Multi-functional compact with storage receptacles

a multi-functional, compact technology, applied in the field of containers, can solve the problems of inability to achieve dual packaging methods, and achieve the effect of economic manufacture and greater ability to customize packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

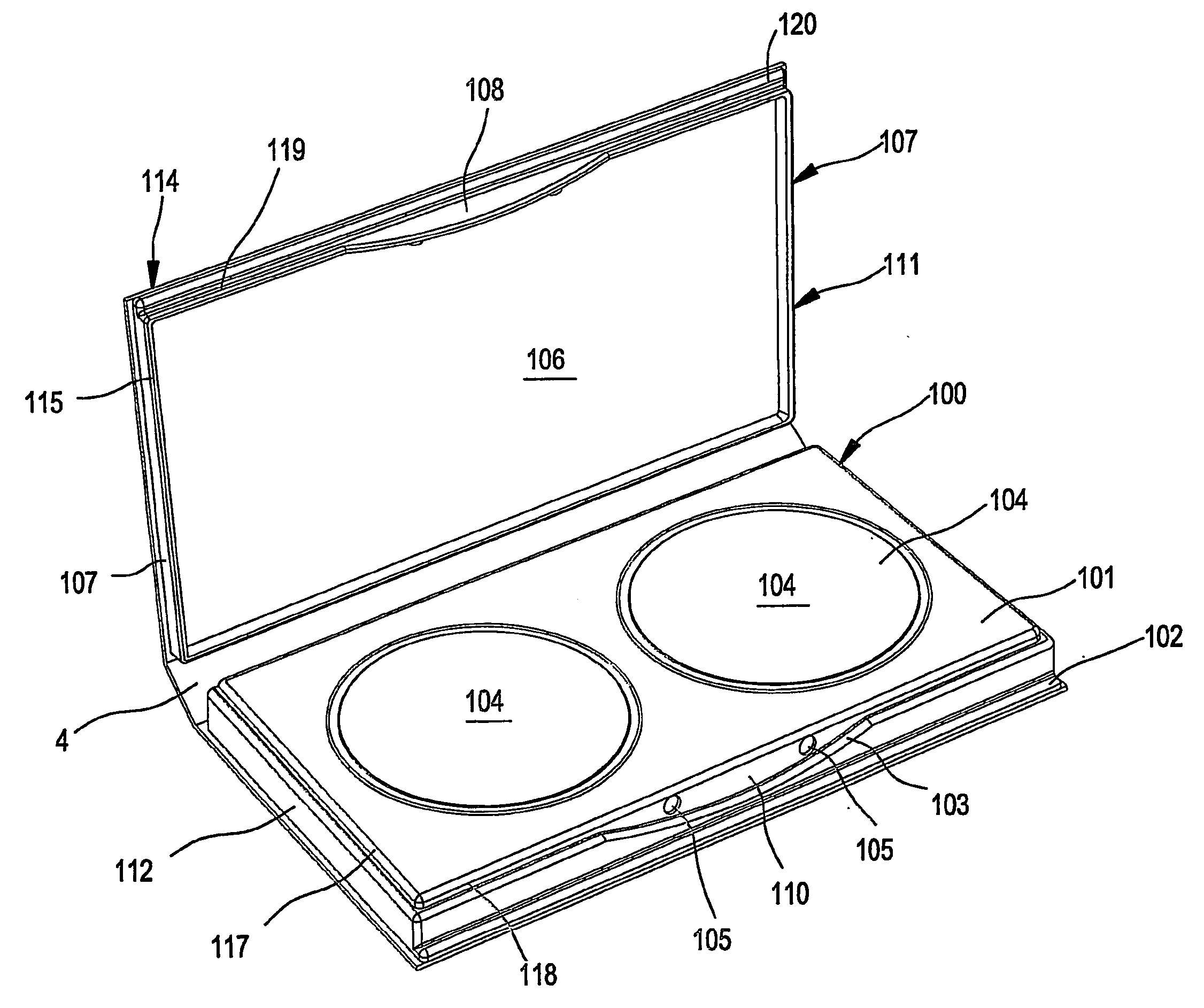

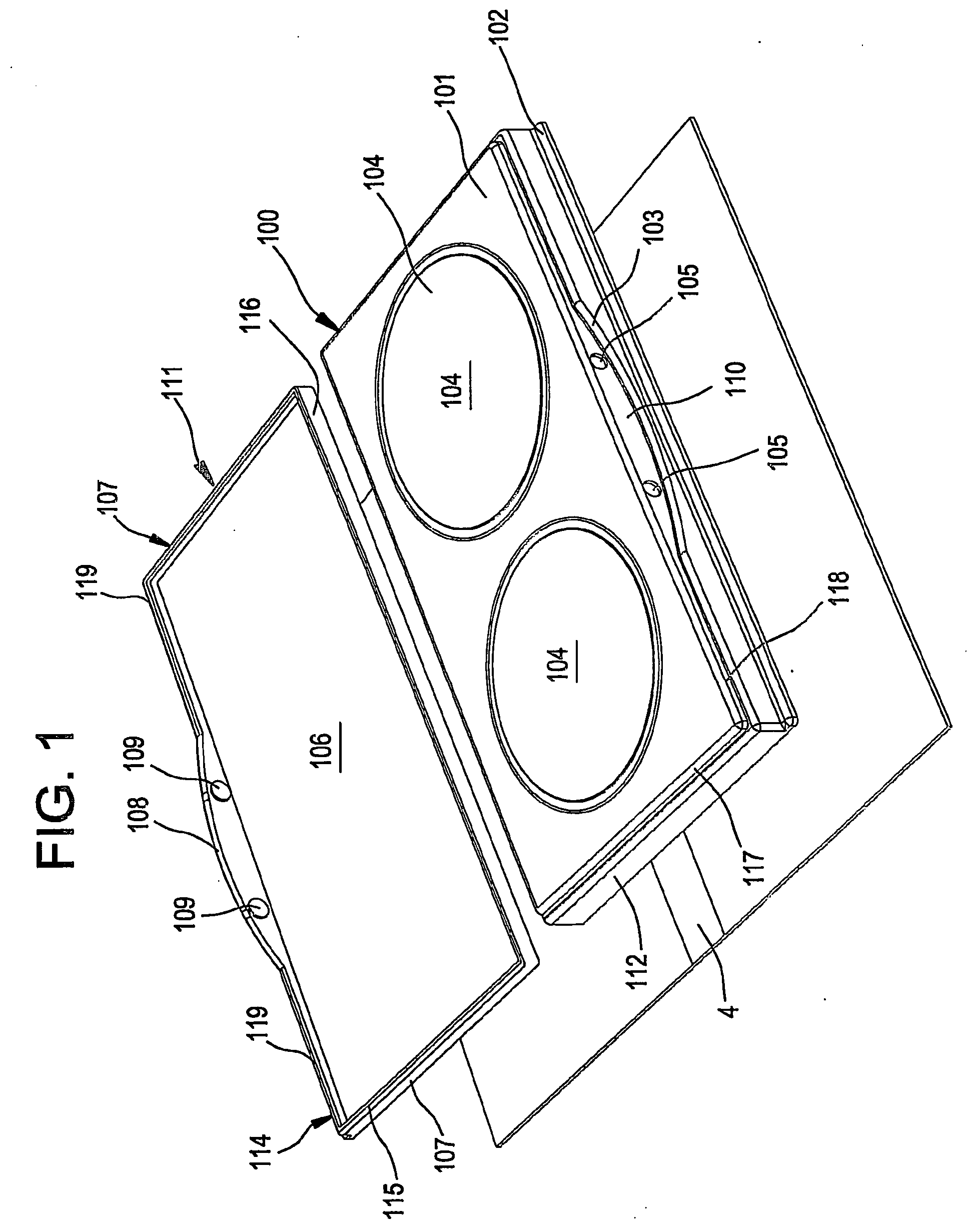

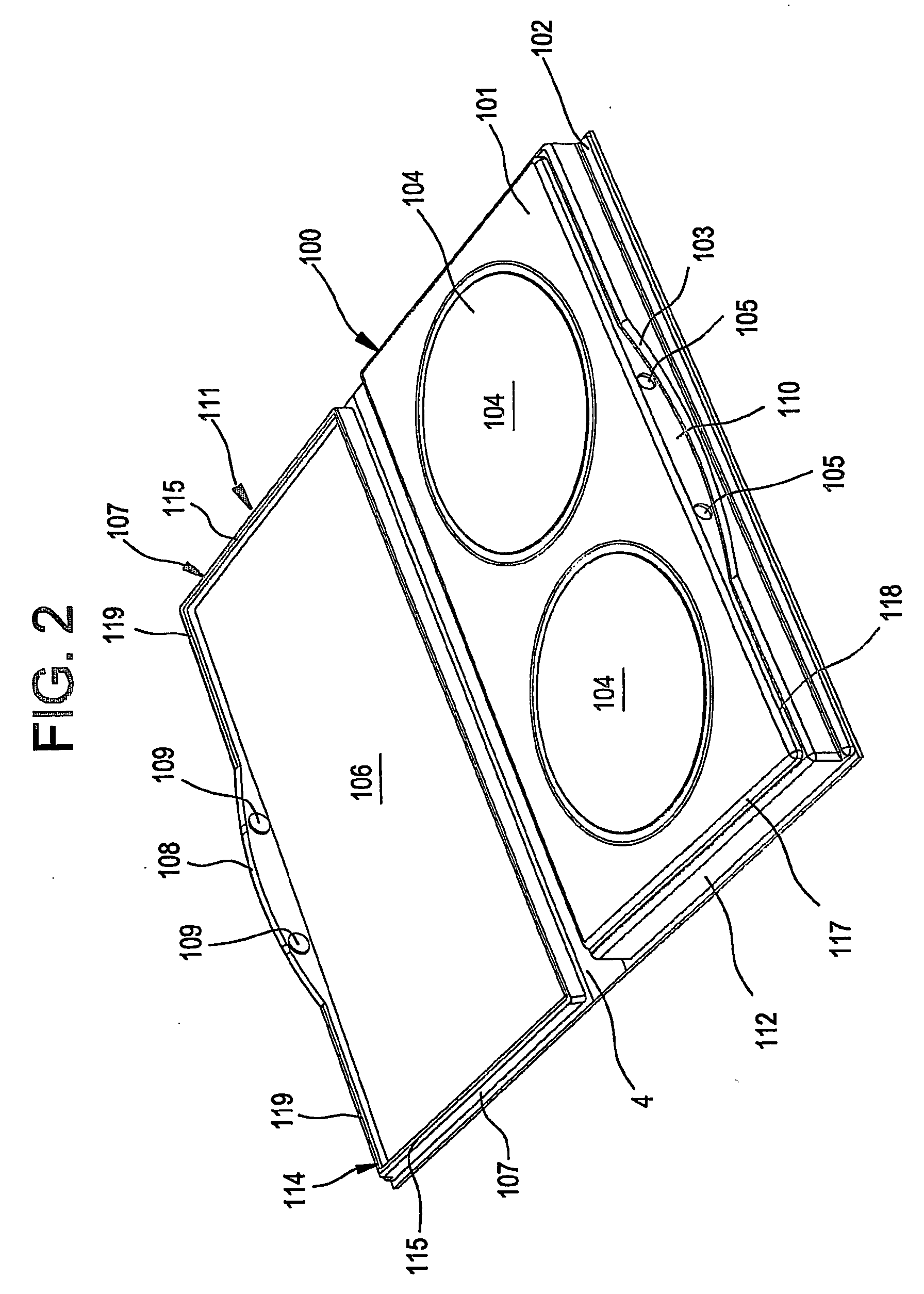

[0055] As shown in FIGS. 1-5, a multifunctional compact according to the invention comprises a first formed plastic tray 100, a second formed plastic tray 111, and an outer cover 1 formed of a paperboard substrate. The first formed plastic tray 100 includes a collar region 101 and receptacles 104 formed as depressions therein. The first formed plastic tray 100 includes upstanding side walls 112 and a front wall 113 formed perpendicularly to the side walls 112. The first formed plastic tray 101 additionally includes a beveled edge 117 that runs continuously along each of the side walls 112 and corresponds with a beveled edge 118 that extends along at least a portion of the front wall 113. Front wall 113 further has a recessed edge 103 thereof forming a recessed region 110 that provides an access area for a locking element, and to assist with opening the tray. Also included in the first formed plastic tray 101 is an extension 102 running along the entire length of the outer edge of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| shapes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com