[0009] The present invention is directed to a

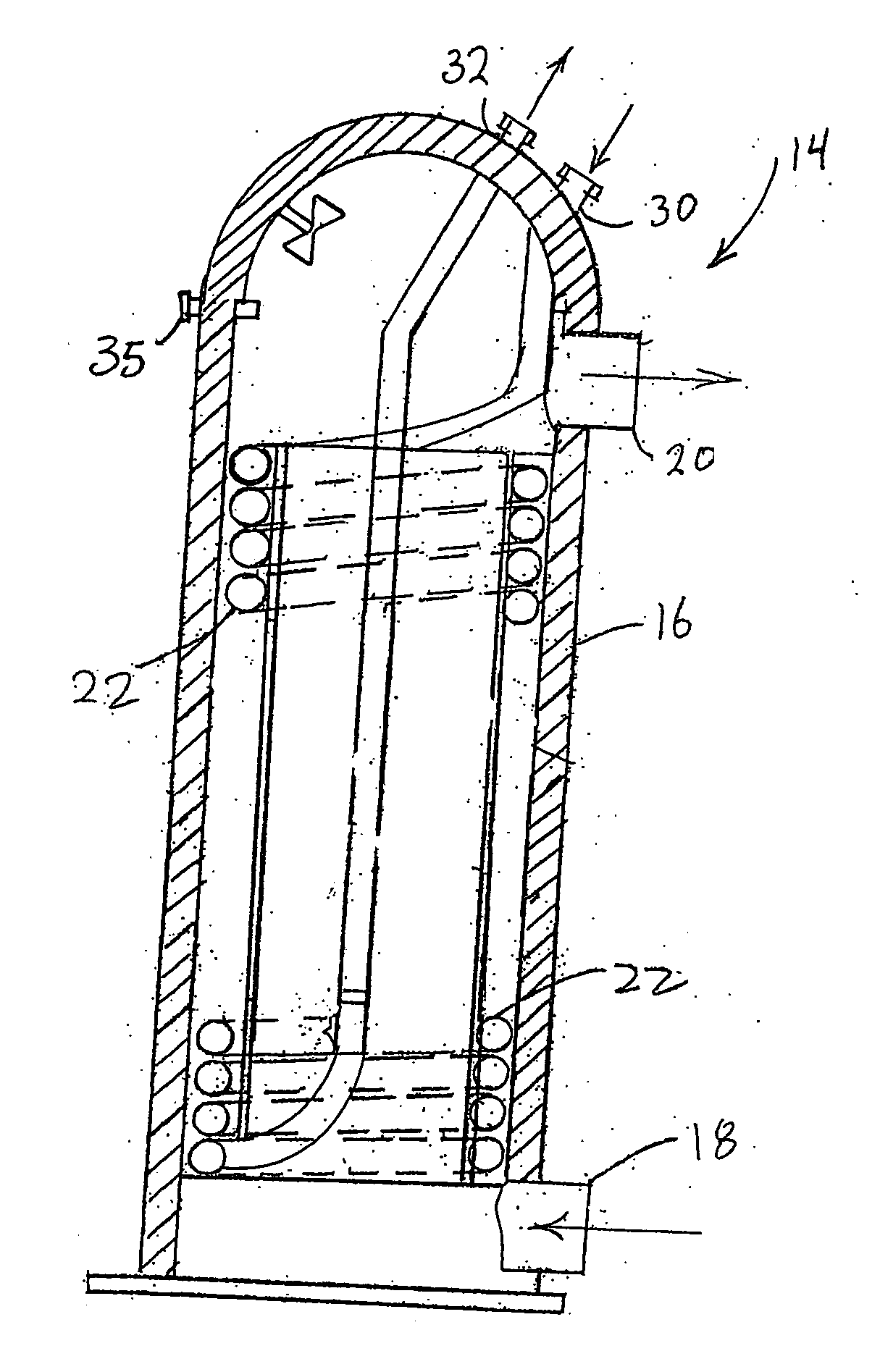

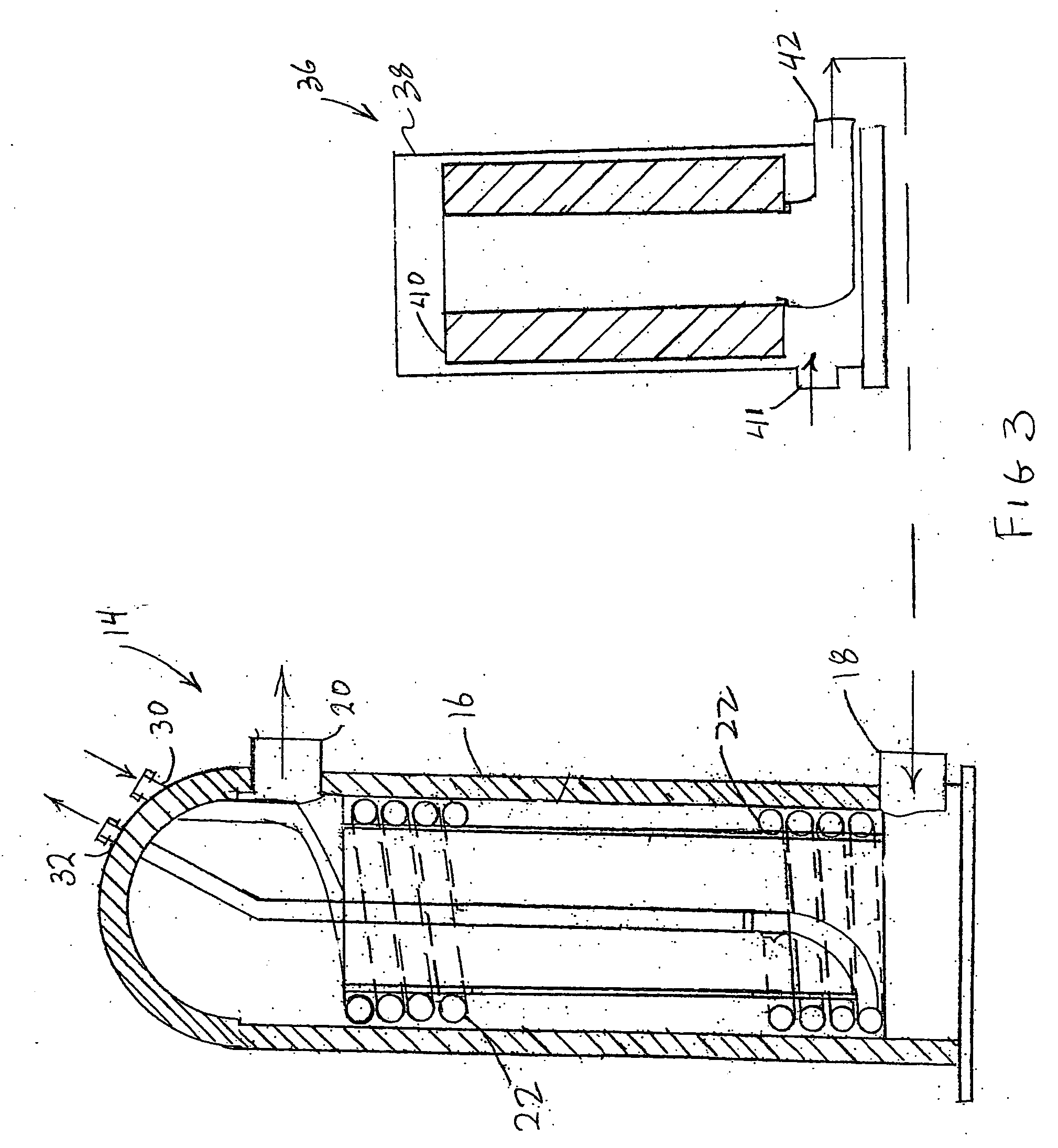

system for heating water of the type used primarily for recreational facilities such as, but not limited to, swimming pools, hot tubs, spas, etc. Moreover, the system of the present invention comprises a heater assembly including a housing, which may differ in dimension and configuration dependent upon a specific application, but is structured to facilitate the passage of the water therethrough. A heating element is mounted within the housing and is structured, disposed and configured to facilitate and maximize heat exchange between the heat exchange fluid passing through the heating element and the water within and / or passing through the housing.

