Strings for racquets

a technology of strings and racquets, applied in the field of strings for racquets, can solve the problems of individual strings sliding over one another, wear against each other, and weakening of the tensile strength of the string,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

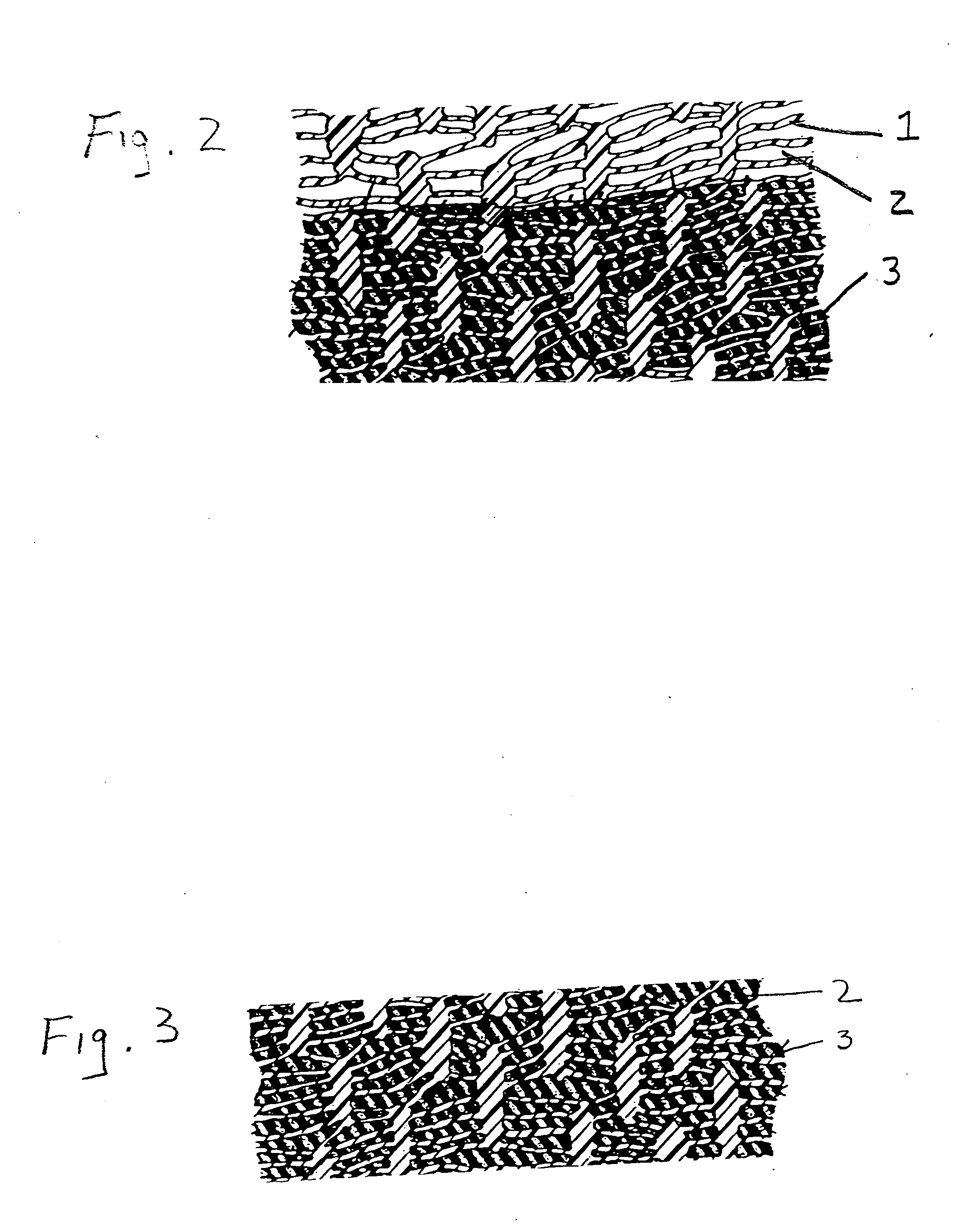

[0076] An example of a string according to the present invention was prepared by helically wrapping a 1.19 mm diameter multi-filament nylon string that was obtained from Prince Mfg. Co. with a polymer film impregnated with UV-curable adhesive. The string was made in the following manner:

[0077] Expanded PTFE film with a thickness of about 0.015 mm was obtained from WL Gore and Associates, Inc., Newark, Del. The expanded PTFE film had a bulk density of 0.7 g / cc, and was further characterized by a matrix tensile strength of about 41,000 psi in the longitudinal direction and a Bubble Point of 68 psi.

[0078] A 30 wt. % adhesive solution was prepared in isopropyl alcohol for impregnating the expanded PTFE film. The adhesive composition is 60 wt. % aliphatic polyester based urethane diacrylate oligomer blended with ethoxylated trimethylol propane triacrylate (available from Sartomer Company, Exton, Pa. as CN963E75), 32 wt. % triacrylate acid ester (available from Sartomer Company as CD905...

example 2

[0084] A second, slightly smaller example string was made according to the present invention by helically wrapping a 1.13 mm diameter multi-filament nylon string that was obtained from Prince Mfg. Co. with a polymer film impregnated with UV-curable adhesive. The string was made in the manner described above in Example 1 by wrapping the base string with the same ePTFE film impregnated with a low temperature adhesive used in Example 1.

[0085] The final string diameter was 1.18 mm. As reflected in Table 1, the inventive string shows much better durability than a comparable diameter nylon string, and a similar dynamic modulus.

Test Methods

Durability

[0086] The durability test apparatus is depicted in FIG. 10. Tennis balls were alternatively fired at 60 MPH from two ball machines 15, 15′ such that the balls contacted a simulated racquet frame 17 at a rate of one every 4 seconds. Ball speed was measured at each ball machine using laser speed recording equipment. The simulated racquet st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com