Lubrication free connection

a technology of self-lubricating shaft and pivot pin, which is applied in the direction of combs, buttons, other domestic objects, etc., can solve the problems of constricting the internal diameter of the plastic sleeve, and achieve the effect of sufficient material for wear, increased adhesion, and inability to reduce the internal diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

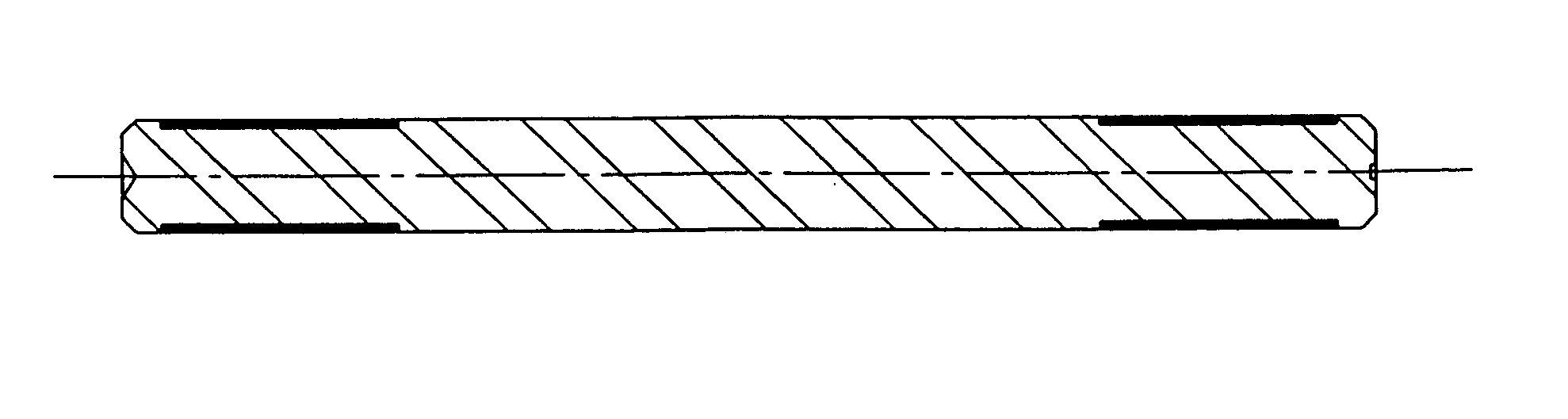

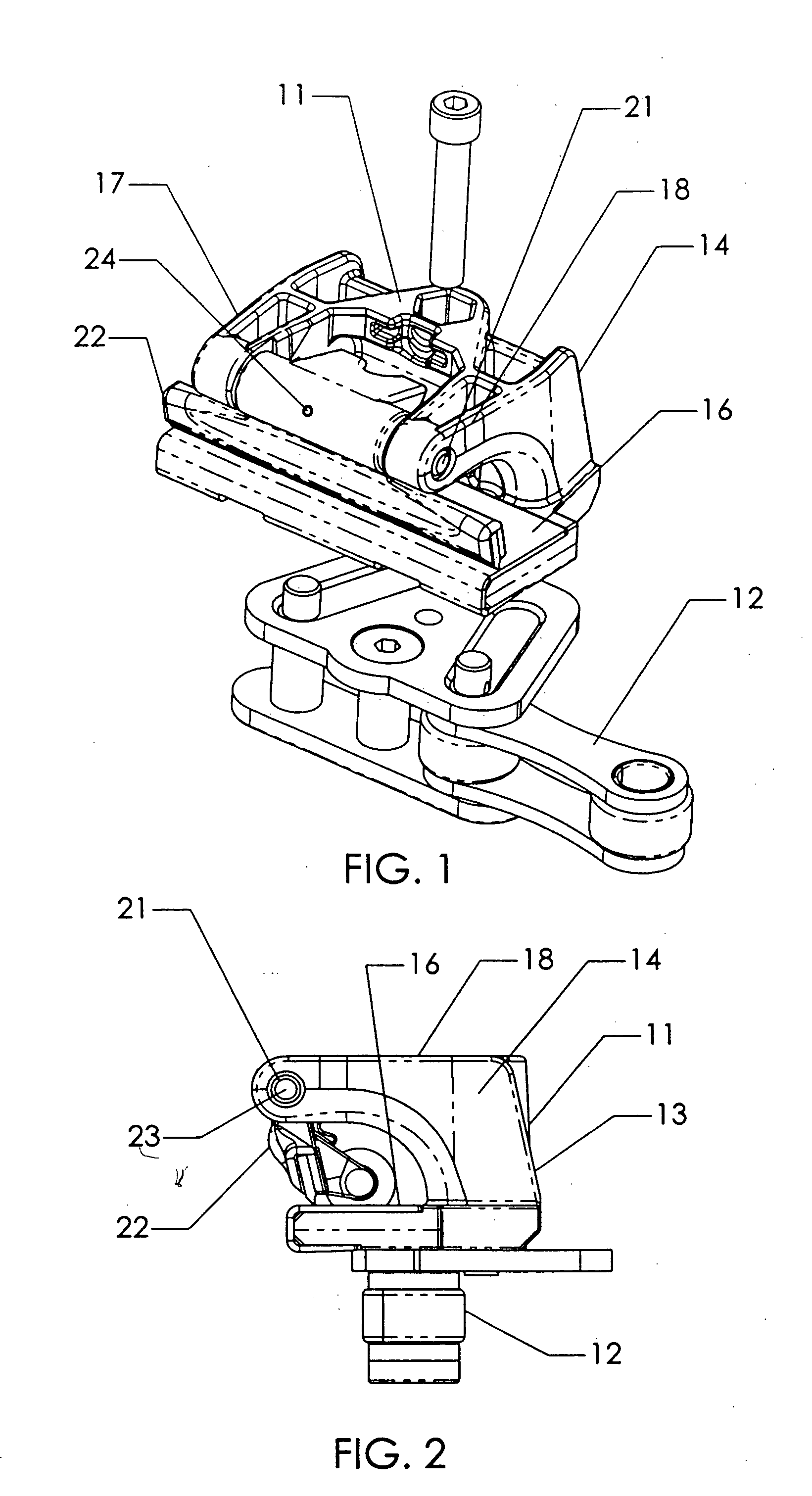

[0018] Referring to FIGS. 1 and 2, the invention is illustrated in a tenter clip 11 which with other clips, are connected in series by a link chain 12 thus providing a tenter chain 13. Tenter chains are provided in opposing pairs to grip the edge of a continuous web of flat material such as woven cloth and to simultaneously