Fan impeller and fan motor

a technology of impeller and fan, which is applied in the direction of piston pumps, marine propulsion, vessel construction, etc., can solve the problems of reducing the airflow volume of the fan and lowering the cooling efficiency below the inherent performance of the fan motor, and achieves the effect of maximum cooling efficiency and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

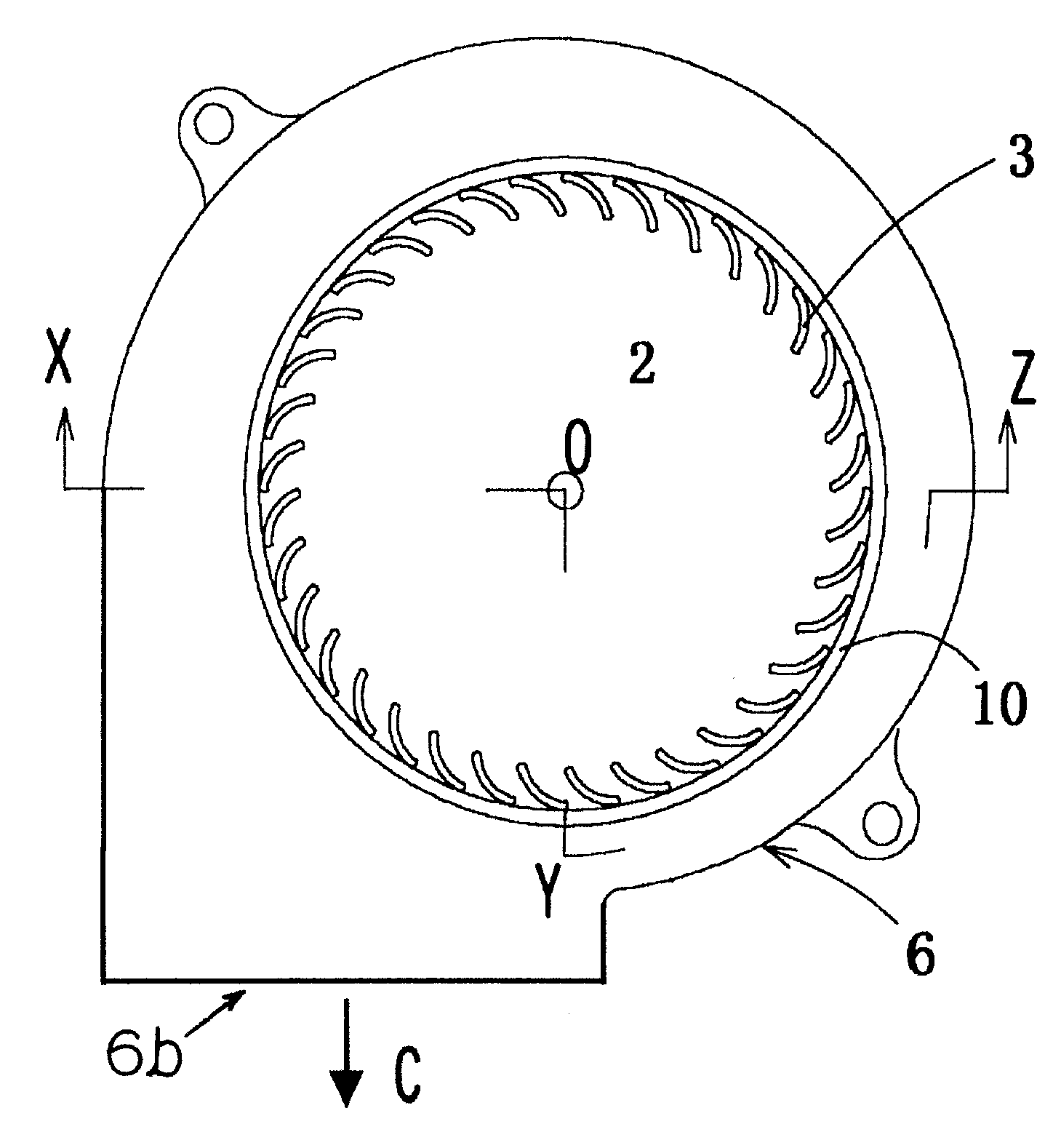

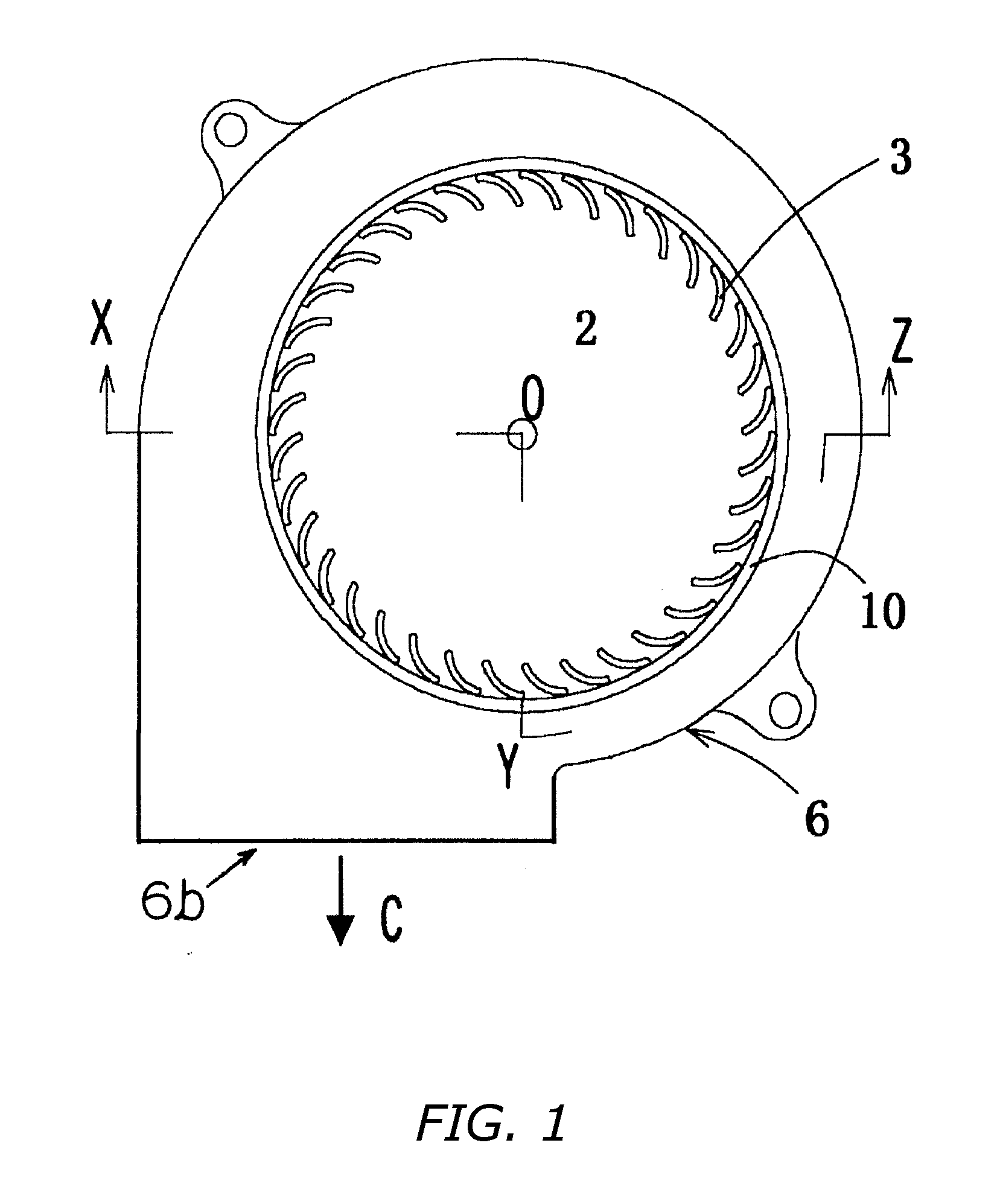

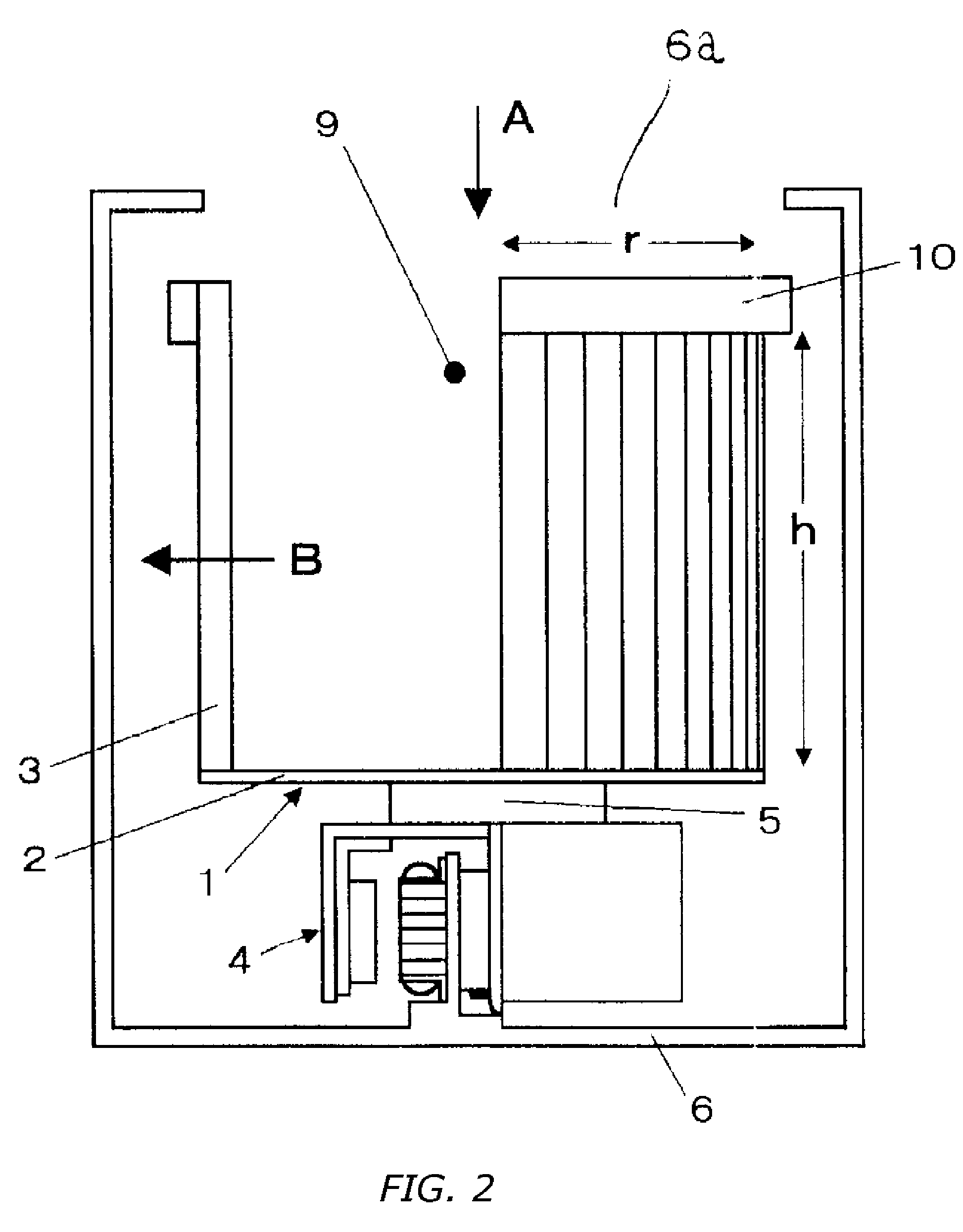

[0029] Reference is made to FIG. 1, which is a plan view of a centrifugal fan motor according to an embodiment of the present invention, and to FIG. 2, which is a vertical cross section, taken along the line X-O-Y-Z in FIG. 1. The vertical direction in FIG. 2 corresponds to the orientation of the rotational axis of the centrifugal fan motor. Though upper and lower sides are defined according to FIG. 2 in the following explanation, the definitions are for convenience of explanation and are not meant to imply restrictions on the actual attachment posture of the fan motor.

[0030] This fan motor includes an impeller component 1, a motor component 4 and a housing 6. The impeller component 1 and the motor component 4 are disposed axially stacked and connected to each other, and these interconnected components are contained in the housing 6. The rotational axis of this centrifugal fan motor is indicated by O in FIG. 1.

[0031] Reference is now made to FIG. 3, which shows the impeller compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com