System and method for stabilizing a refrigerator storage bag to facilitate loading the bag with contents

a technology for storing bags and refrigerators, which is applied in the field of storage bags to facilitate the loading of the storage bags with contents, can solve the problems of troublesome process of transferring cleaned food items into the storage bags, complicated transfer of food items, bruises or other imperfections of fruits, etc., and achieves the effect of facilitating the pivoting of legs, and facilitating the movement of legs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

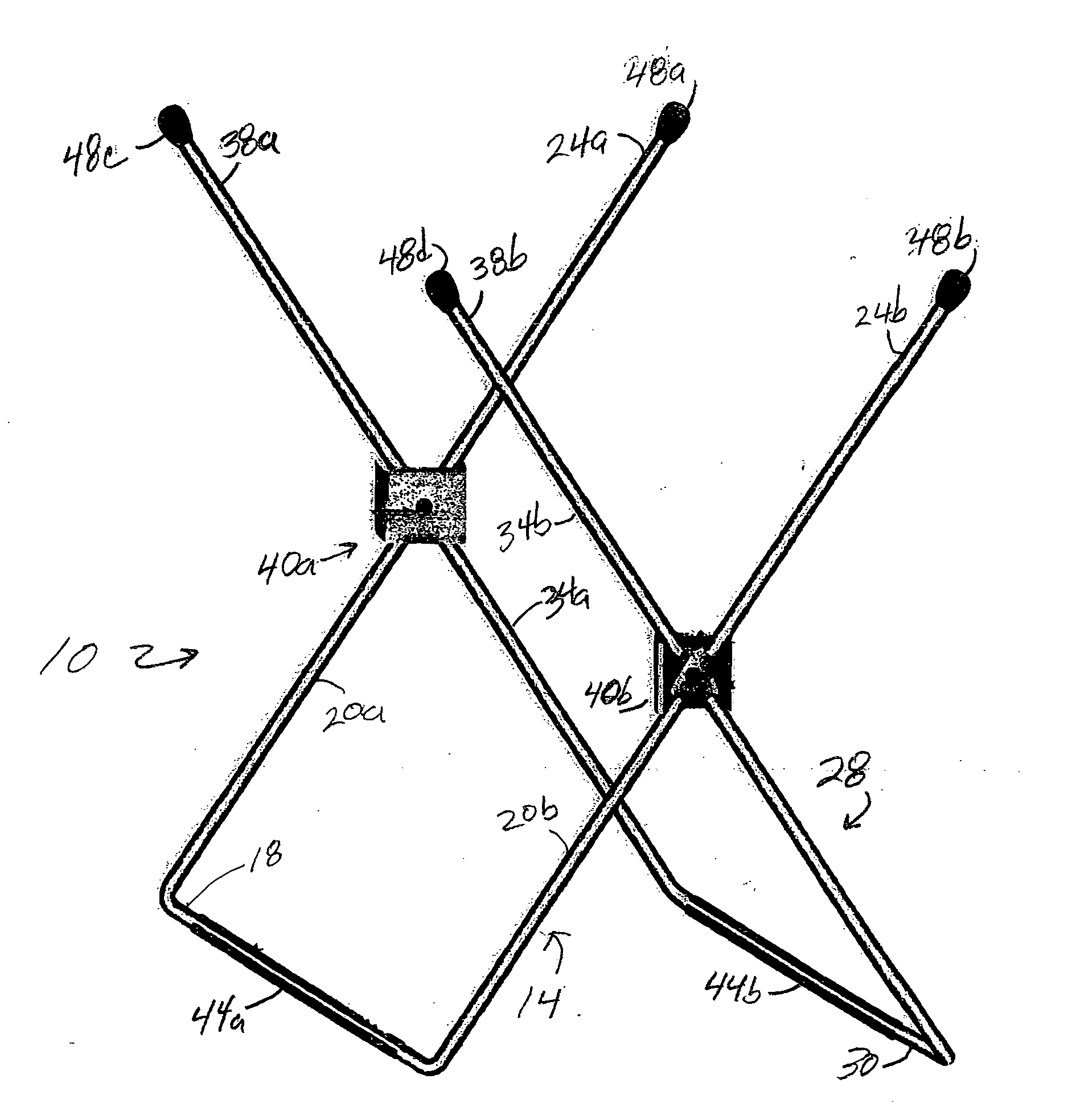

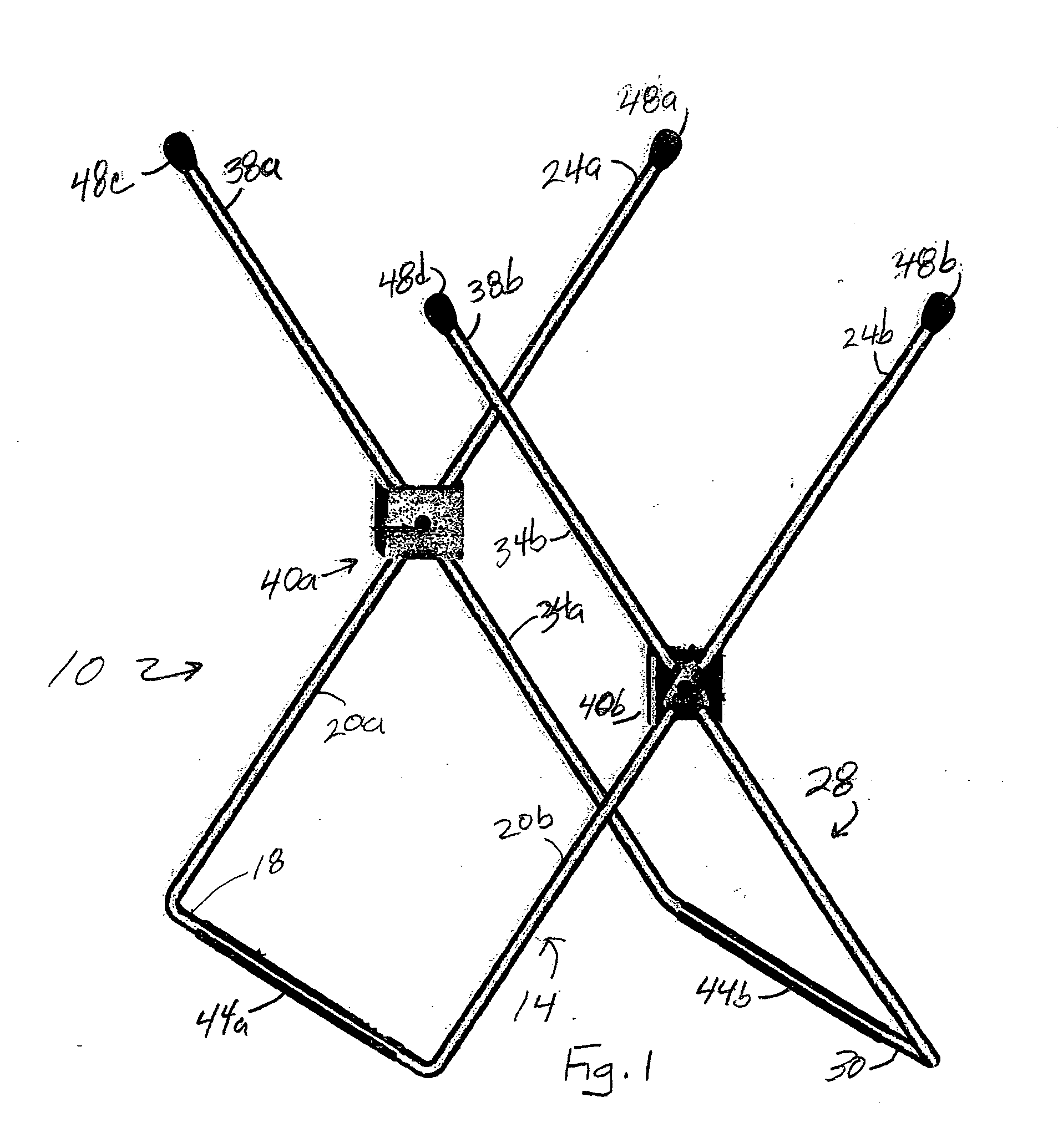

[0021]FIG. 1 shows a system 10 for stabilizing a refrigerator storage bag to facilitate the placement of material within the bag. The system 10 includes a first U-shaped frame member 14 having a closed end 18 and two legs 20a and 20b extending from the closed end 18 that terminate into distal ends 24a and 24b. The system 10 also includes a second U-shaped frame member 28 having a closed end 30 and two legs 34a and 34b extending from the closed end 30 that terminate into distal ends 38a and 38b. A first coupler 40a couples a first leg 20a of the first U-shaped member 14 to a first leg 34a of the second U-shaped member 28 and a second coupler 40b couples a second leg 20b of the first U-shaped member 14 to a second leg 34b of the second U-shaped member 28. The couplers limit the outward travel of the closed ends 18 and 30 of the U-shaped members 14 and 28 so that the first and the second distal ends of both U-shaped members remain stationary to hold in an open position a refrigerator b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com