Method and apparatus for spreading aggregate and road building materials related to vehicle speed

a technology of aggregate and road building materials, applied in the direction of roads, roads maintainence, roadways, etc., can solve the problems of inaccuracy in the distribution of materials, and high labor cost component when manual input is employed, so as to reduce human labor, automatic and controlled delivery of construction materials, and accurately spread granular materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will now be described in more detail according to a preferred but non limiting embodiment and with reference to the accompanying illustrations; wherein,

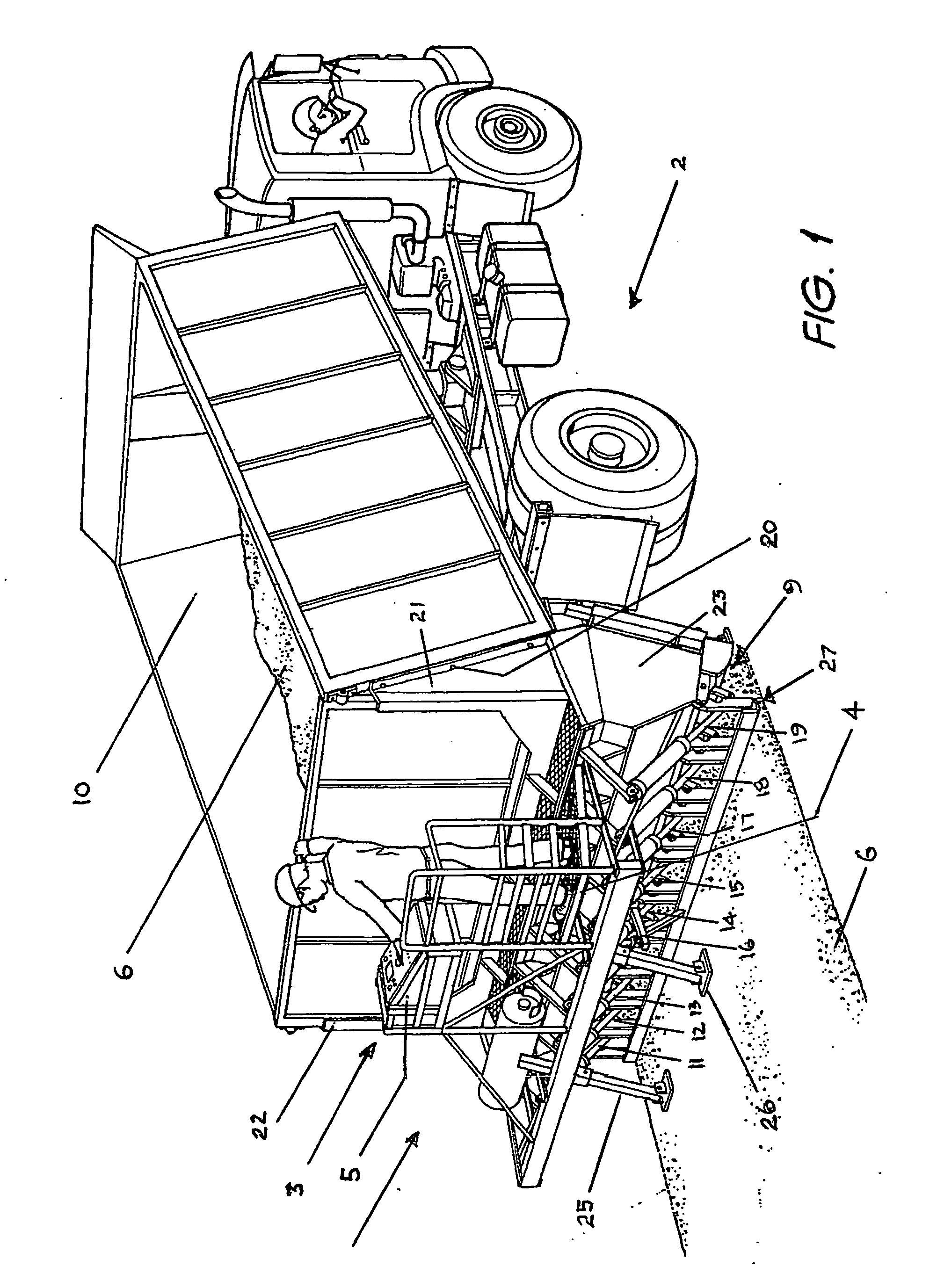

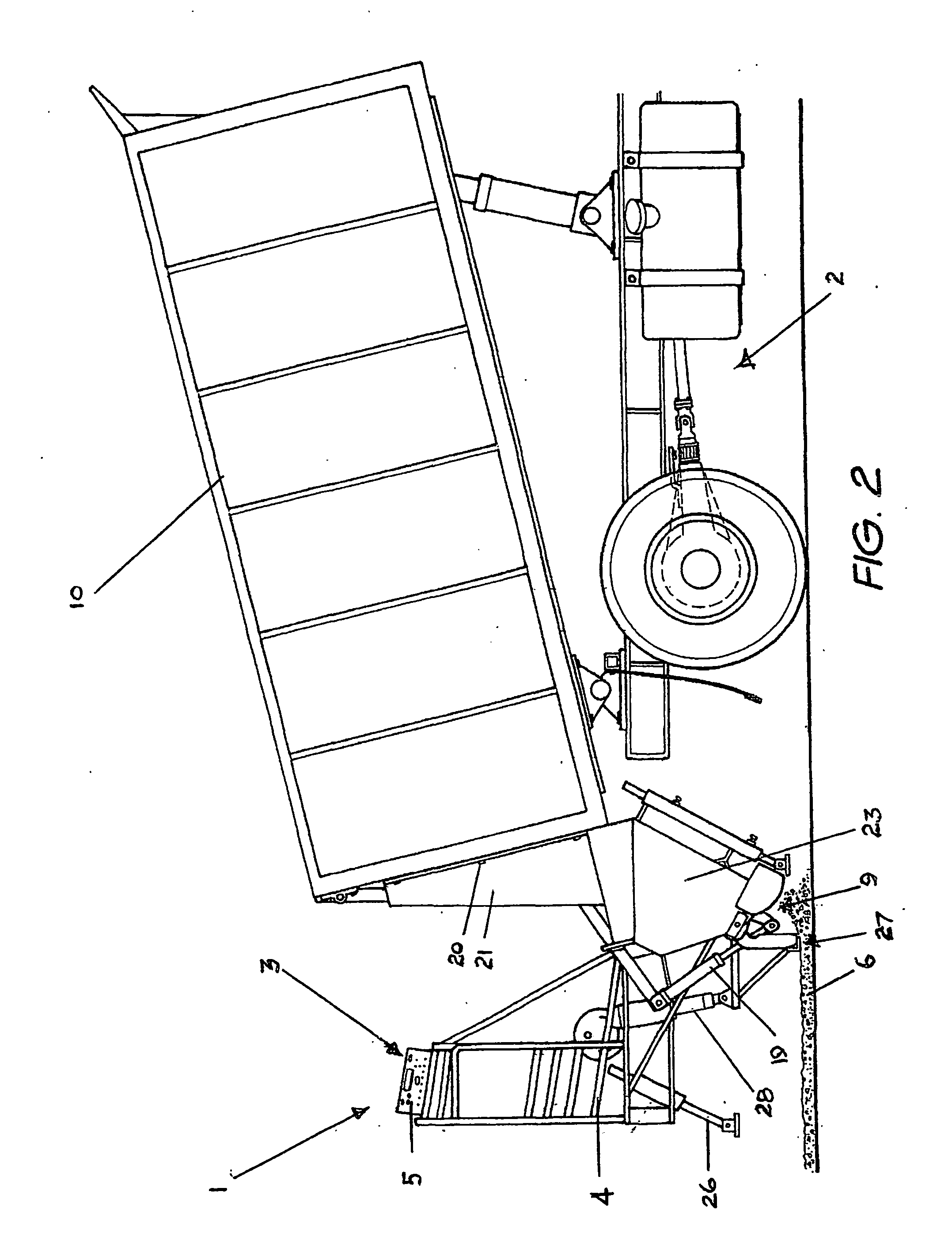

[0062]FIG. 1: shows a perspective view of a spreader assembly and control console according to one embodiment of the invention;

