Image forming apparatus, image forming method and data control device

a technology of image forming apparatus and data control device, which is applied in the direction of electrographic process apparatus, instruments, printing, etc., can solve the problems of color registration offset, skew where, and image quality degradation, and achieve high quality, high accuracy, and increase the accuracy of color registration offset correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

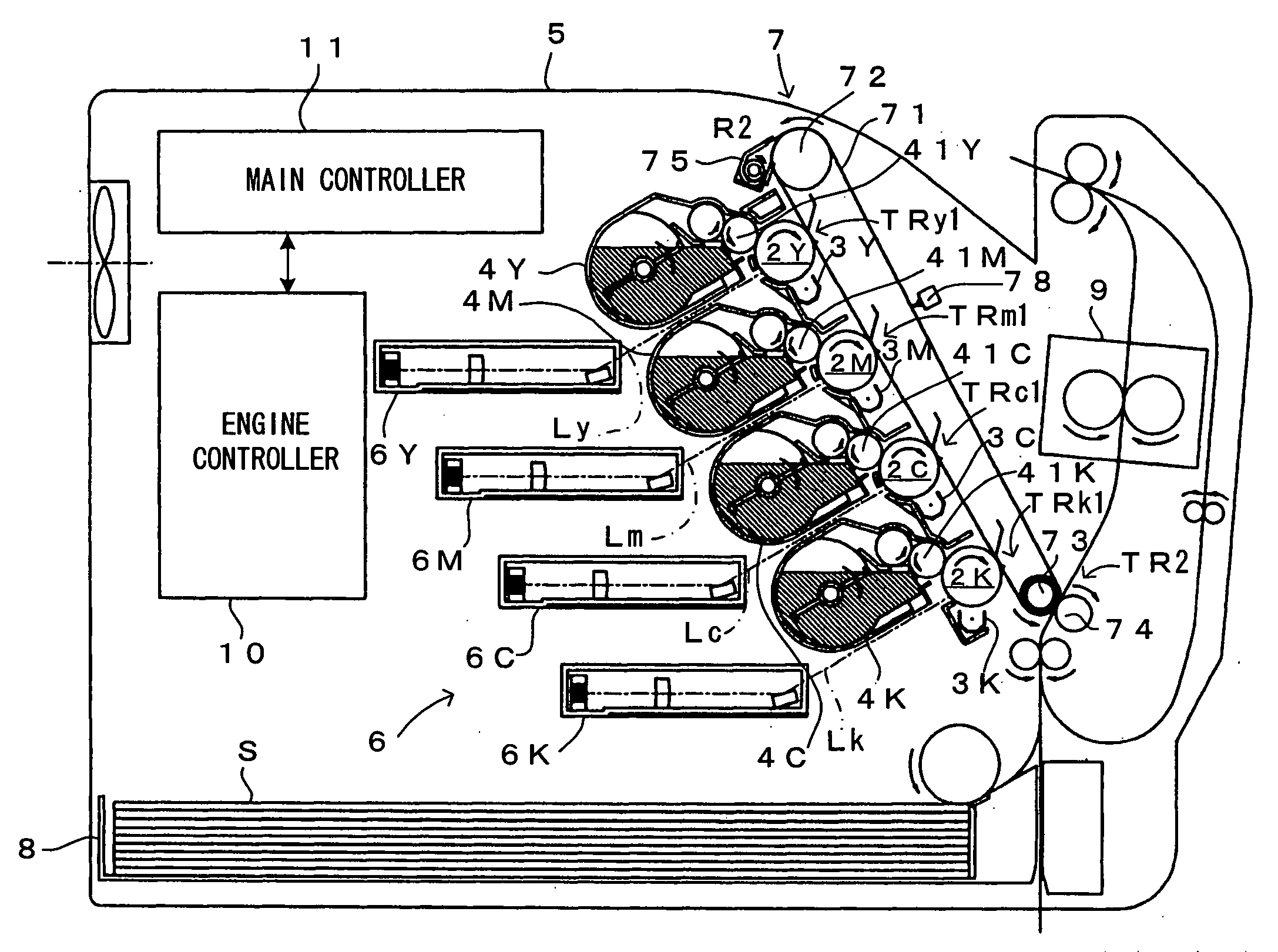

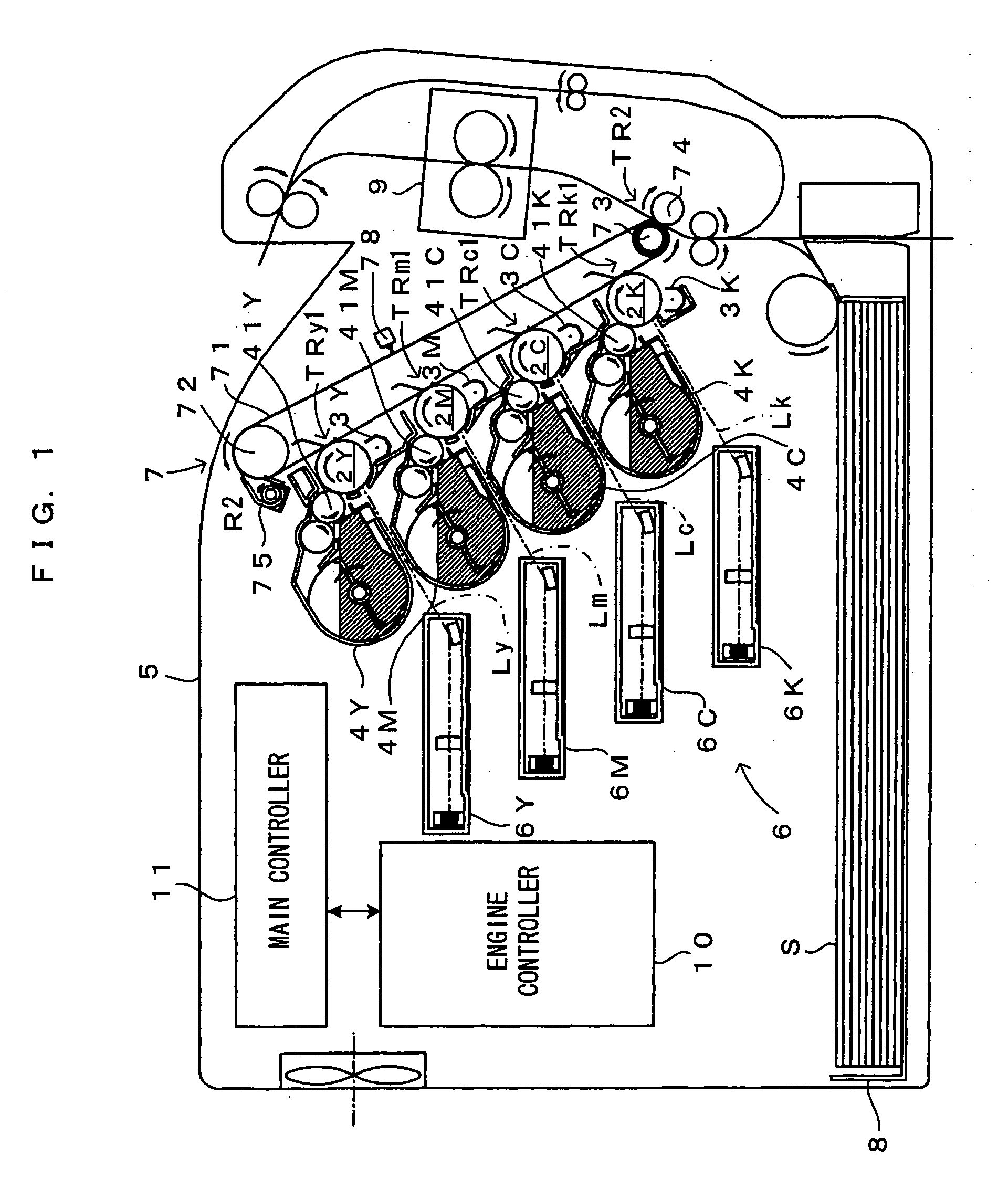

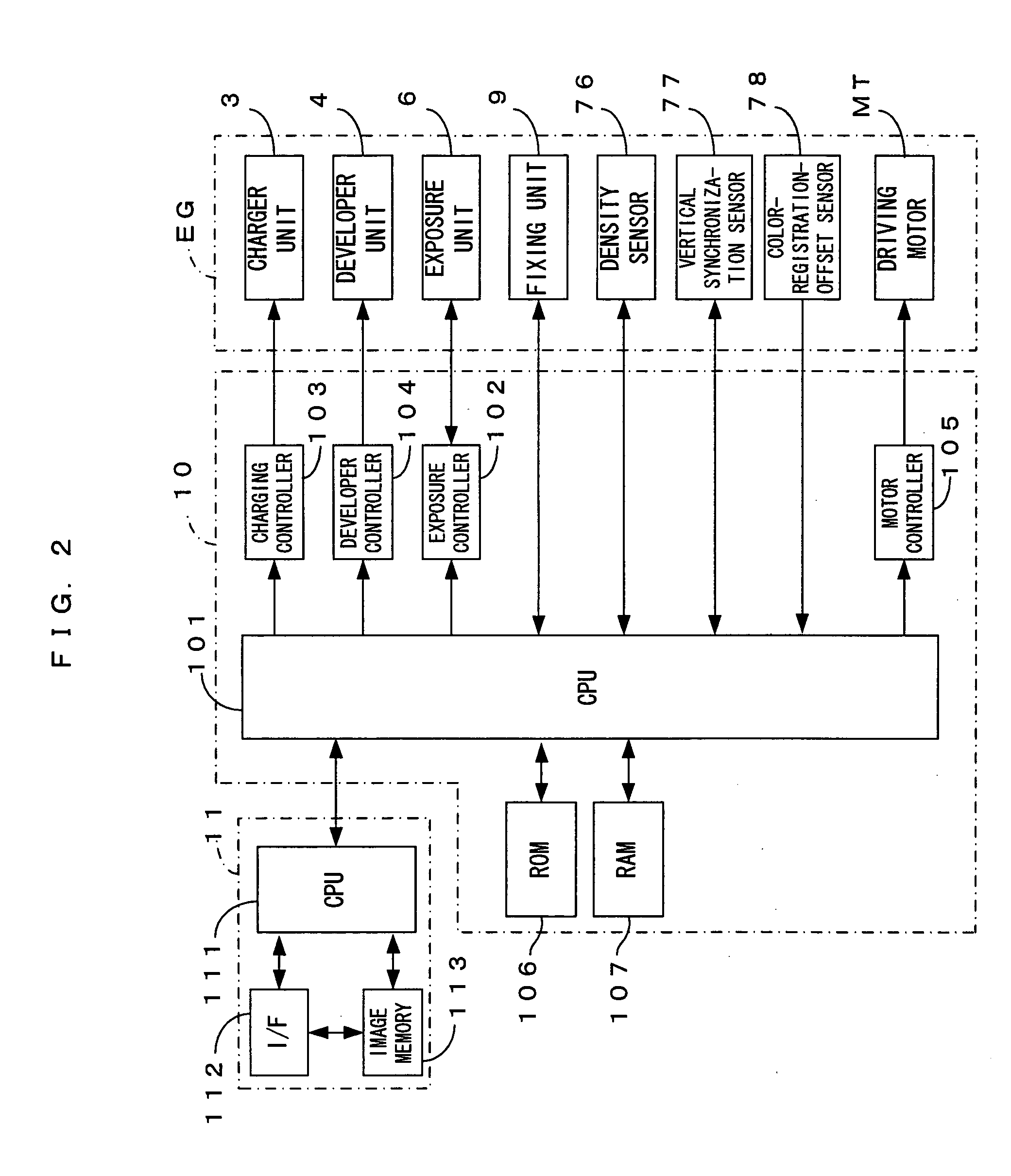

[0078]FIG. 1 is a diagram showing an image forming apparatus according to a first embodiment of the invention. FIG. 2 is a block diagram showing an electrical structure of the image forming apparatus shown in FIG. 1. This image forming apparatus is a so-called tandem color printer, wherein photosensitive members 2Y, 2M, 2C, 2K for four colors of yellow (Y), magenta (M), cyan (C) and black (K), as latent image carriers, are juxtaposed to each other in an apparatus body 5. The apparatus serves to form a full color image by superimposing toner images on the individual photosensitive members 2Y, 2M, 2C, 2K, or to form