Automated shipboard material handling and storage system

a material handling and storage system technology, applied in the direction of passenger handling apparatus, special purpose vessels, ways, etc., can solve the problems of not being able to easily retrieve a specified container, current container ship load handling or transfer system, and inability to retrieve, so as to facilitate efficient loading and offloading, reduce the amount of effort and manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

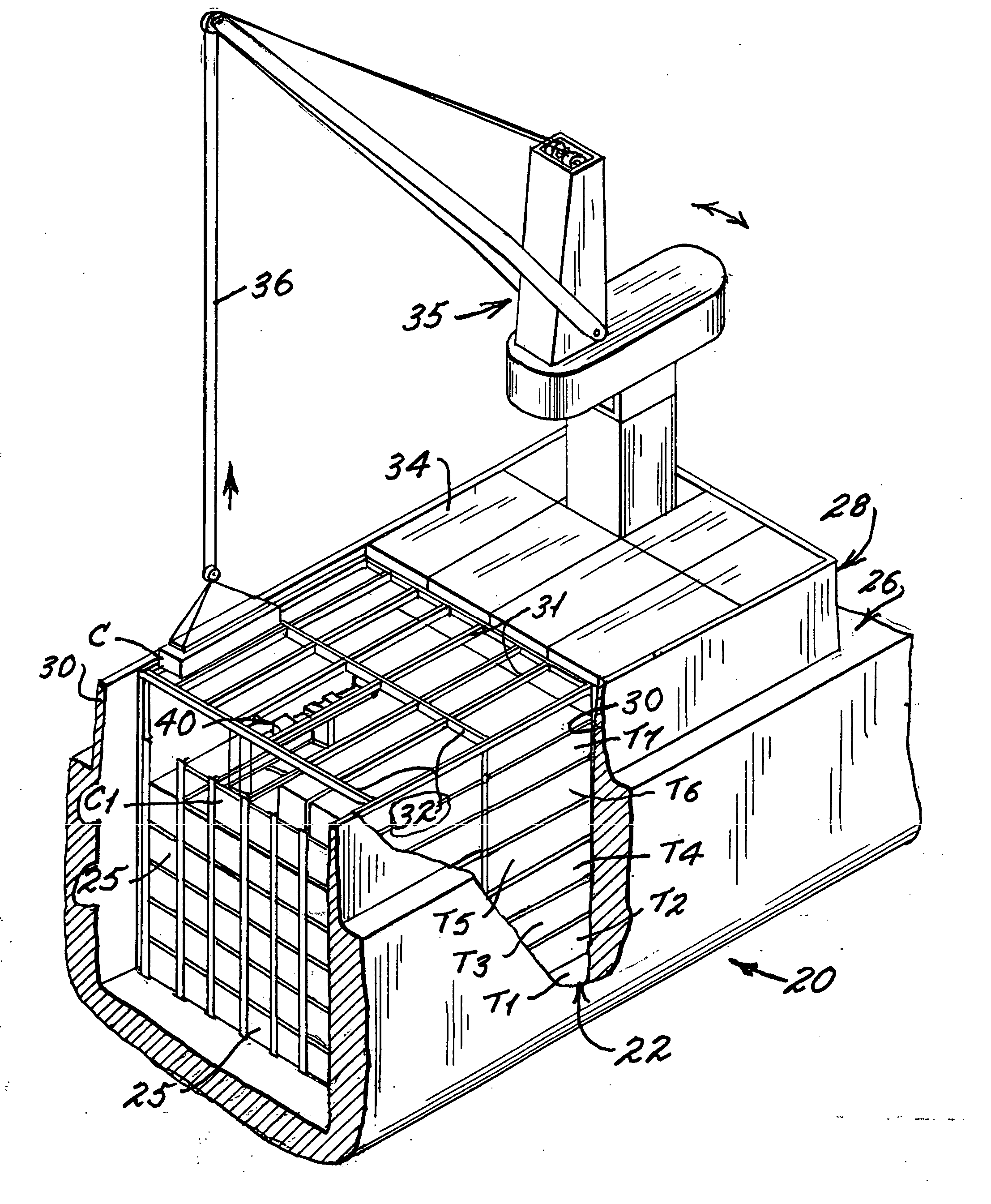