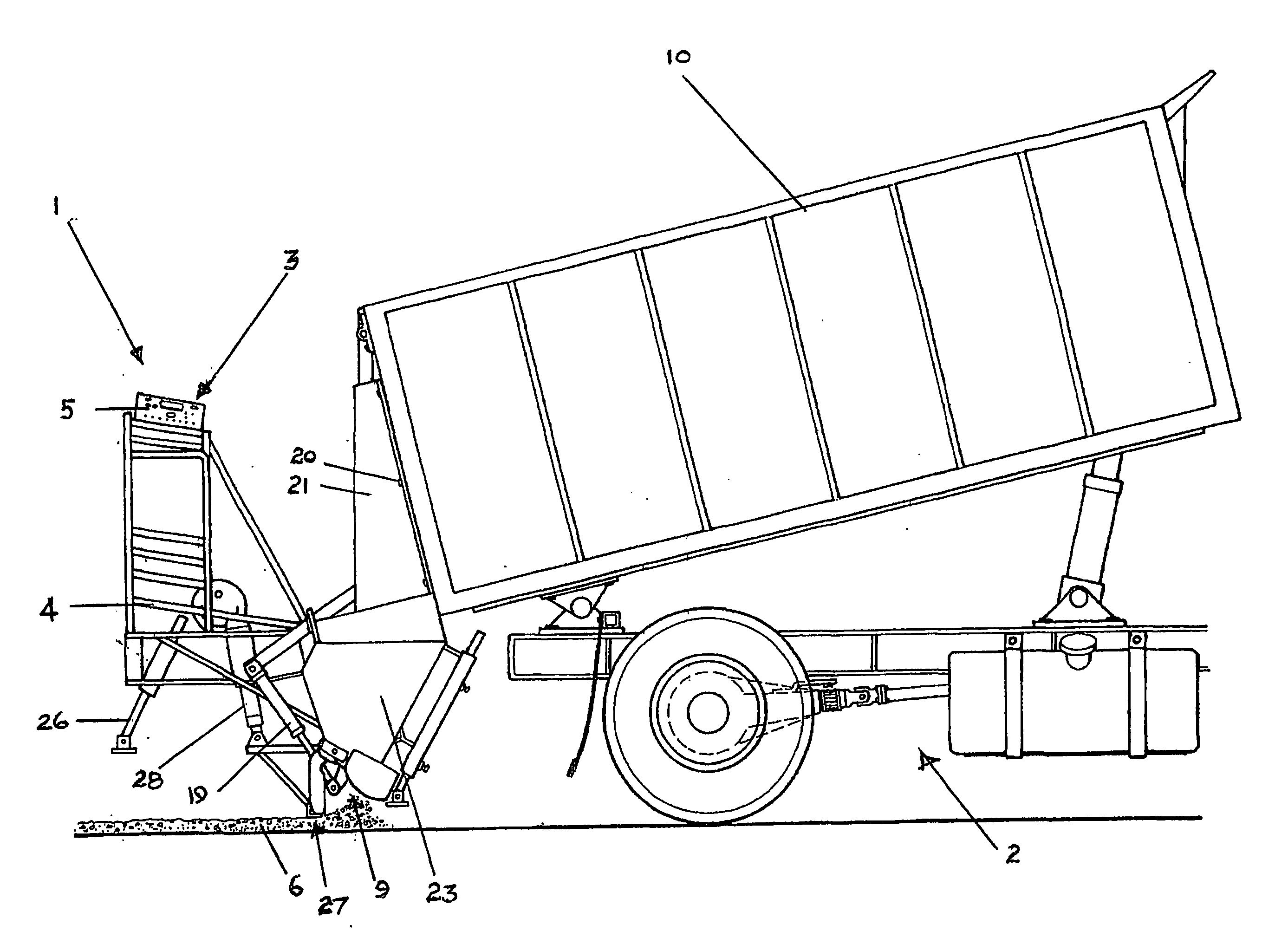

[0063]FIG. 2 shows a side elevation of the spreader assembly and control console of FIG. 1.

[0064]FIG. 3 shows a side elevation of the spreader with control console removed and with aggregate delivery gate closed

[0065]FIG. 4 shows the spreader of FIG. 3 with aggregate delivery gate partially open.

[0066]FIG. 5 shows the spreader of FIG. 4 with aggregate delivery gate fully open.

[0067]FIG. 6 shows the spreader of FIG. 1 with hopper detached from a vehicle.

[0068]FIG. 7 shows a schematic layout of control system elements according to a preferred embodiment

[0069]FIG. 8 shows a flow diagram of a typical operation of the control system of a computerised spreader box

[0070] The inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com