Roofing system, roof panel therefor, and method of assembling a roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

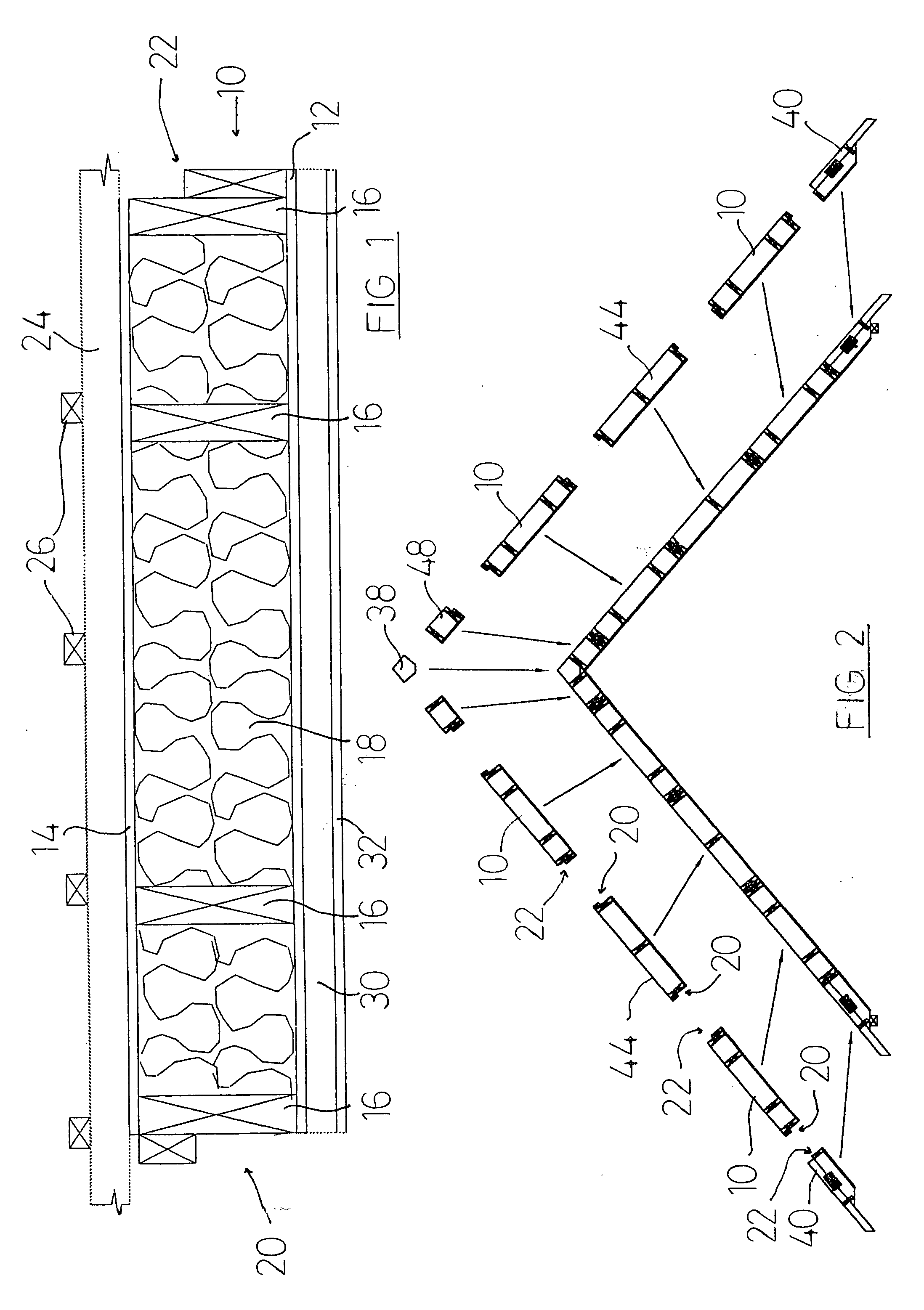

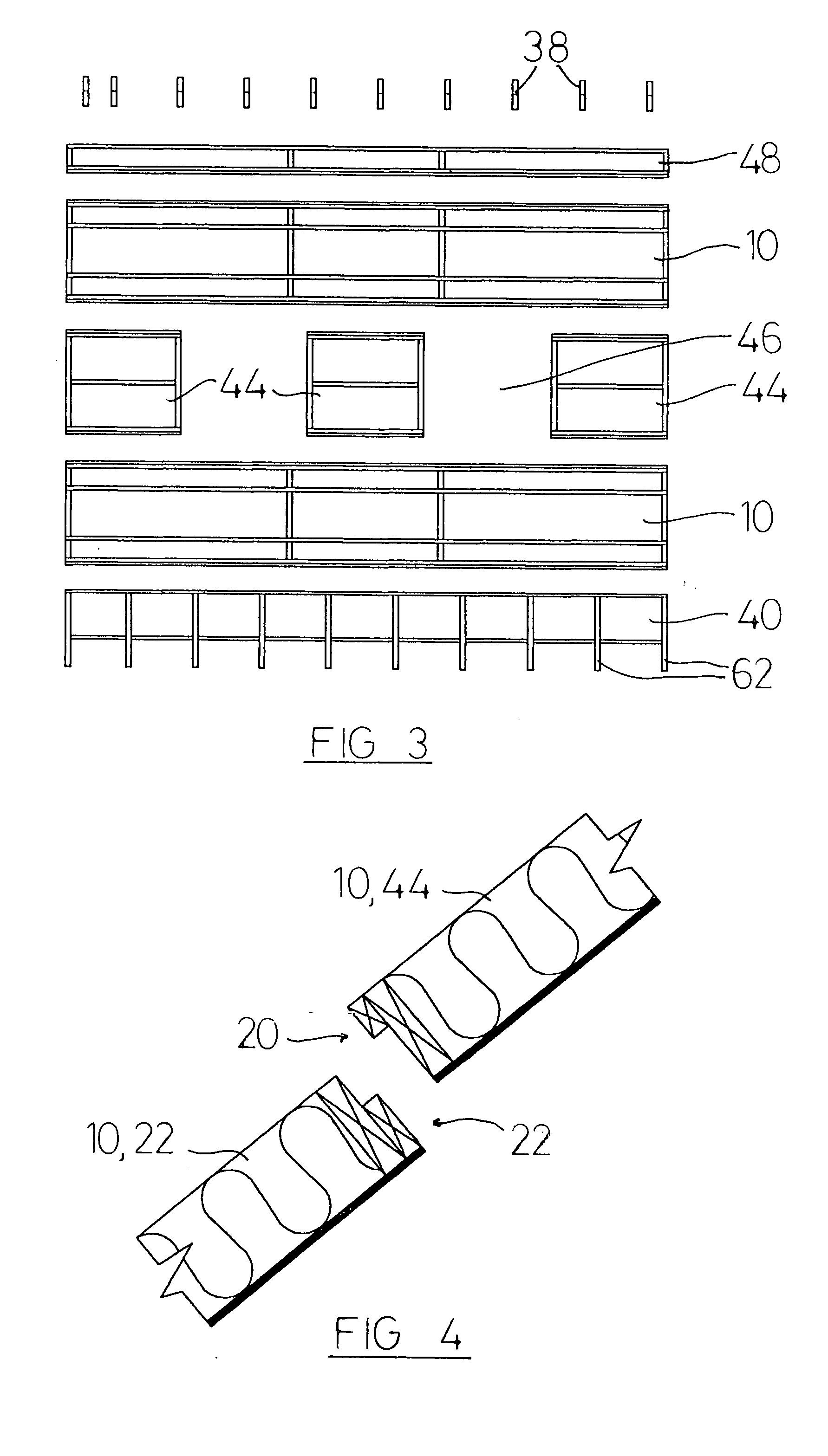

[0037]FIG. 1 shows a cross-sectional view of a roof panel 10. The panel comprises a first sheet 12 (which is the innermost sheet in use), and a second sheet 14 (which is the outermost sheet in use), which are interconnected by four longitudinal beams 16. Insulating material 18 fills the volume between the sheets 12 and 14 which is not occupied by the beams 16.

[0038] It is desirable but not essential that the panels be made from renewable and recyclable materials, and natural materials such as wood are preferred. In this (preferred) embodiment the beams 16 are of wood, the sheet 12 is of plywood, and the sheet 14 is of fibreboard. The beams 16 in this embodiment have cross-sectional dimensions of approximately 50 mm by 197 mm, and the sheets 12, 14 are approximately 12 mm thick.

[0039] To ensure the required weatherproofing, the outermost sheet 14 includes a weatherproof material, and preferably a “breathable” material; in this embodiment, therefore, the sheet 14 comprises a sheet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com