Method for making a microelectronic interposer

a microelectronic interposer and microelectronic technology, applied in the direction of etching metal masks, coupling device connections, semiconductor/solid-state device details, etc., can solve the problems of weak electrical interconnections formed by deposited conductive materials in such drilled holes, high depth to diameter ratio, and large space consumed in assembly, so as to facilitate the movement of peripheral parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

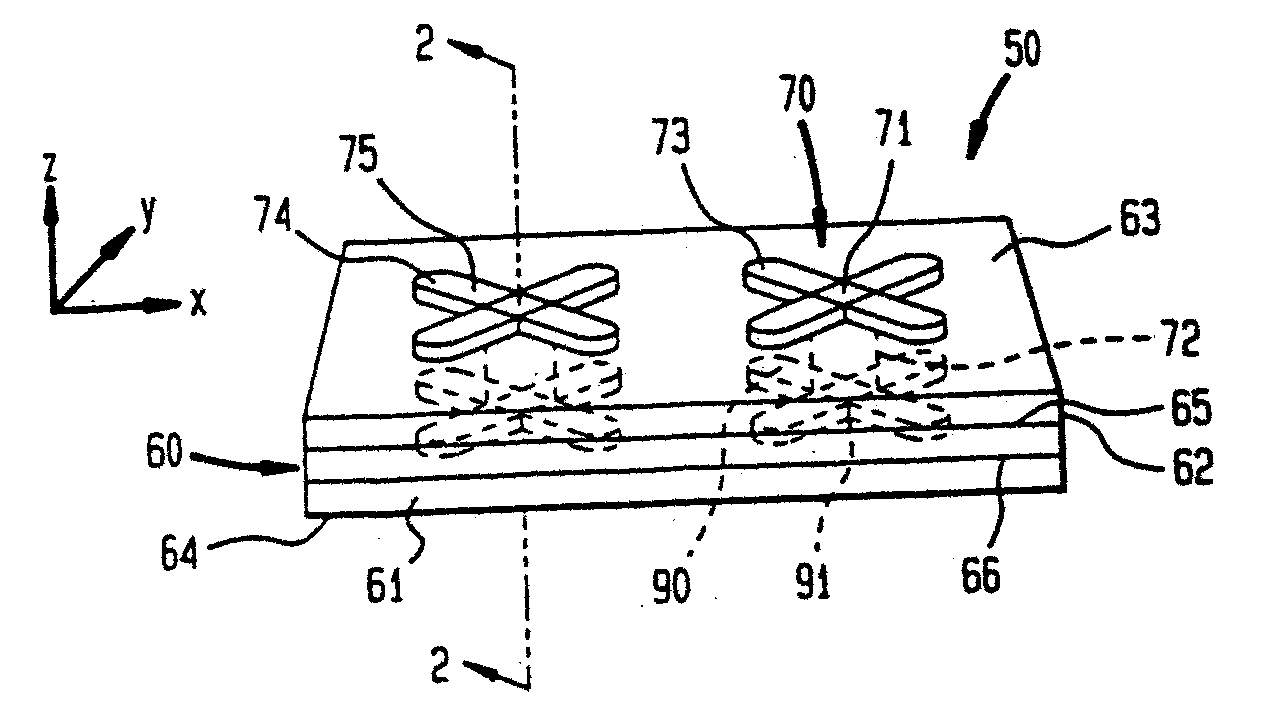

