Eddy current sensing of metal removal for chemical mechanical polishing

a technology of electromagnetic sensing and metal removal, applied in the direction of lapping machines, manufacturing tools, instruments, etc., can solve the problems of reducing the throughput of the cmp apparatus, affecting the yield of the substrate, and affecting the use of the substrate, so as to improve yield and throughput, stop the process of polishing, and reduce the overpolishing and underpolishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

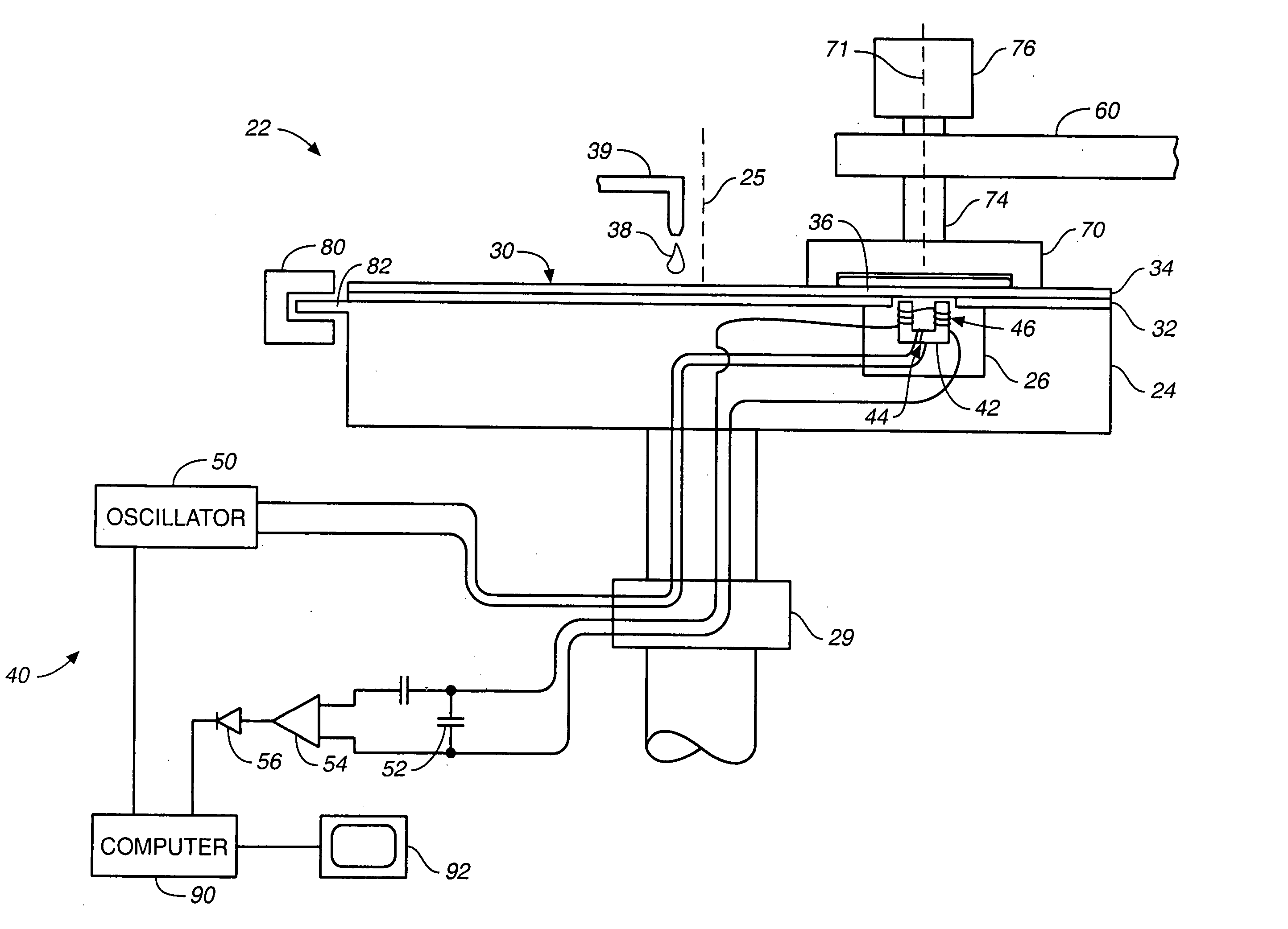

