High tensile strength carbon nanotube film and process for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

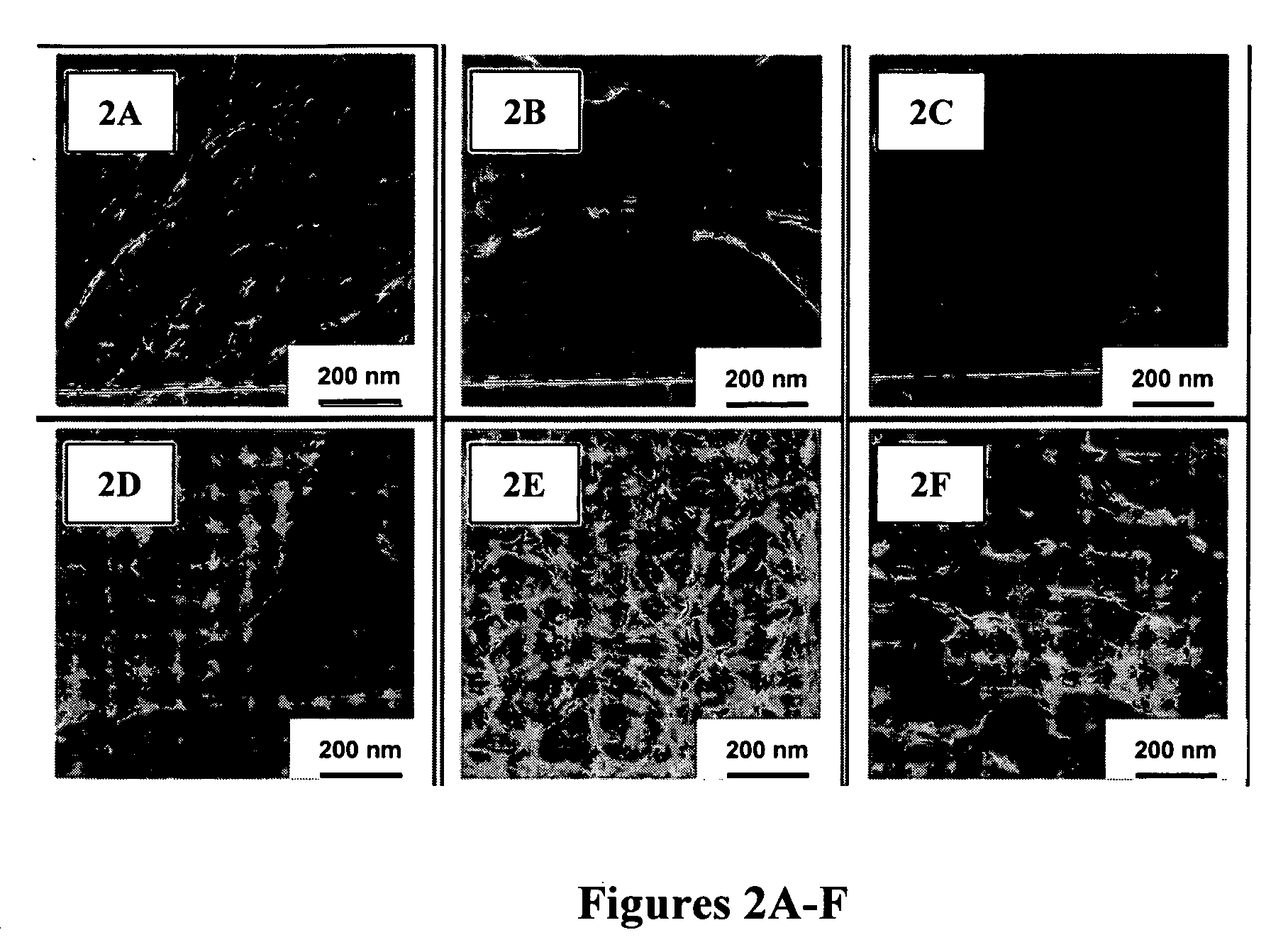

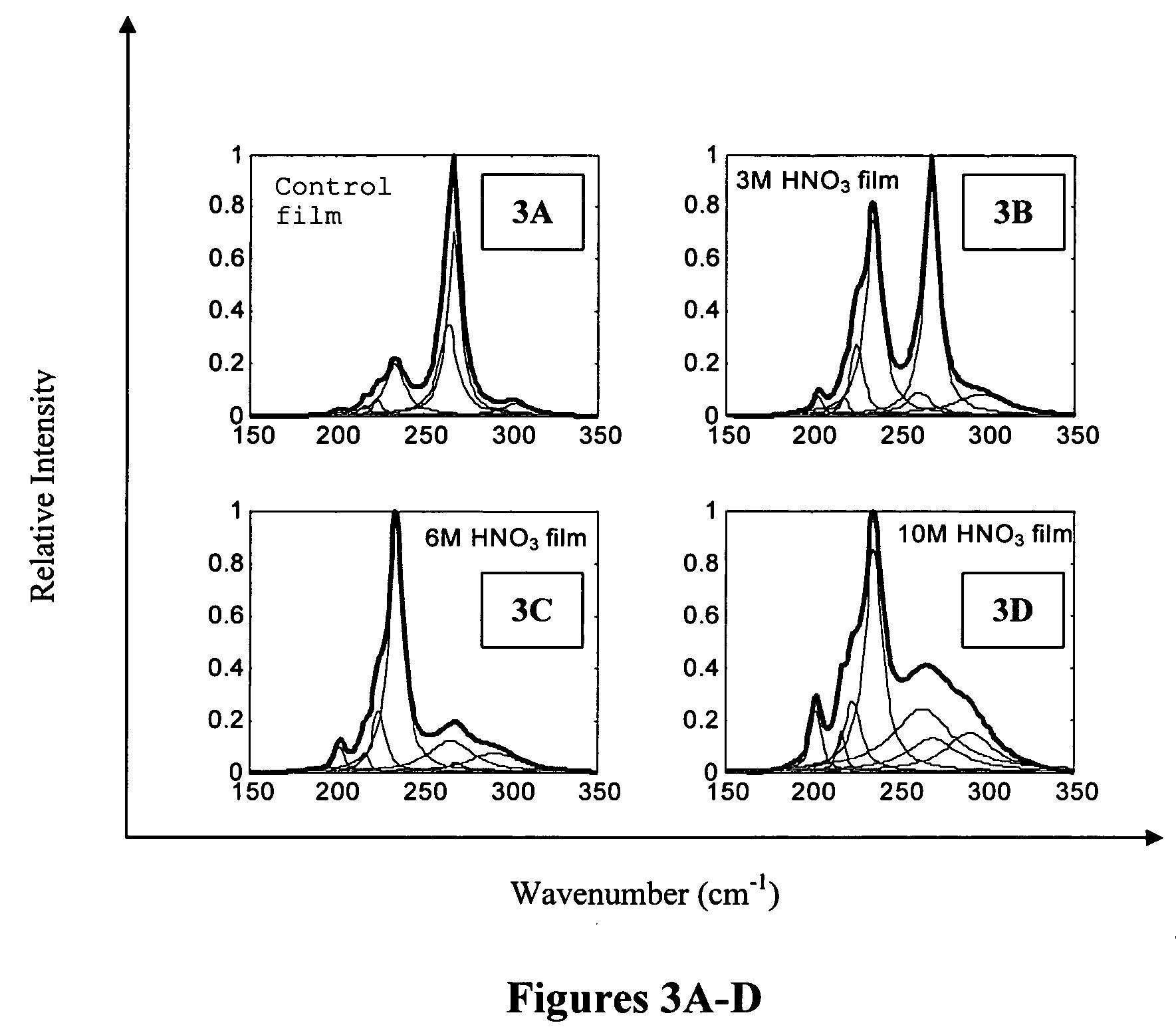

[0056] This example demonstrates a method for preparing a high strength film comprising predominantly single-wall carbon nanotubes (SWNT). Purified, HIPCO® small-diameter carbon nanotubes, comprising almost entirely single-wall carbon nanotubes, obtained from Rice University and Carbon Nanotechnologies, Inc., were made in a high temperature, high pressure, gas phase process through the disproportionation of carbon monoxide to primarily single-wall carbon nanotubes and CO2 using iron as the transition metal catalyst. (HIPCO is a registered trademark of Carbon Nanotechnologies, Incorporated, Houston, Tex.) 100 mg purified small-diameter carbon nanotubes were dispersed in 100 mls distilled water and sonicated for 2 hours using a Fisher Scientific bath sonicator (frequency 43 KHz, power 150 Watts). Nitric acid was then added to the dispersion to obtain a nitric acid concentration of 3M, 6M, or 10M. Each dispersion was then sonicated for 2 more hours, then refluxed for two hours, and sub...

example 2

[0059] Tensile mechanical properties and dc conductivity were measured on the small-diameter carbon nanotube films prepared in Example 1. The film samples tested in the tensile tests were 1 mm wide and 0.06 mm thick. The gauge length was 10 mm between the clamps. The tensile tests were conducted on a Rheometrics Solids Analyzer, RSA III, at a strain rate of 0.5% per second. The tensile test data are summarized in Table 1.