stretch the material in a transverse direction while conveying it through a process oven as a finishing operation to its manufacture.

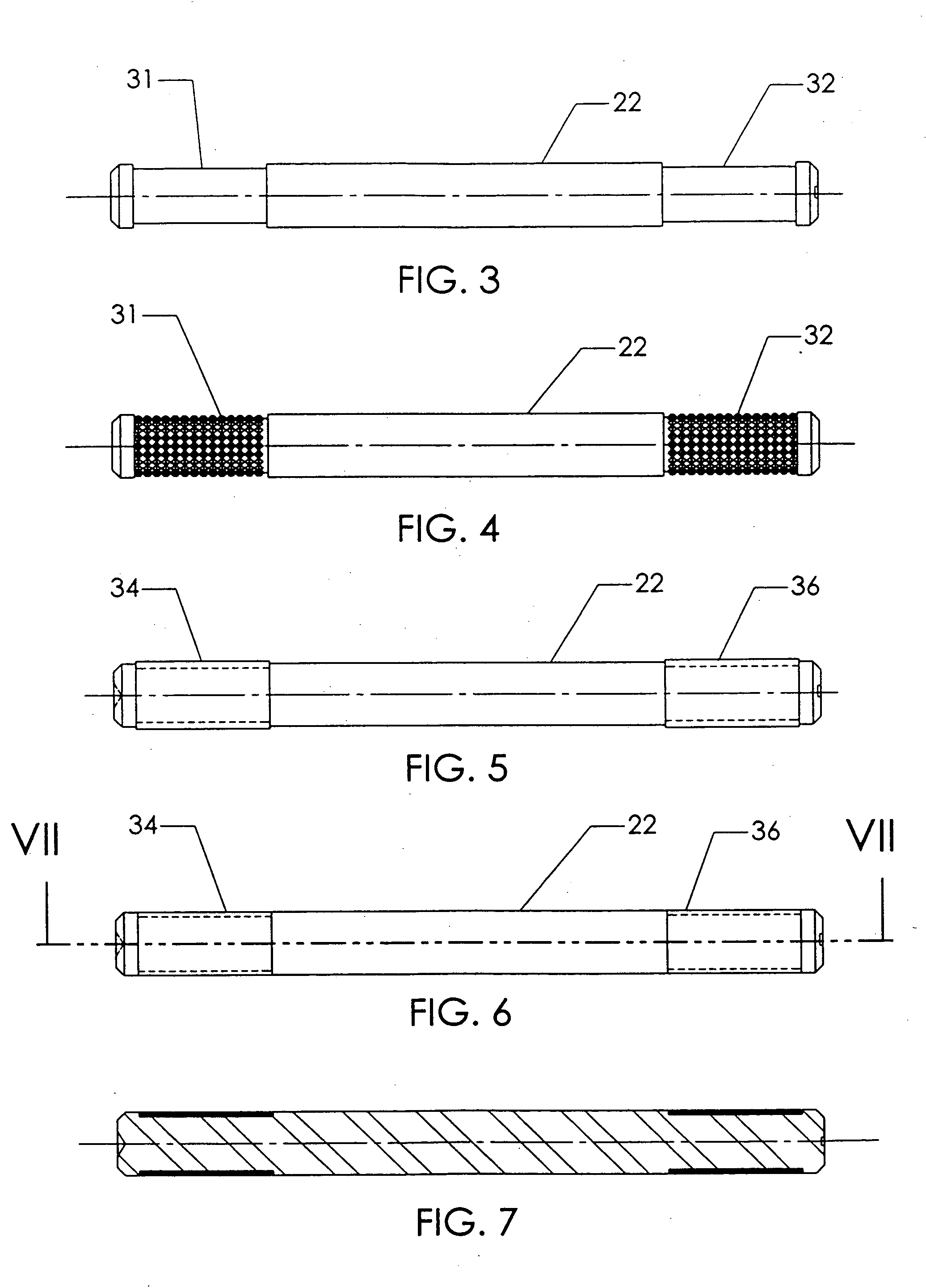

[0019] The tenter clip 11 is a clamping device which includes a clip body 14 which is open on one side with a surface 16 for supporting web material being fed into it. The clip body 14 includes a pair of support arms 17, 18 pivotally supporting a pivot pin 21 for a jaw 22. The pivotable jaw 22 is operated by an external mechanism, not shown, to allow entry and exit of the web material. The jaw 22, and the clip 11, are designed to automatically clamp and hold the web material. The jaws movement is a limited pivotal movement about th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| axial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com