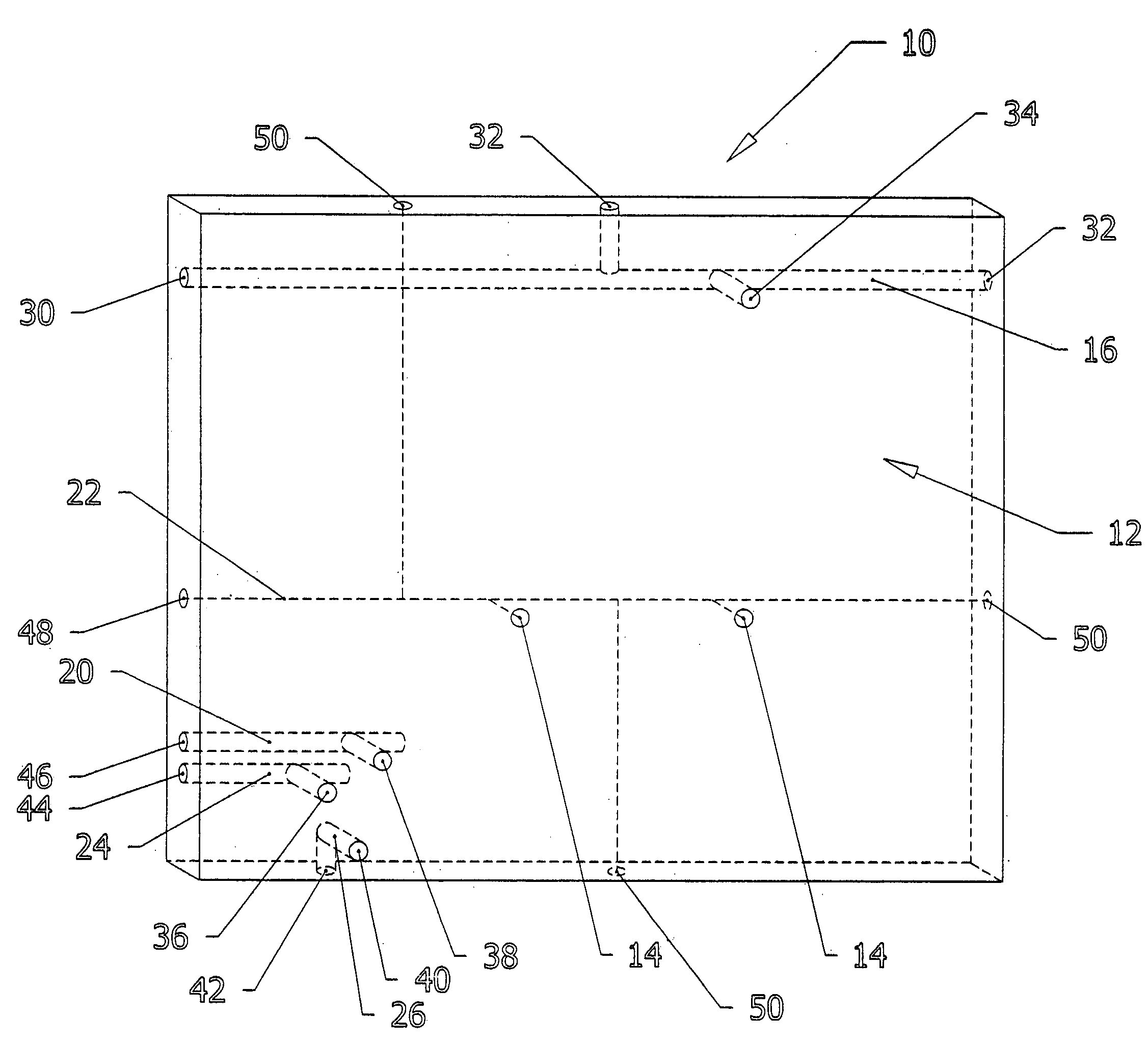

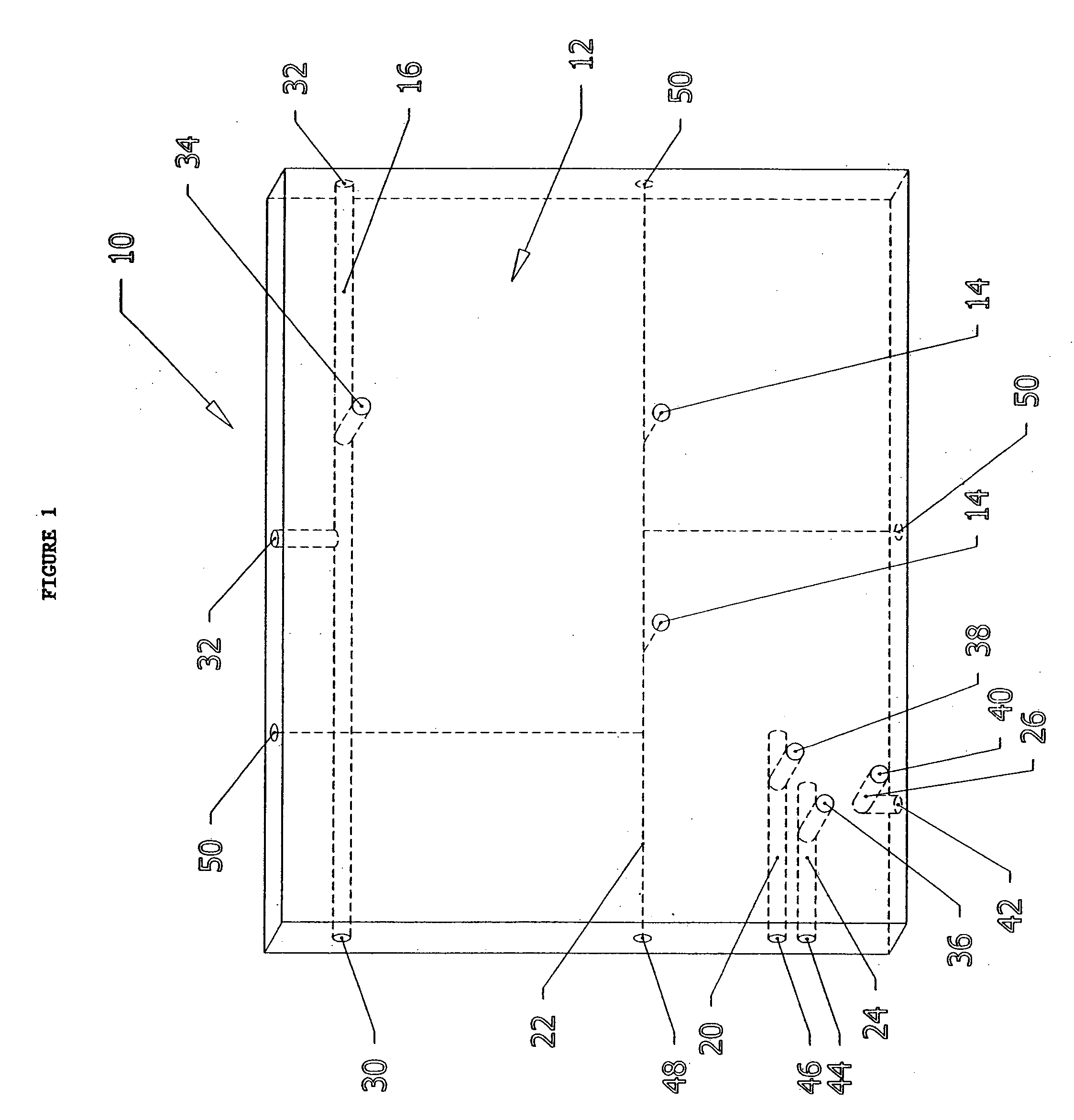

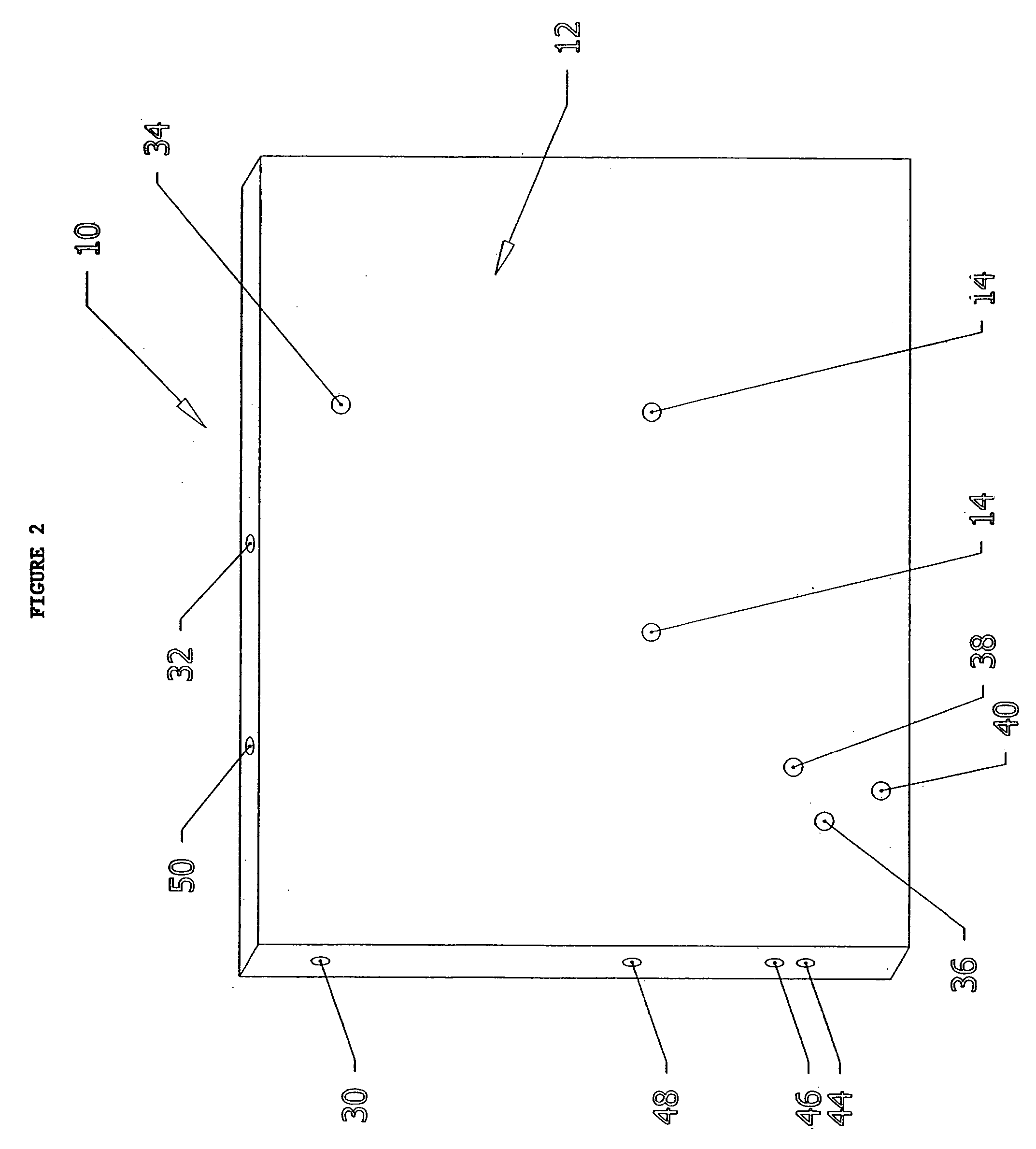

[0026] The present invention is directed to flexible systems for building construction wherein a building's utilities are distributed from a prefabricated core wall and are managed by a computer-based controller that is located in the core wall. The core wall modules are self-contained and include plumbing, wiring, ventilation, etc., thereby providing a flexible spatial layout of both utility intensive rooms, such as kitchen and bathroom, and other rooms of a building. Moreover, the system's flexibility allows for the building's interior layout to expand or contact around the core wall as required by a particular architectural plan. The prefabricated core wall and panelized partitions of the present invention are suitable for use in modular or conventional construction, can be produced in a variety of finishes or unfinished, and can be manufactured and shipped with or without common residential appliances and fixtures, such as sinks, tubs, toilets, cabinets, etc. The most common use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com