Viscous fluid metering device

a viscous fluid and metering device technology, applied in liquid/fluent solid measurement, volume measurement, open container, etc., can solve the problems of hot applied sealant mix solids coming out of suspension, and the replacement of a nozzle can significantly affect machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

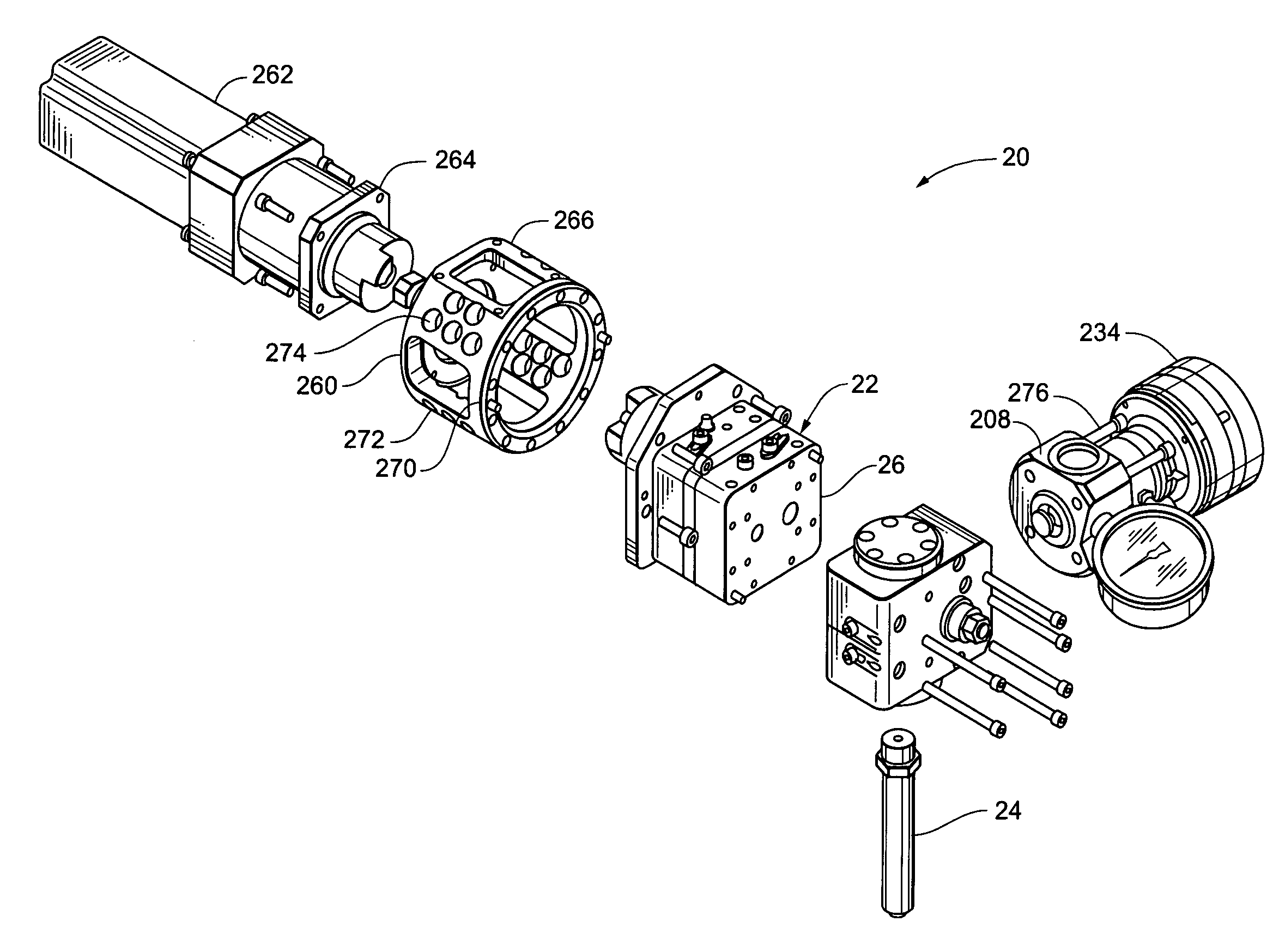

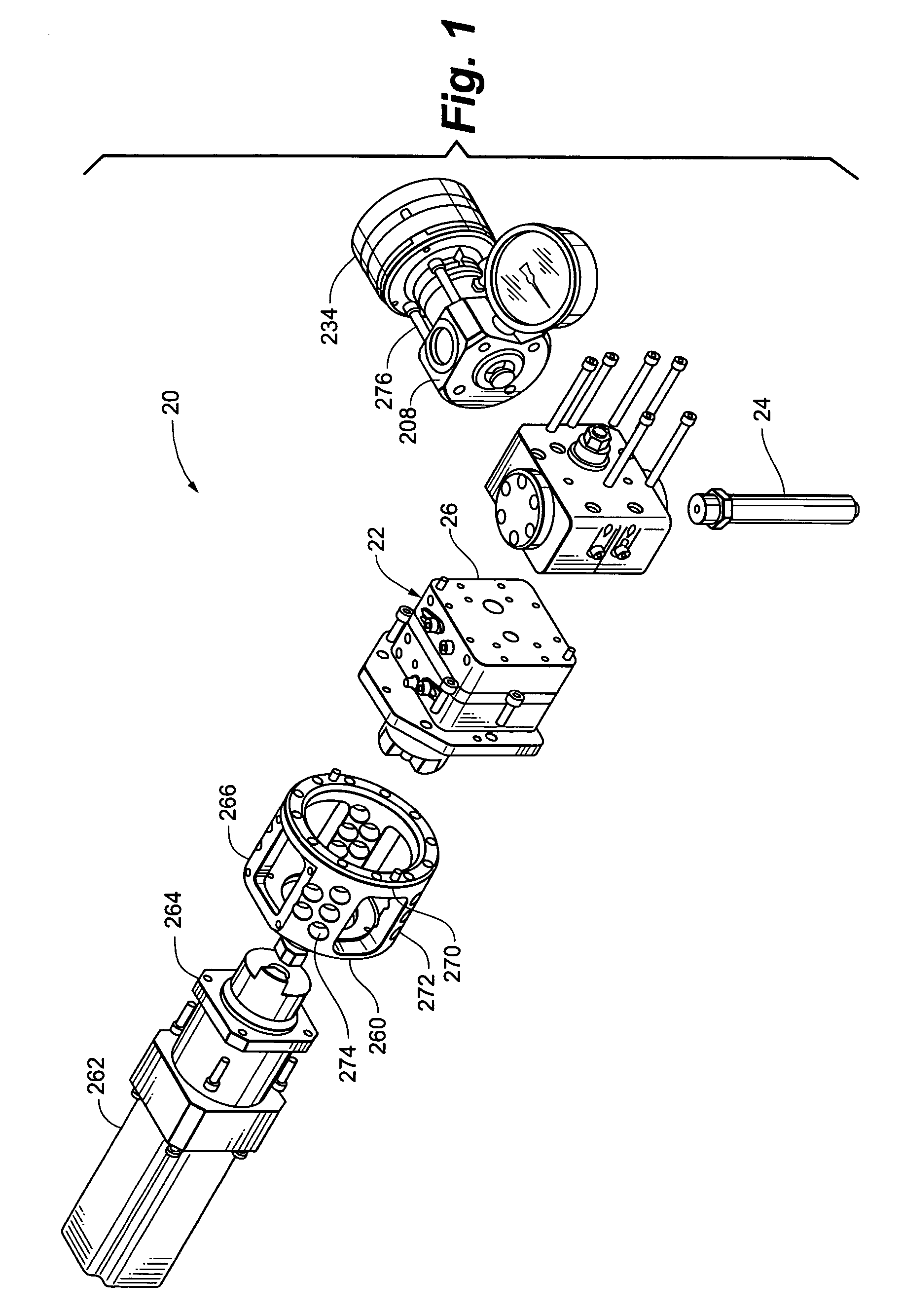

