Slide member and method for producing the slide member

a technology of slide member and slide member, which is applied in the direction of valve arrangement, machine/engine, mechanical apparatus, etc., can solve the problems of unsatisfactory retention and failure to effectively prevent the occurrence of abrasion, and achieve the effect of reducing the resistance of the slid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

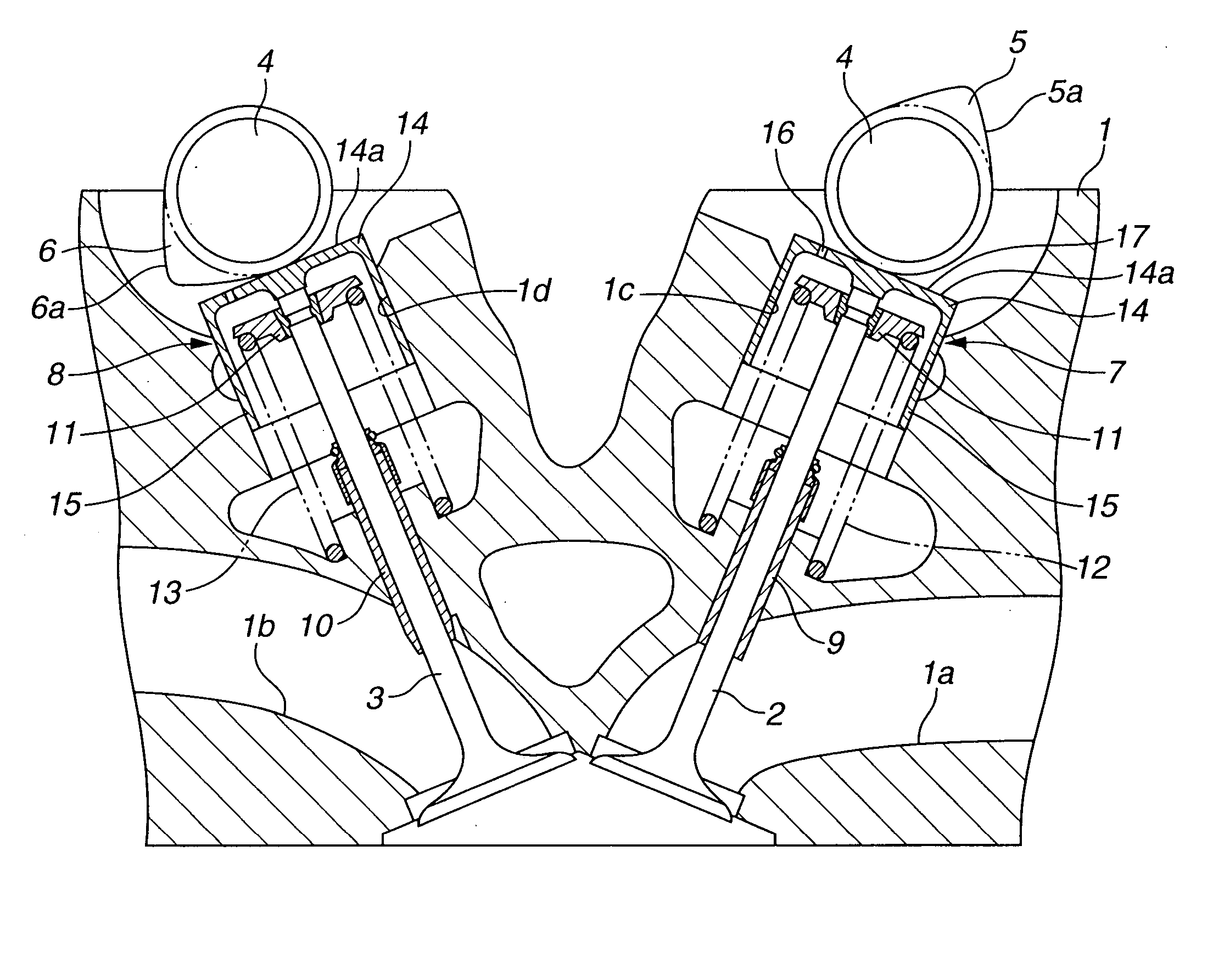

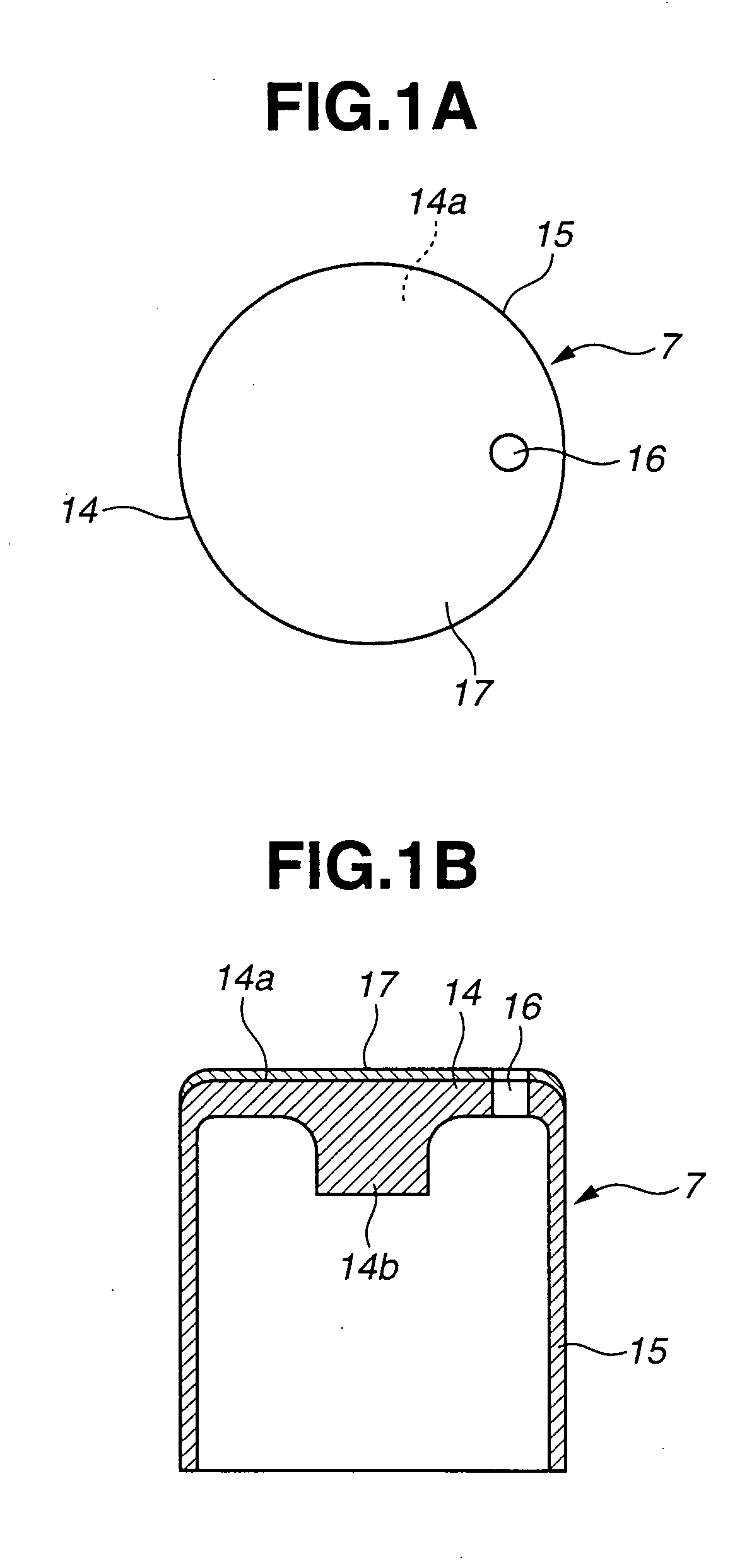

