Manifold for lube and seal oil apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

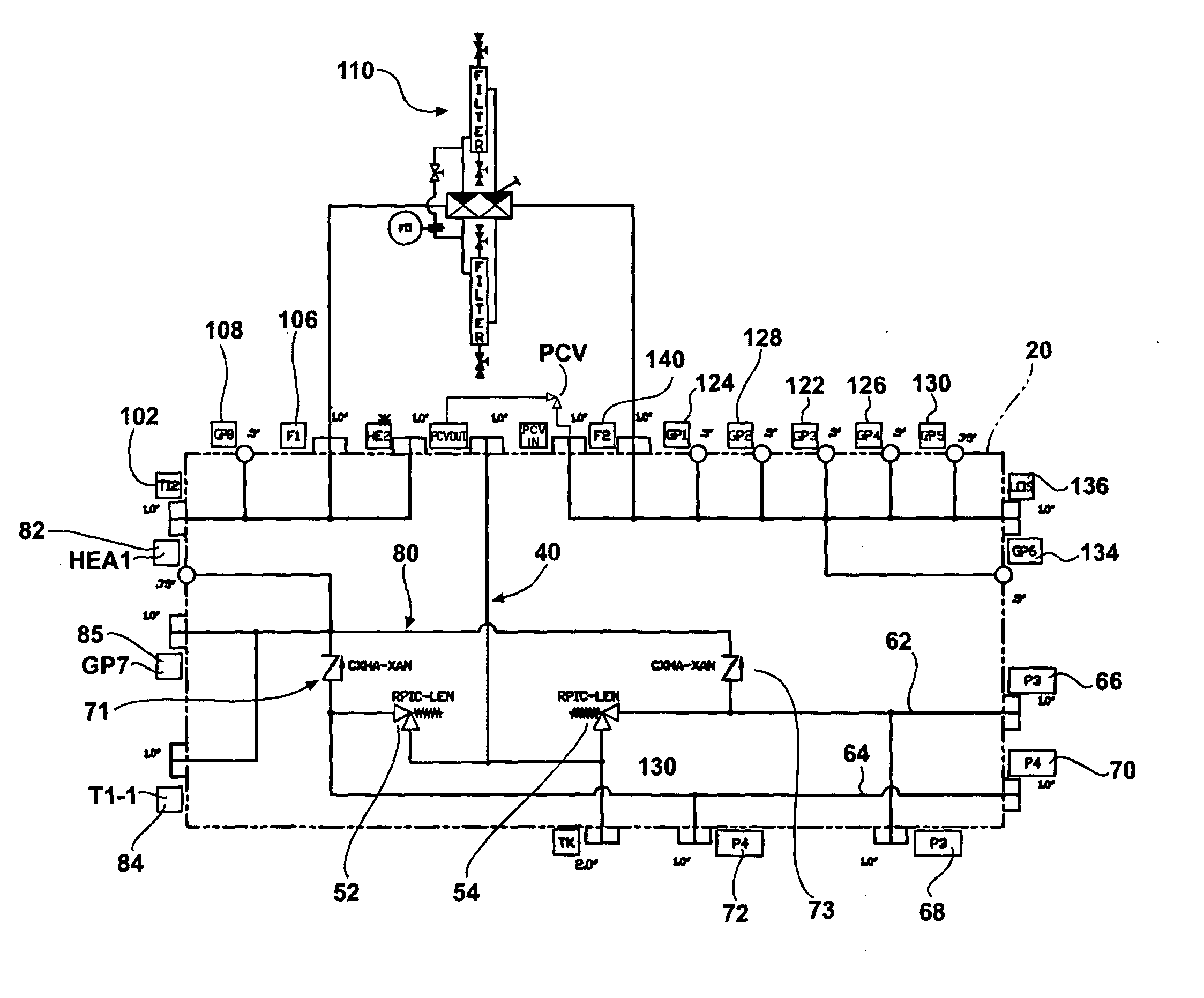

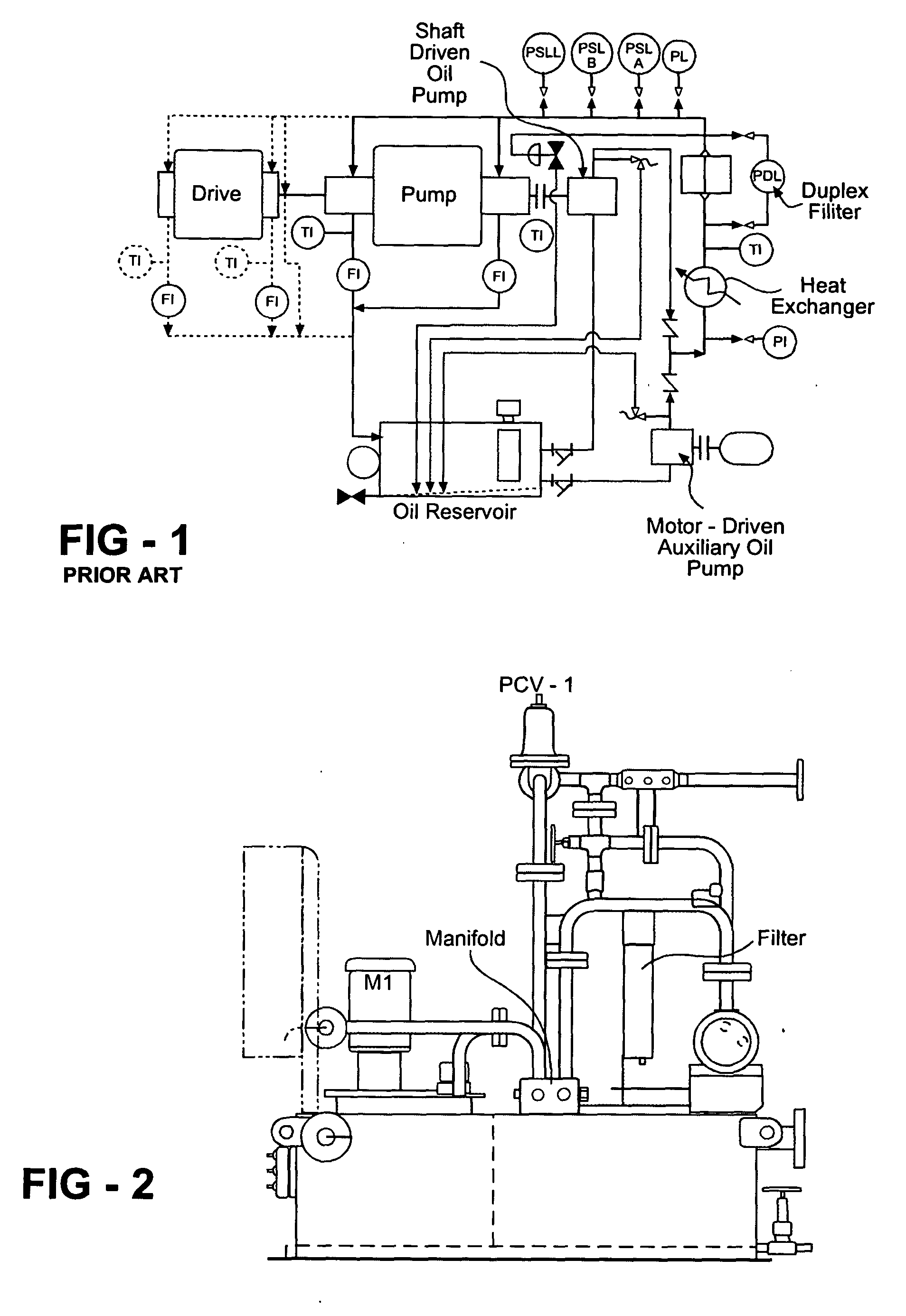

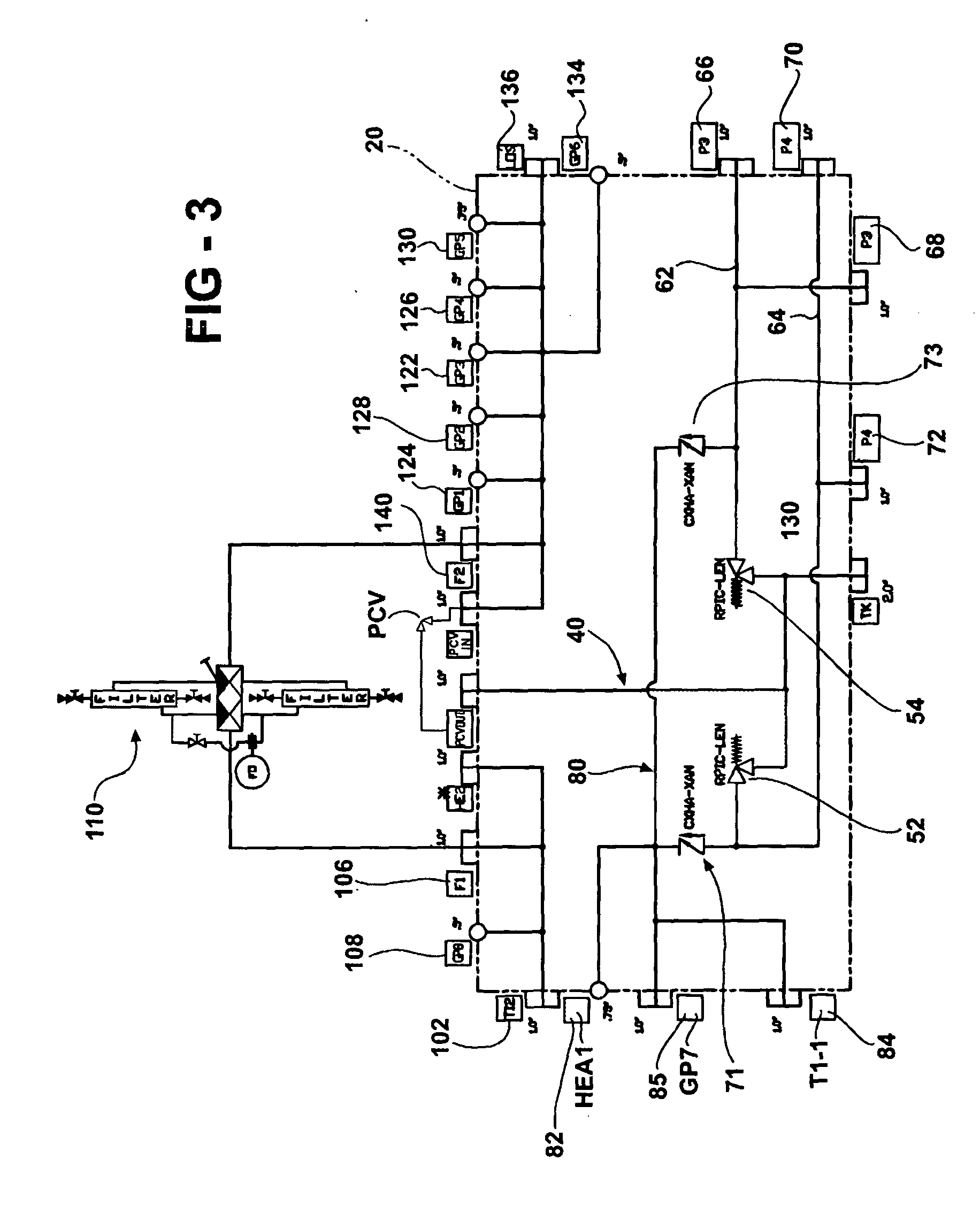

[0039] Referring now to the drawing, and to FIGS. 2-14 in particular, there is depicted a manifold 20 for use in connecting various components of a lube oil or seal oil supply system of a large process pump and drive apparatus.

[0040] The various components are attached to various ports on the manifold 20 and piped to other components in the pump and drive apparatus to complete the oil flow circuit of the pump and driver apparatus.

[0041] The manifold 20, according to the present invention, preferably is formed of a sold block of high strength material, such as a metal, preferably steel.

[0042] The block 20, which may have any shape, by example only has a generally polygonal shape in the form of a square or a rectangle formed by a front surface 22, a back or rear surface 24, opposed left and right side surfaces 26 and 28, a top surface 30 and a bottom surface 32.

[0043] A plurality of ports are formed on the various surfaces of the manifold 20 and internally coupled in fluid communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com