[0010] In order to accomplish appropriate

processing of the heat exchange fluid, a compressor assembly is connected in fluid communication with the heating element but is disposed at a remotely spaced distance there from. More specifically, the compressor is located a sufficient distance from the point of delivery of the heating water in order to eliminate or reduce any inconvenience of participants of the

recreational facility which may be caused by the operating characteristics of the compressor assembly and its associated operative components. By way of example only and as explained in greater detail hereinafter, the continued or periodic operation of the compressor assembly and the components and control assemblies associated therewith, may be sufficiently noisy to be annoying to occupants of a swimming

pool if the compressor assembly is located in the general proximity of the pool or other

recreational facility to which the heated water is supplied.

[0011] According, one feature of the

heating system of the present invention is the remote location or distancing of the heater assembly and the compressor assembly from one another, wherein the heater assembly is located in the general vicinity and much closer to the swimming pool or other recreational facility to which the heated water is being delivered. This

proximate location of the heater assembly further facilitates a heating of the pool water in close proximity to its area of delivery and use thereby rendering the overall

heating system more efficient. Further structural features include a detachable connection between the heating element and / or housing and the compressor assembly and its associated operative components thereby facilitating installation, replacement, repair and maintenance of the heater assembly and its components.

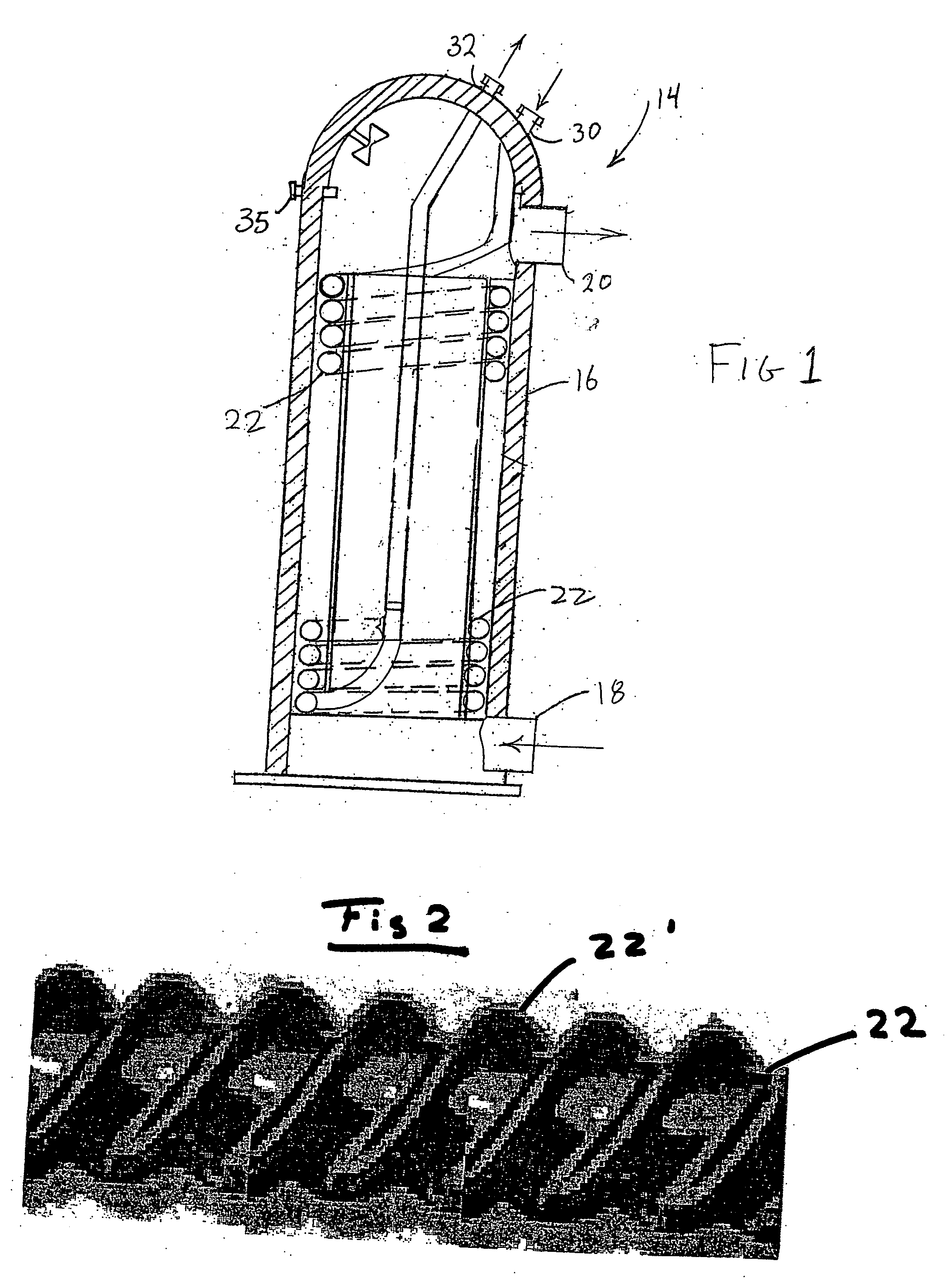

[0012] It is of course recognized that efficient heating of the recreational water, while passing through the housing, is based, at least in part, on the disposition, size and configuration of the heating element disposed in heat transferring relation to the water passing through the housing. As such, the heating element comprises an exterior surface having a predetermined configuration structured to maximize heat exchange with the water within the housing. Moreover, while the exterior surface configuration of the heating element