[0060] The mechanical studies showed a tensile strength of 74 MPa for the “as prepared” (heat-treated at 200° C.) small-diameter carbon nanotube film prepared with 10M nitric acid, a greater than seven-fold increase in tensile strength over the control film, which had a tensile strength of 10 MPa. The results also showed an initial tensile modulus of 5.0 GPa for the heat-treated small-diameter carbon nanotube film prepared with 10M nitric acid, a greater than six-fold increase in initial tensile modulus over the control film, which had an initial tensile modulus of...

example 3

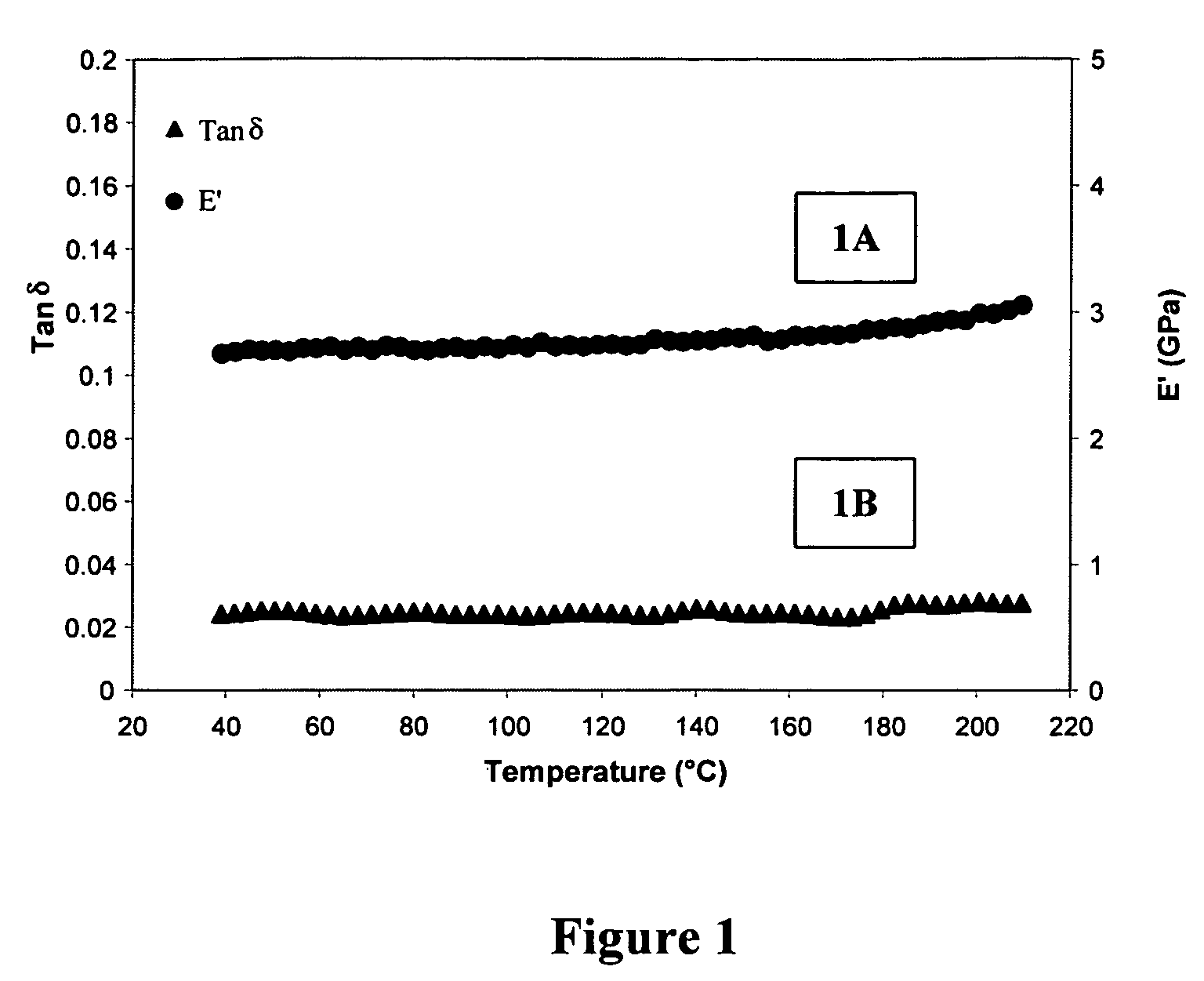

[0063] Dynamic mechanical analysis (DMA) as a function of temperature was done on the “as prepared” (200° C. heat-treated) small-diameter carbon nanotube films, prepared in Example 1, at a frequency of 10 Hz and at 0.1% dynamic strain using a RSA III Rheometrics Solids Analyzer. During the dynamic test, the static force adjusted automatically to 40% larger than dynamic force.

[0064] The results show a fairly constant E′ storage modulus for the “as prepared” small-diameter carbon nanotube films throughout the temperature range of about 30° C. to about 210° C., with a slight increase in storage modulus above 150° C. The Tan δ values were very low (i.e., about 0.02), indicating that the films are fairly elastic throughout the 30° C. to about 210° C. temperature range. A plot of the dynamic mechanical behavior for the “as prepared” film made with small-diameter carbon nanotubes processed in 6 M nitric acid is shown in FIG. 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com