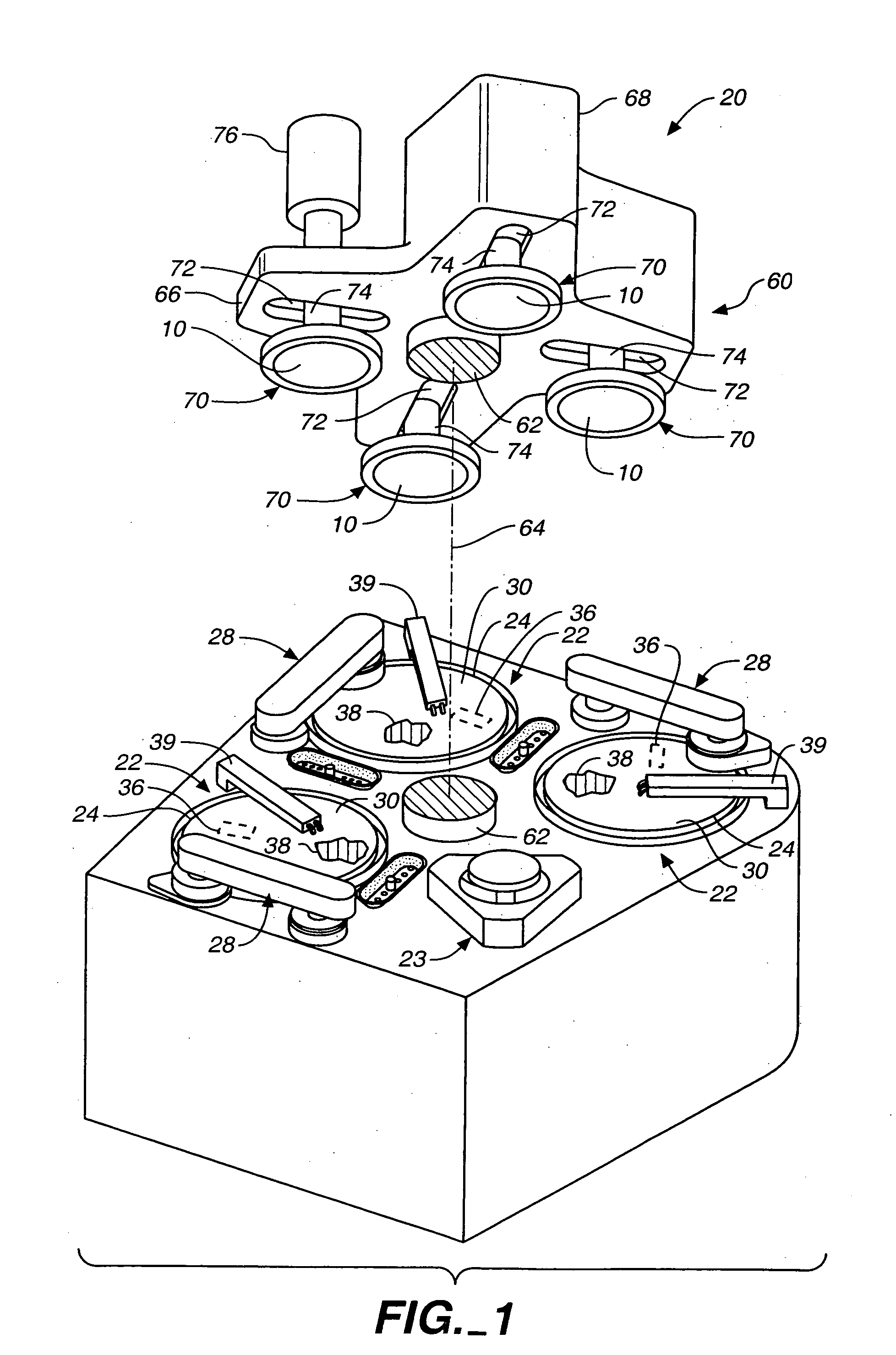

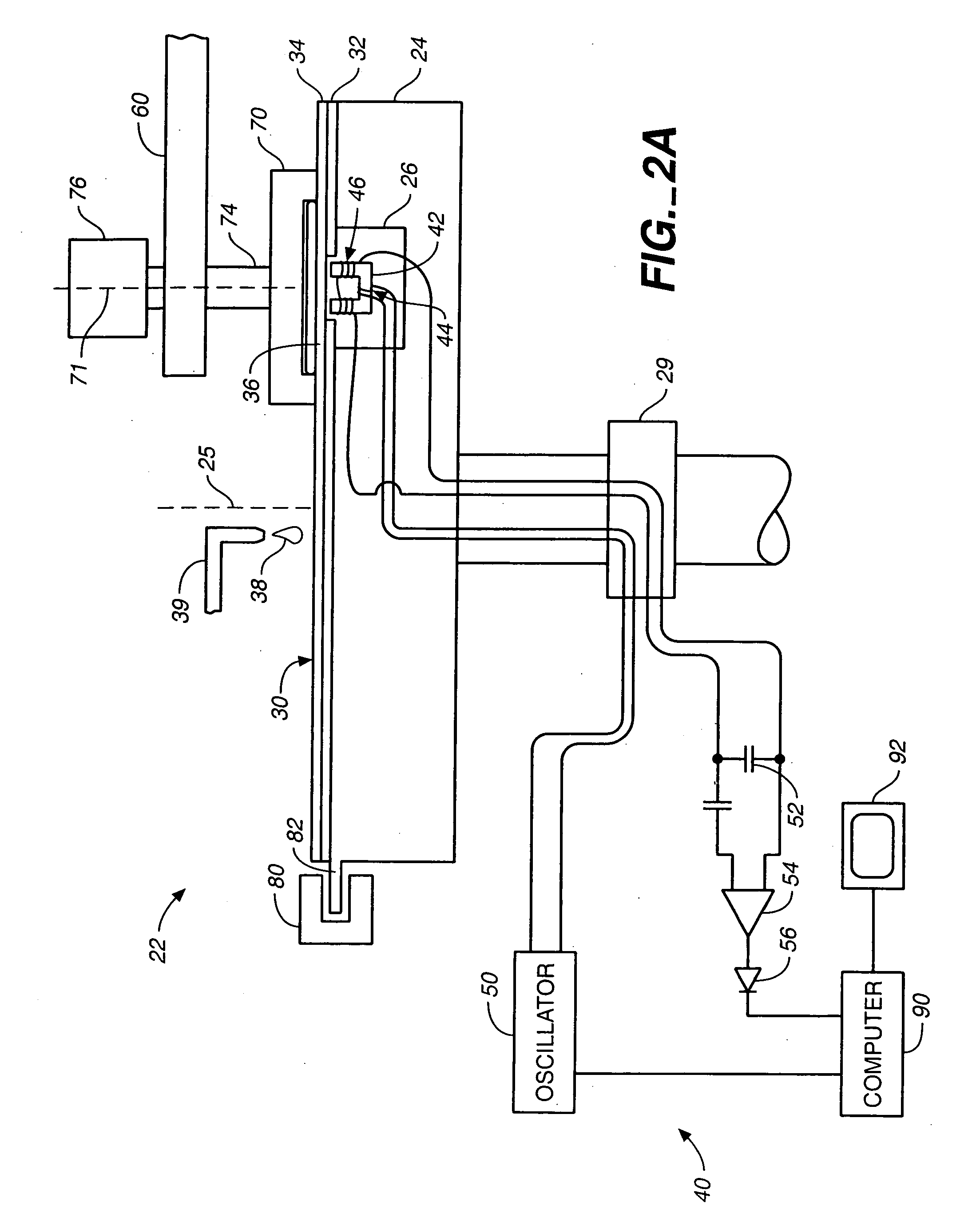

[0032] Referring to FIGS. 1 and 2A, one or more substrates 10 can be polished by a CMP apparatus 20. A description of a similar polishing apparatus 20 can be found in U.S. Pat. No. 5,738,574, the entire disclosure of which is incorporated herein by reference. Polishing apparatus 20 includes a series of polishing stations 22 and a transfer station 23. Transfer station 23 transfers the substrates between the carrier heads and a loading apparatus.

[0033] Each polishing station includes a rotatable platen 24 on which is placed a polishing pad 30. The first and second stations can include a two-layer polishing pad with a hard durable outer surface or a fixed-abrasive pad with embedded abrasive particles. The final polishing station can include a relatively soft pad. Each polishing station can also include a pad conditioner apparatus 28 to maintain the condition of the polishing pad so that it will effectively polish substrates.

[0034] A two-layer polishing pad 30 typically has a backing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eddy currents | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com