Tent and its components

a technology of tents and components, applied in tents/canopies, building types, constructions, etc., can solve the problems of affecting the quality of tents, affecting the appearance of tents, so as to prevent or at least reduce the effect of frozen condensation or fros

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

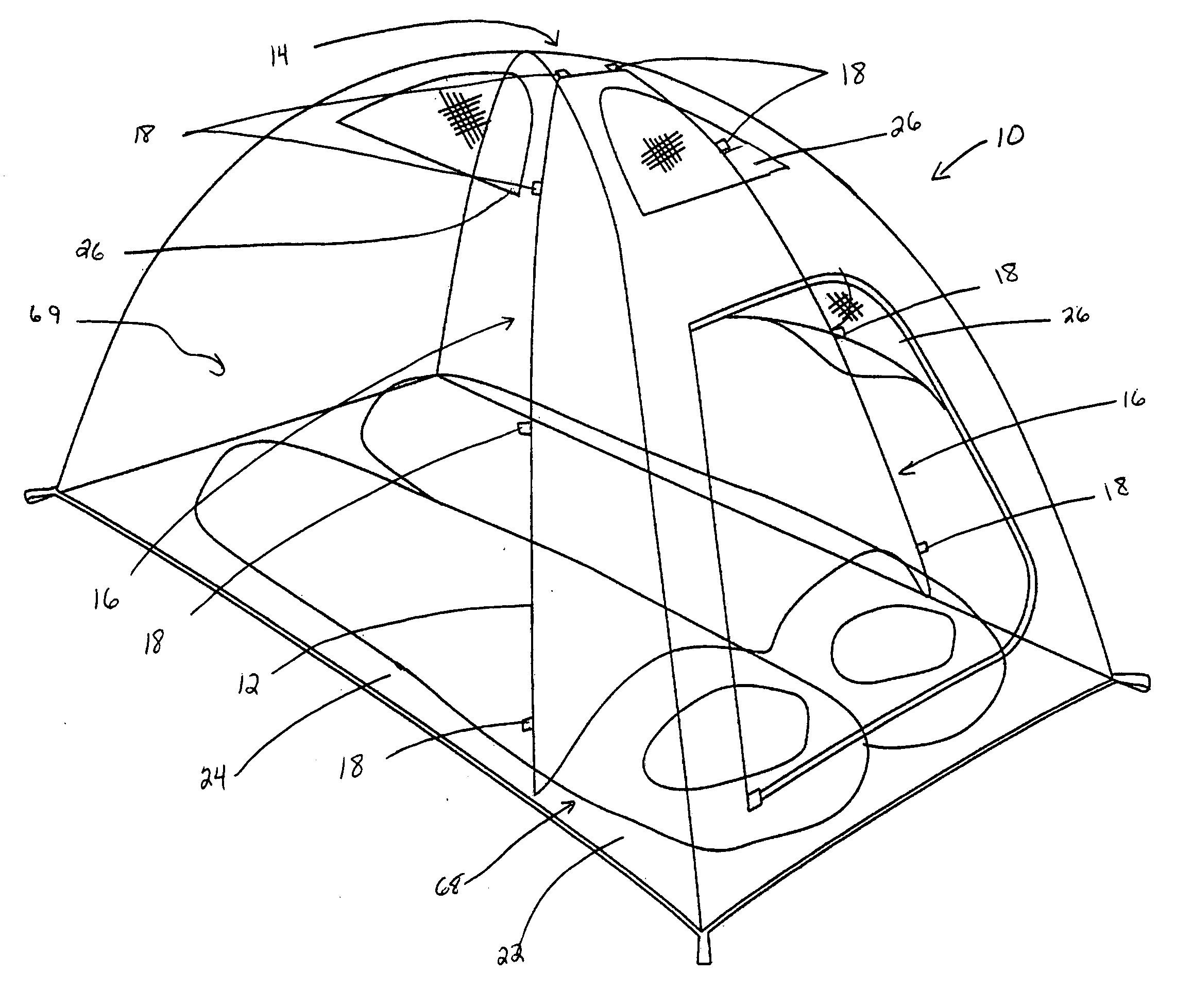

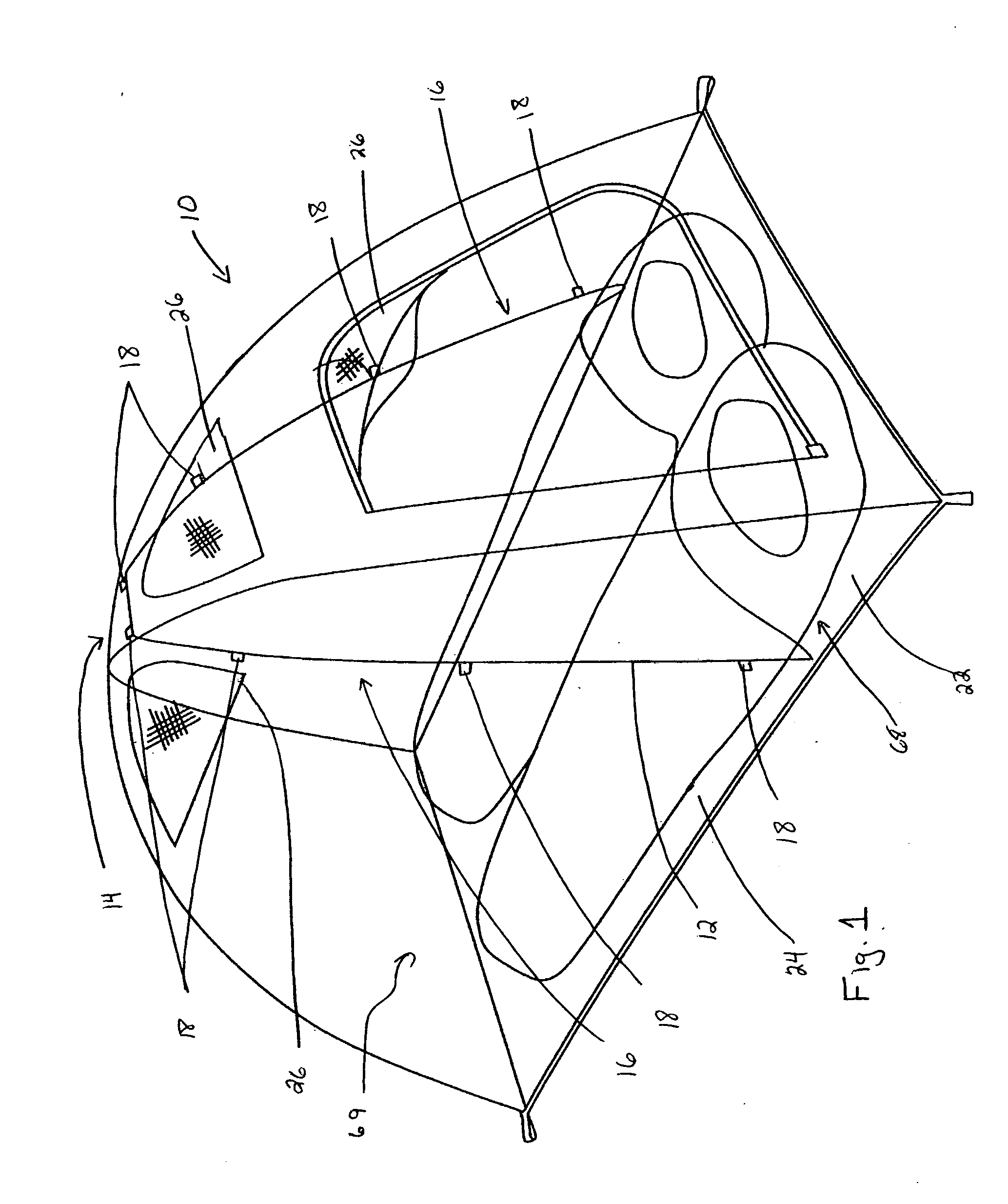

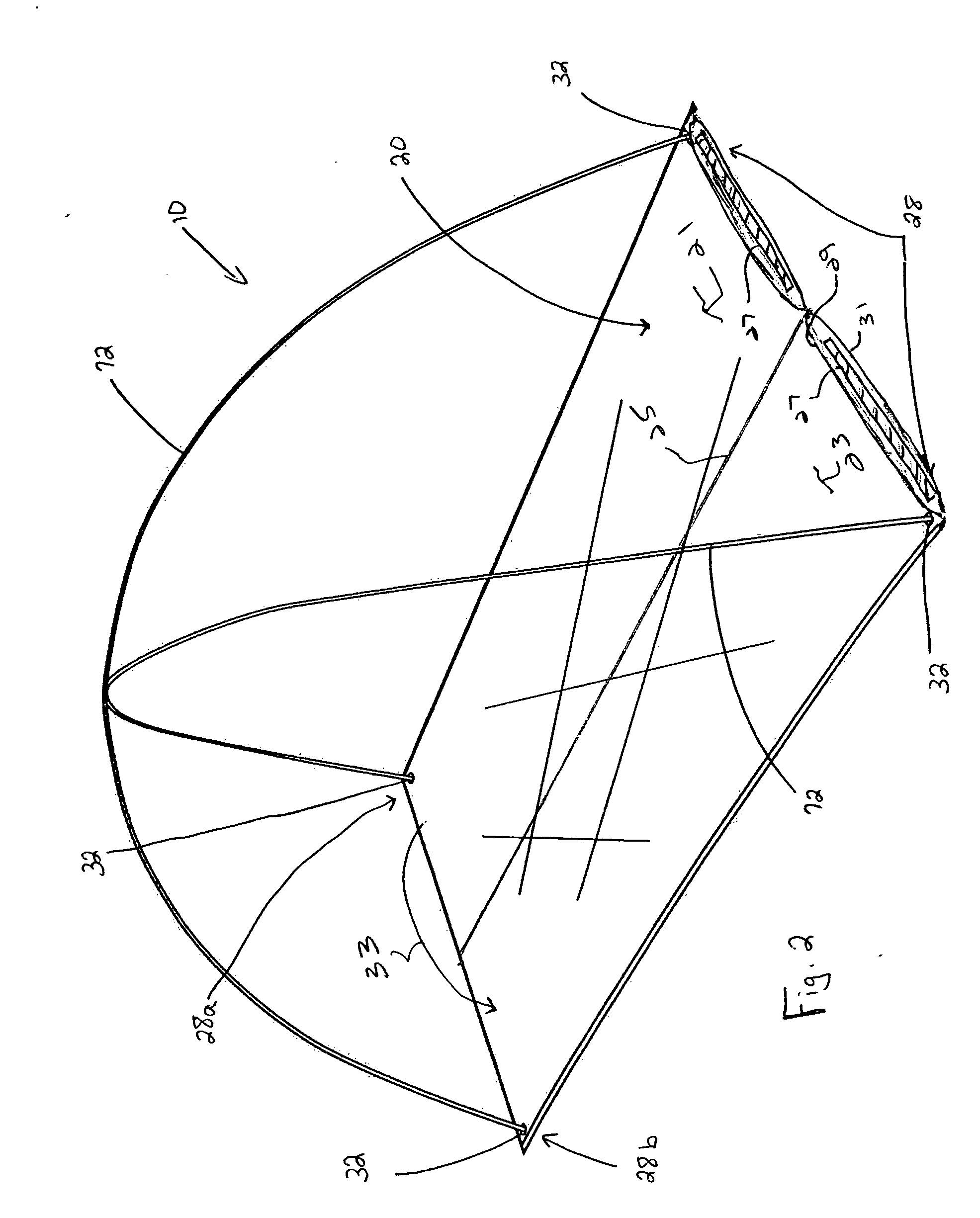

[0020] The present invention includes a tent 10, FIG. 1, having one or more of a condensation barrier or curtain 12, removable insulated floor 20, reinforced portions 30, retractable vestibule 40, pressure vents or vent cowlings 50, insulated walls 60, and a split outer door vent 70.

[0021] The condensation barrier 12 is operatively attached to inside surfaces of the tent 10, FIG. 1 in one or more regions. In the preferred embodiment, the condensation barrier 12 is made of very lightweight, thin material that does not readily absorb water and dries quickly in the sun. For example, the condensation barrier 12 may be a lightweight fabric such as a 40 denier polyester ripstop.

[0022] The condensation barrier 12 is attached to a top surface 14 and sides 16 of the tent 10. In one embodiment, the condensation barrier 12 is attached to the top surface 14 and the sides 15 with fasteners 18. In one embodiment, the fasteners 18 are hook & loop fasteners; however, other types of fasteners, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com