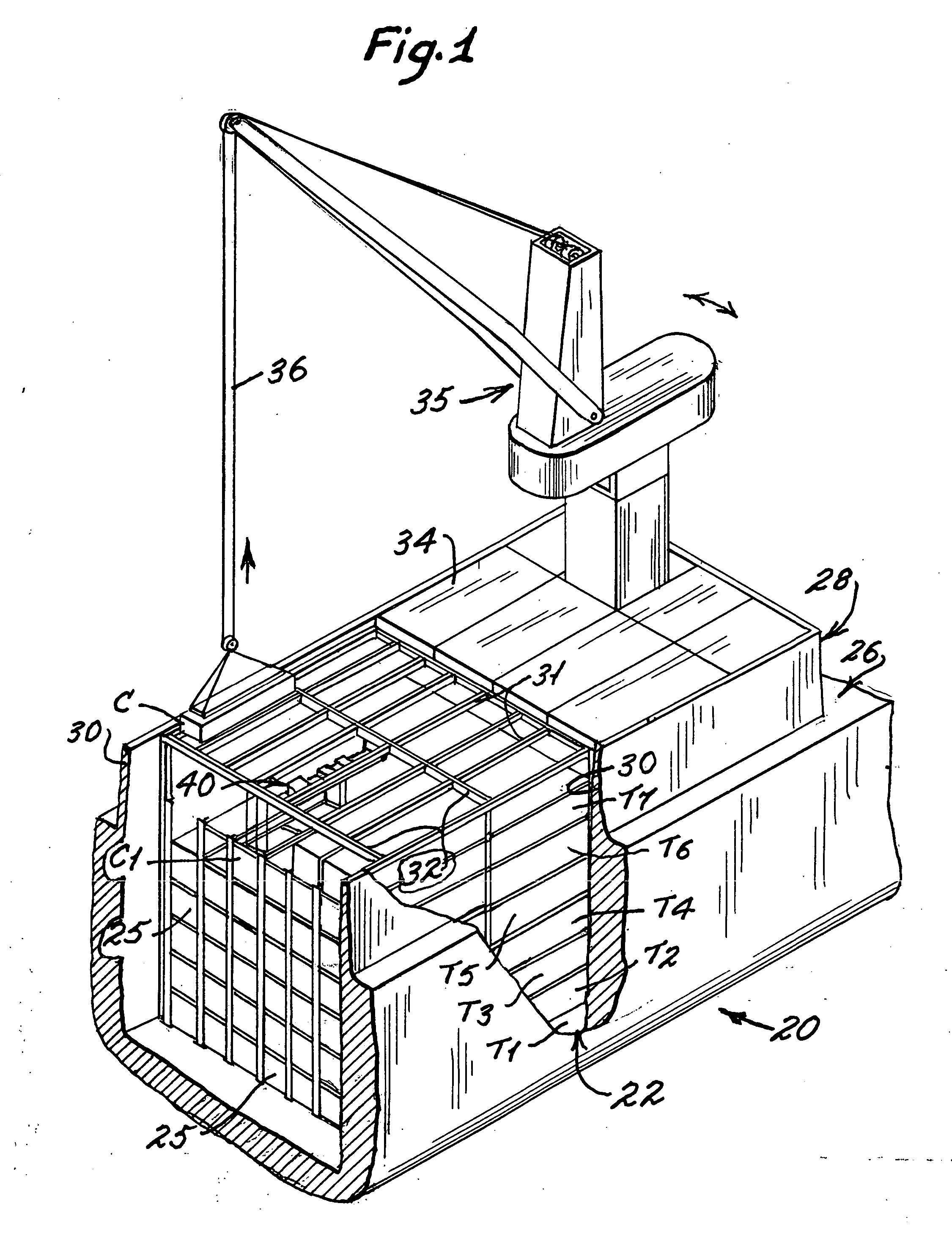

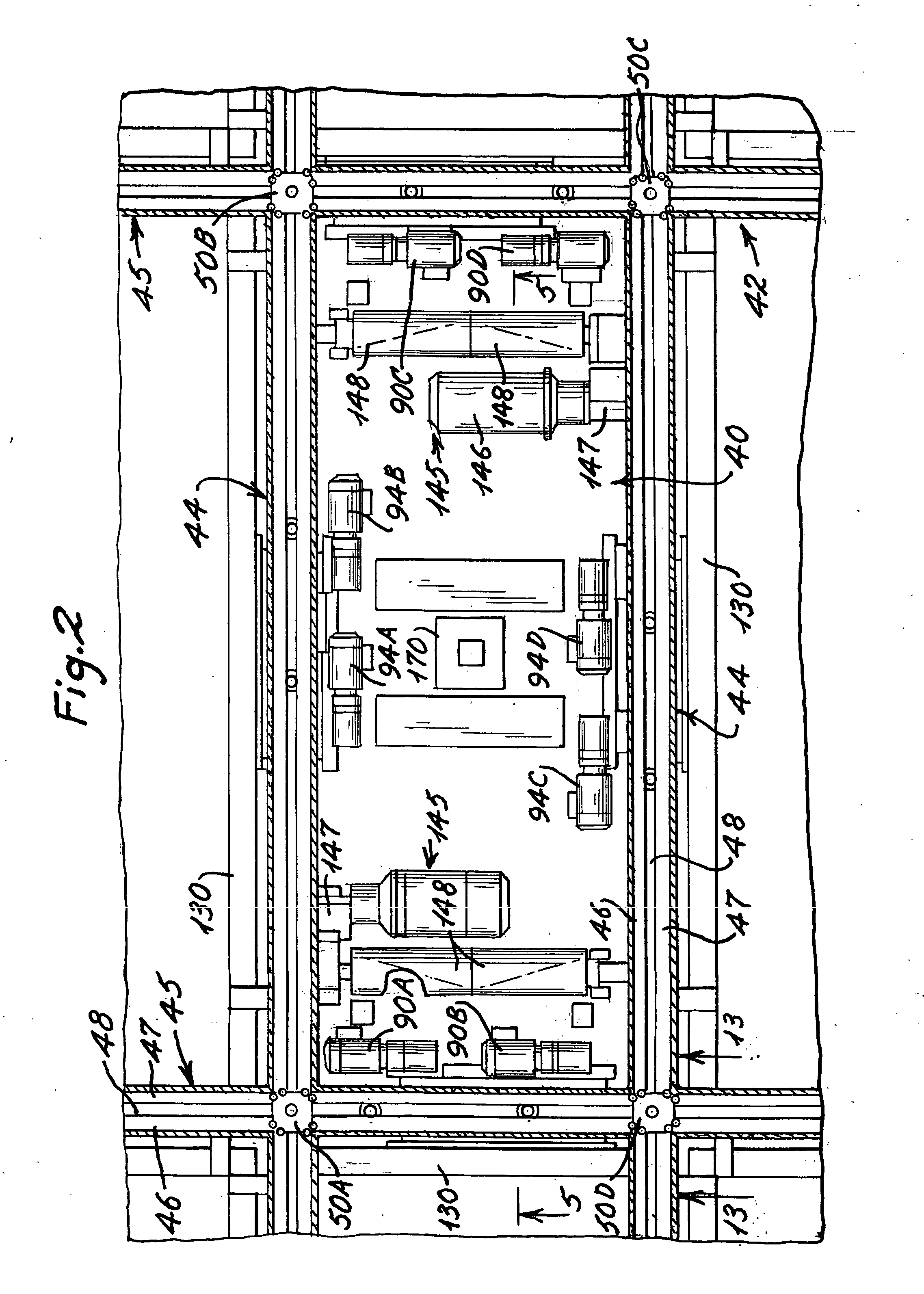

[0036] With specific reference to FIG. 17 of the drawing figures, the system of the present invention will be described in association of a container ship 20. It should be noted that the system may be used in other non-shipping environments such as mini-warehouses, distribution warehouses, garages and the like. The container ship is shown in cross section at the central portion so as to illustrate four hold areas 21, 22, 23 and 24 each of which is divided into a plurality of vertically tiered cells 25. The cells are defined by vertically and horizontally extending steel beams which are generally of a size to allow a conventional standardized cargo container to be restrained within each cell in a conventional manner well know to those in the art. With the invention, however, the upper portion or upper tier of cells shown at T7, as opposed to being situated on the deck 26 of the vessel, are actually seated on top of each tier of cells within an enclosure 28 defined by steel plates whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com