[0053] Referring to FIGS. 1, viscous liquid dispenser 20 generally includes a metering device 22 and a nozzle assembly 24. Metering device 22 is in fluid communication with nozzle assembly 24 so that viscous liquid material that leaves metering device 22 flows to and, ultimately through nozzle assembly 24. The metering device 22 generally includes metering device body 26 and gear assembly 28. Gear assembly 28 is enclosed within and surrounded by metering device body 26.

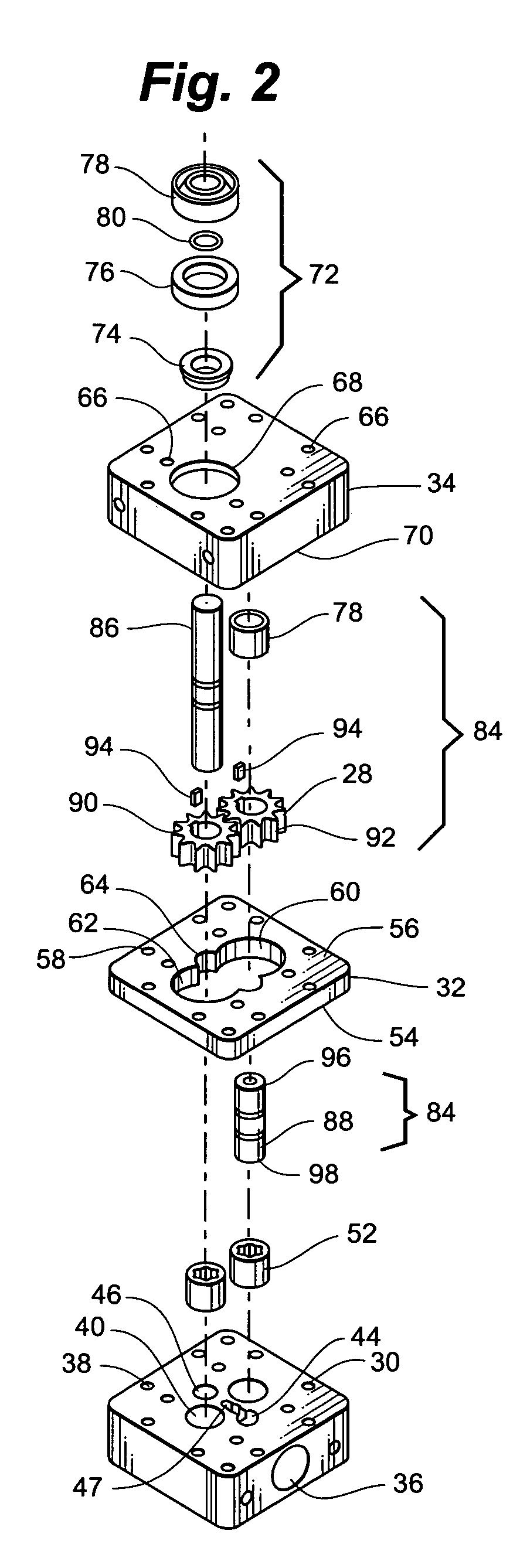

[0054] Referring to FIGS. 2, 20 and 21, metering device body 26 is generally divided into three major subcomponents, port plate 30, center plate 32 and drive plate 34. Each of port plate 30, center plate 32 and drive plate 34 have a plurality of passageways, apertures and cavities machined or otherwise formed in them.

[0055] Port plate 30 defines inlet 36, a plurality of boltholes 38 and bearing cavities 40. Inlet 36 leads to inlet passage 42 which terminates at interior inlet 44. Thus, inlet passage 42 provides for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com