may vary within certain prescribed parameters, a most preferred predetermined configuration of the exterior surface of the heating element is generally defined by a substantially twisted orientation of said heating element about a central longitudinal axis thereof. The “twisted orientation” of the heating element will result in an exterior surface configuration which may be generally described as a “twirled” or even “thread-like” configuration extending along all or at least a significant majority of the heating element. As a result, the exterior surface which comes in contact with the water being heated is effectively increased based upon the overall length of the heating element mounted within the interior of the housing. The resulting predetermined twisted orientation thereby comprises an increased exposed outer or exterior surface of the heating element in order to “maximize” or significantly increase the heat exchange area and the degree of heat exchange between the heat exchange fluid passing through the heating element and the water being exposed to the heating element within the housing. Another feature directly associated with the heating element is it being preferably formed from a

titanium material to further facilitate heat exchange. In addition, the

titanium has a long and effective operable life in that it is resistant to

erosion and

corrosion thereby extending the operable life of the entire

heating system. However, it is emphasized that the heating element may be formed of materials other than

Titanium such as, but not limited to cupro

nickel and / or stainless steel.

[0014] Yet another structural modification and preferred embodiment of the present invention is the direct combining of the filter assembly and the heating element in a common housing, wherein a structural modification of this cooperative embodiment includes the elongated heating element disposed in a substantially

helical configuration and in surrounding relation to the heater assembly. In this embodiment, the overall size and / or configuration of the

filter element may be reduced or structurally modified so as to facilitate its cooperative and direct placement relative to the heating element in a manner which facilitates both the filtering and heating of the water passing through the common housing.

Login to View More

Login to View More  Login to View More

Login to View More