a monochromatic image using only the toner image of black (K). The image forming apparatus operates as follows. When an external apparatus such as a host computer applies a print command to a main controller 11 in response to a request from a user wanting to form an image, a CPU 111 of the main controller 11 sends a print command, based on which an engine controller 10 con...

second embodiment

[0109]FIG. 9 is a block diagram showing an electric structure of an image forming apparatus according to a second embodiment of the invention. It is noted that the apparatus of the second embodiment is structured the same way as the first embodiment and hence, the same components as those of the first embodiment are represented by the same reference characters, respectively, the description of which is dispensed with. As shown in FIG. 9, the second embodiment further includes an FRAM (ferroelectric memory) 108 for storing information related to status of use of the individual parts of the engine.

[0110]FIG. 10 is a main scanning cross sectional view showing a structure of the exposure unit which is disposed in the image forming apparatus according to a second embodiment of the invention. FIG. 11 is a diagram showing a scan region of the light beam in the exposure unit shown in FIG. 10. FIG. 12 is a diagram showing signal processing blocks of the image forming apparatus according to ...

third embodiment

[0133] In the second embodiment described above, the scanning direction of the latent-image forming light beam is selectively switched based on the skew information which is set in advance. However, an adjustment toner image (registration mark) for adjusting the latent-image forming position may be formed, and may obtain an amount of offset of the linear latent image relative to a predetermined reference line (amount of color registration offset) by detecting the adjustment toner image by means of the color-registration-offset sensor 78, as the “information related to latent-image forming position on latent image carrier” of the invention. Thus, in a third embodiment, the color-registration-offset sensor 78 functions as an “information detector” of the invention. Since the apparatus is essentially structured the same way as that of the second embodiment, the description of this embodiment will focus on a switching method. In this regard, the same applies to fourth and fifth embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com