Coated particles and pharmaceutical dosage forms

a technology of coated particles and dosage forms, applied in the field of pharmaceutical industry, can solve the problems of limited use, scarce publications available, and no general way to predict optimal solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

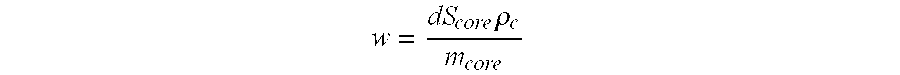

Method used

Image

Examples

example 1

Composition of One Coated Tablet

[0169] 1.1. Tablet Core

TABLE 2Composition of the coreIngredientMass (mg)Atorvastatin (in the form of atorvastatin Ca)20.00Microcrystalline cellulose143.20Lactose monohydrate34.80Crosslinked carboxymethylcellulose19.20Hydroxypropyl cellulose2.00Polysorbate 802.60Magnesium oxide26.00Colloidal silicon dioxide1.20Magnesium stearate1.00

Preparation of Tablet Core

[0170] Atorvastatin, half of microcrystalline cellulose, lactose monohydrate, half of crosslinked carboxymethylcellulose and 11% of the total magnesium oxide were homogeneously mixed and granulated with a solution of hydroxypropyl cellulose and polysorbate in water. The granulate was dried in a fluid bed dryer and the sieved granulate was homogeneously mixed with the other half of microcrystalline cellulose and crosslinked carboxymethylcellulose, the rest of magnesium oxide, colloidal silicon dioxide and magnesium stearate. The homogeneous granulate was compressed into tablets, mass 250 mg, on...

example 2

Composition of One Coated Tablet

[0175] 2.1. Tablet Core

TABLE 5Composition of the coreIngredientMass (mg)Atorvastatin (in the form of atorvastatin Ca)10.00Microcrystalline cellulose153.20Lactose monohydrate34.80Crosslinked carboxymethylcellulose19.20Hydroxypropyl cellulose2.00Polysorbate 802.60Magnesium oxide26.00Colloidal silicon dioxide1.20Magnesium stearate1.00

Preparation of Tablet Core

[0176] Atorvastatin, 53% of the total microcrystalline cellulose, lactose monohydrate, half of crosslinked carboxymethylcellulose and 11% of the total magnesium oxide were homogeneously mixed and granulated with a solution of hydroxypropyl cellulose and polysorbate in water. The granulate was dried in a fluid bed dryer and the sieved granulate was homogeneously mixed with the rest of microcrystalline cellulose, crosslinked carboxymethylcellulose and magnesium oxide, colloidal silicon dioxide and magnesium stearate. The homogeneous granulate was compressed into tablets, mass 250 mg, on a conven...

example 3

Composition of One Coated Tablet

[0181] 3.1. Tablet Core

TABLE 8Composition of the coreIngredientMass (mg)Atorvastatin (in the form of atorvastatin Ca)10.00Microcrystalline cellulose153.20Lactose monohydrate34.80Crosslinked carboxymethylcellulose19.20Hydroxypropyl cellulose2.00Polysorbate 802.60Magnesium ixide26.00Colloidal silicon dioxide1.20Magnesium stearate1.00

Preparation of Tablet Core

[0182] Atorvastatin, 53% of the total microcrystalline cellulose, lactose monohydrate, half of crosslinked carboxymethylcellulose and 11% of the total magnesium oxide were homogeneously mixed and granulated with a solution of hydroxypropyl cellulose and polysorbate in water. The granulate was dried in a fluid bed dryer and the sieved granulate was homogeneously mixed with the rest of microcrystalline cellulose, crosslinked carboxymethylcellulose and magnesium oxide, colloidal silicon dioxide and magnesium stearate. The homogeneous granulate was compressed into tablets, mass 250 mg, on a conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pKa | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com