Method and apparatus for producing amorphous alloy sheet, and amorphous alloy sheet produced using the same

a technology of amorphous alloy and production method, which is applied in the field of producing amorphous alloy sheets and amorphous alloy sheets produced using the same, can solve the problems of not being suitable for mass not being cost effective, and not being able to meet the requirements of bulk production of amorphous alloy sheets, and achieves low production cost, high quality, and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

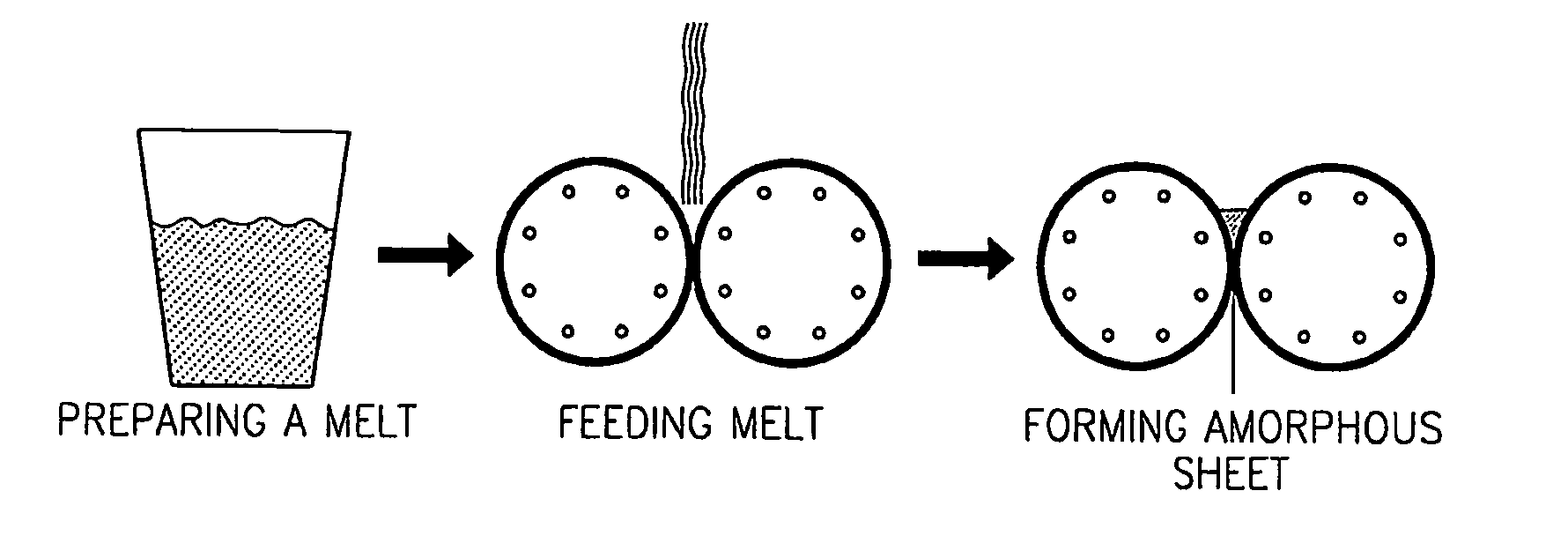

Method used

Image

Examples

example

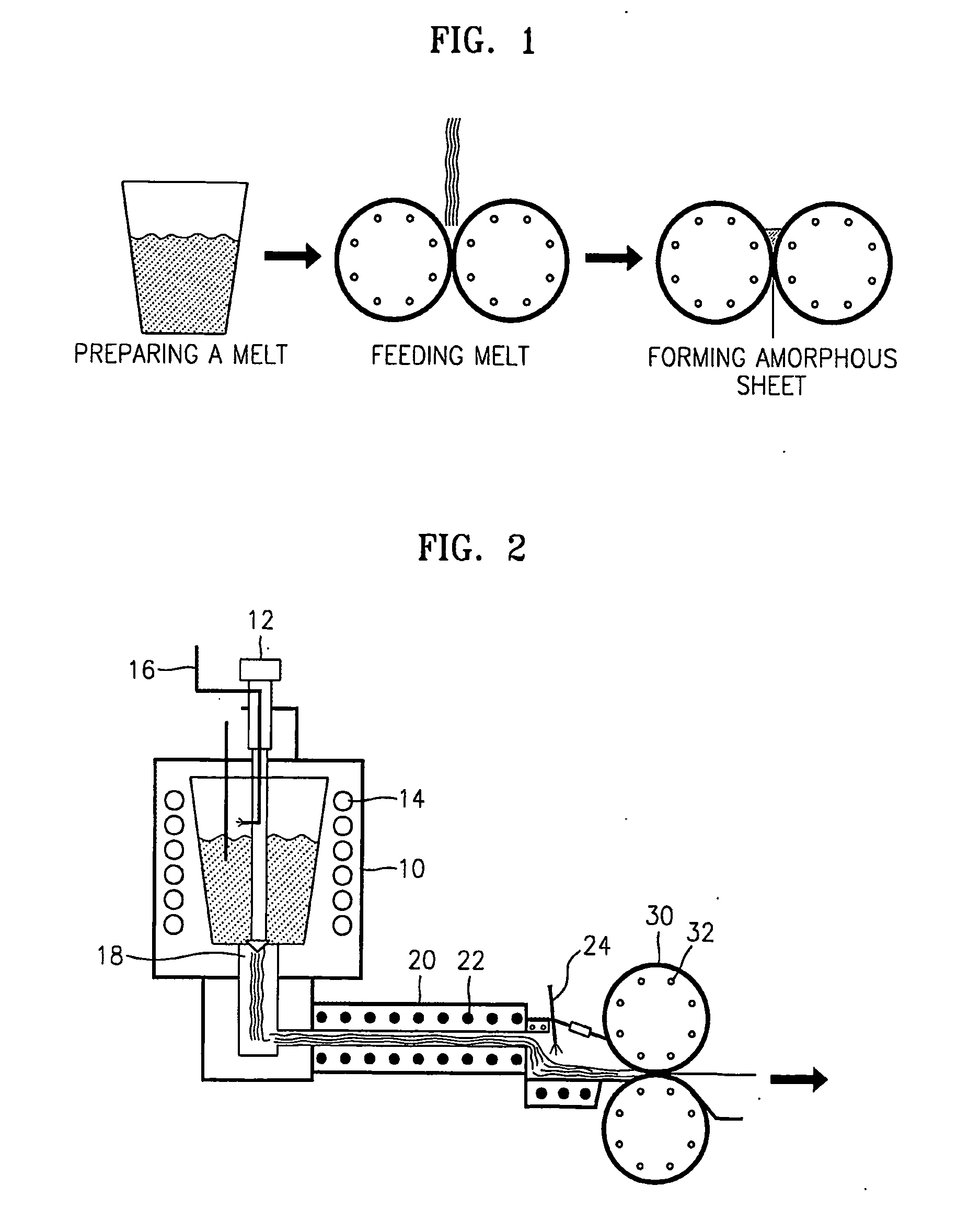

[0062] In this Example, a copper-based alloy with its chemical composition presented in Table 1 was used as a mother alloy. An apparatus shown in FIG. 2 was used.

TABLE 1Chemical composition of mother alloyElementsCuTiZrNiSnSiContent (atomic %)473311621

3 kg of a copper-based mother alloy was loaded into a high purity graphite crucible and then maintained at a temperature of about 1,400° C. for about 60 minutes to be completely melted into a liquid phase. A copper-based mother alloy melt thus obtained was discharged while being maintained at a temperature of about 1,200° C., and then transferred into an inlet between rolling rolls of the strip casing apparatus

[0063] The rotation rate, surface temperature, and gap of the rolling rolls were about 2.0 cm / sec, about 20° C., and about 2 mm, respectively. Under these process conditions, amorphous alloy sheets of 1 m in length, 10 cm in width, and 2 mm in thickness were prepared.

[0064] The non-crystallinity of the copper-based amorphous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com