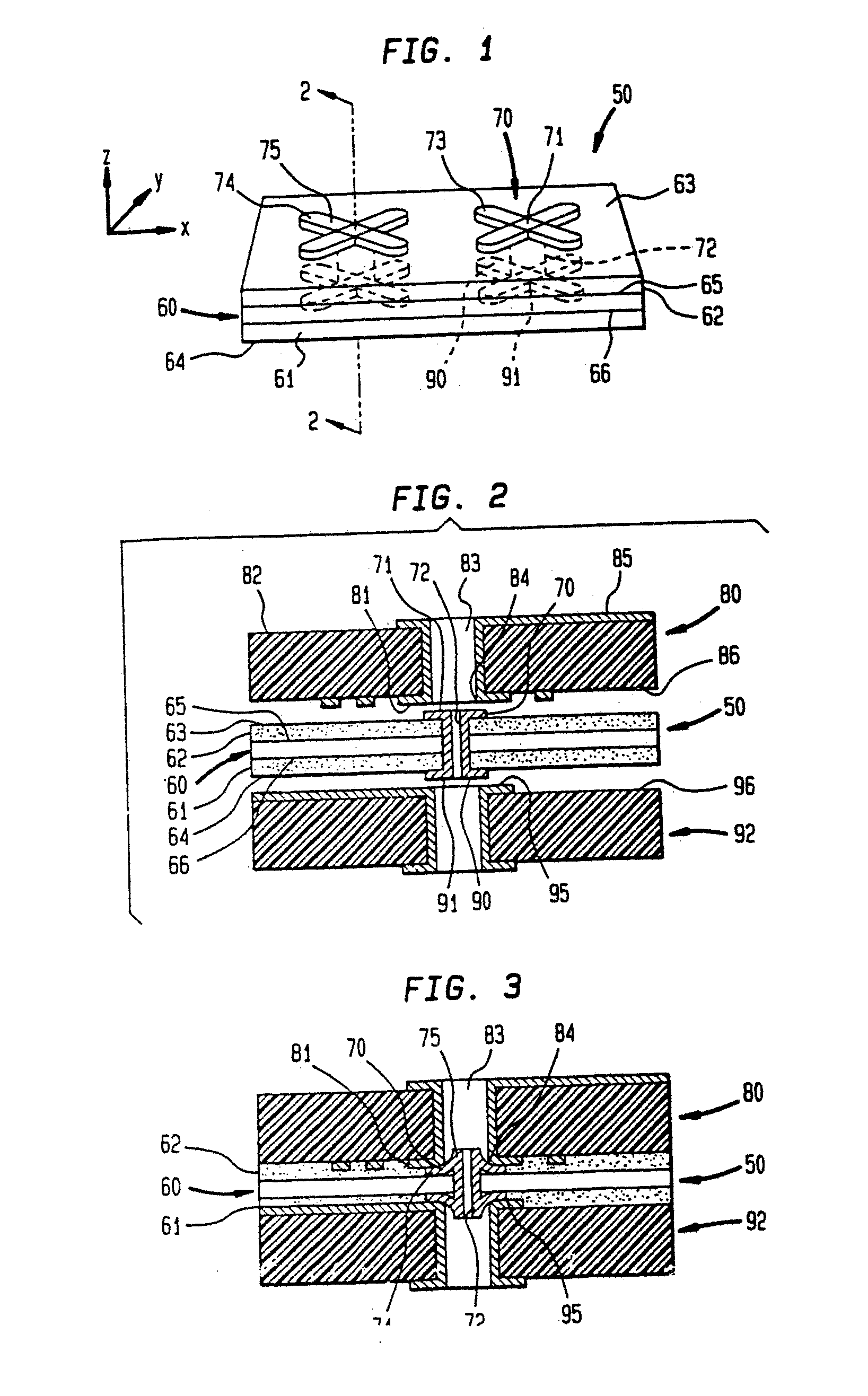

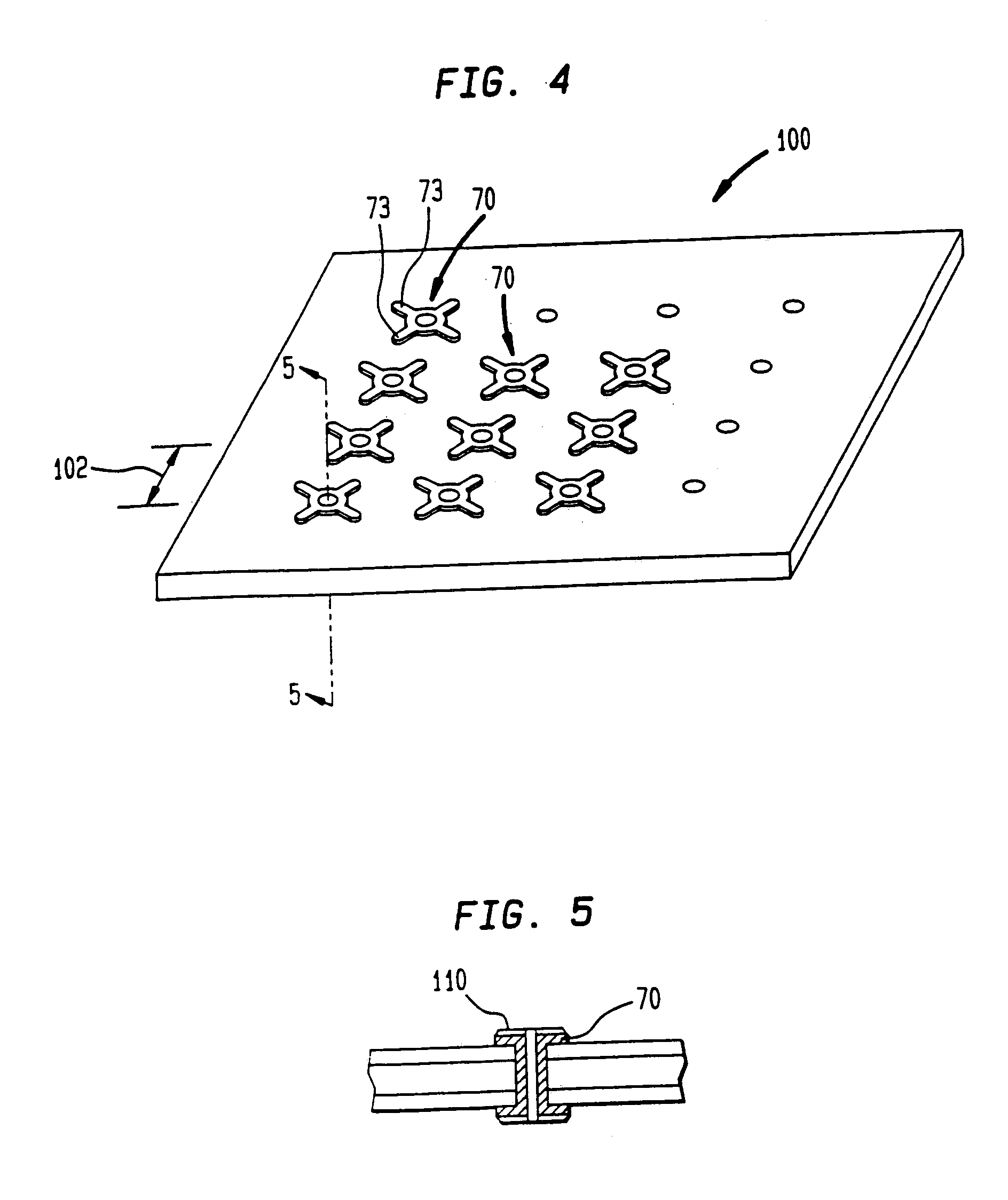

[0061] An interposer according to one embodiment of the invention, shown in FIG. 1, has a body 60 with a first major surface 65. The body 60 may be formed of a dielectric material such as polyimide, or of another non-conducting material. The top surface 65 of the body 60 extends in horizontal directions; i.e., directions x, y as shown in FIG. 1. A plurality of conductors 72 extend vertically, or in the z direction, into the body. In the preferred embodiment shown in FIG. 1, the conductors 72 extend through the body60. The conductors 72 may be elements formed by conductively plating vertical holes extending into the body 60 from the first surface 65. The conductors are formed of a structural conductive material such as copper, gold, tin or alloys thereof.

[0062] Each of the conductors 72 has a first end 71 positioned on or above the first major surface 65 of the body 60. Extending radially outward from the end 71 of the conductor is a contact 70. In the preferred embodiment shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com