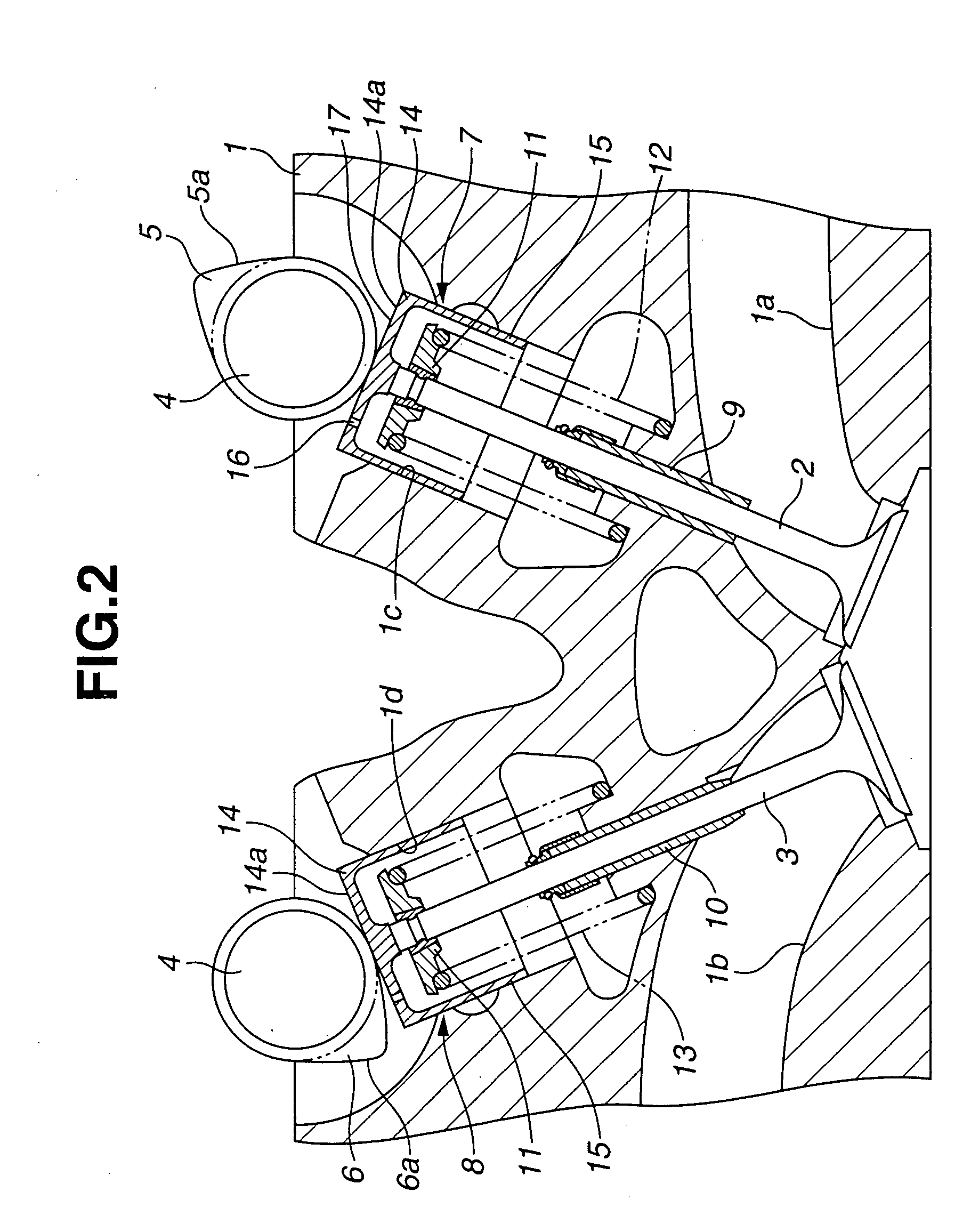

[0024] A preferred embodiment of the slide member and the method for producing the slide member, according to the present invention, will be described in detail below by referring to the accompanying drawings. The slide member has a slide surface slidable relative to a counterpart under condition that a lubricating oil is supplied between the slide member and the counterpart. In the embodiment, the slide member is used as a valve lifter in an internal combustion engine, which has a slide surface slidable relative to a cam so as to open and close an engine valve of the internal combustion engine.

[0025] Referring now to FIG. 2, there is shown a valve operating apparatus of an internal combustion engine in which the embodiment of the valve lifter according to the present invention is used. The valve operating apparatus includes intake valve 2 and exhaust valve 3 operative to open and close combustion chamber-side open ends of intake port 1a and exhaust port 1b, respectively, which are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com