Golf balls containing cis-to-trans converted polybutadiene and methods for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

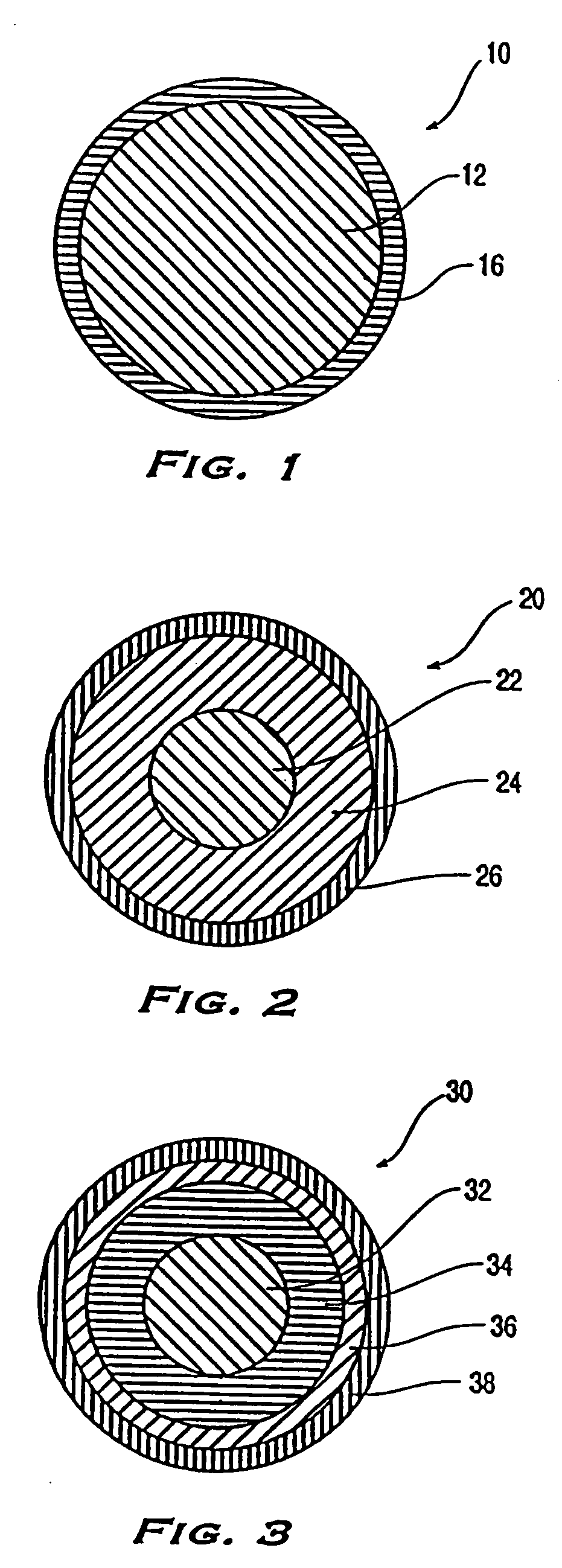

[0016] A golf ball in accordance with the present invention has a solid core. Suitable solid core golf balls include one-piece golf balls, two-piece golf balls having a core and a cover surrounding the core and multilayer golf balls having a core made up of one or more substantially concentric intermediate layers and a cover surrounding the core and made up of one or more layers that are also substantially concentric with the core. At least one of the core or cover layers is formed from polybutadiene that has relatively high trans content and low vinyl content. In addition to butadiene rubber, golf balls in accordance with the present invention can be formed from isoprene rubber and natural rubber.

[0017] In one embodiment, high cis, low vinyl butadiene rubber, preferably having a high molecular weight and low polydispersity and low branching is converted after polymerization and in solution to a butadiene rubber having a trans content that is higher than the trans content before co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com