Excavating machine for rocky and other soils

a technology of excavating machine and soil, which is applied in the direction of mechanical machine/dredger, soil shifting machine/dredger, construction, etc., can solve the problems of ineffective excavating of spoil from a trench, large mass of crawler tractors, and inability to drive on hard surface roadways, etc., to reduce the mass of drive tractors, operate more efficiently, and efficiently remove spoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This invention discloses an improved excavating machine for cutting a trench through the earth. The invention particularly discloses an improved excavating machine for trenching through rocky soils. Prior improvements to wheel trenchers invented in whole or in part by one of the instant inventors are shown in U.S. Pat. Nos. 4,890,670; 5,873,186; 5,943,798; and 6,055,750; the disclosures of each of which are incorporated herein by this reference.

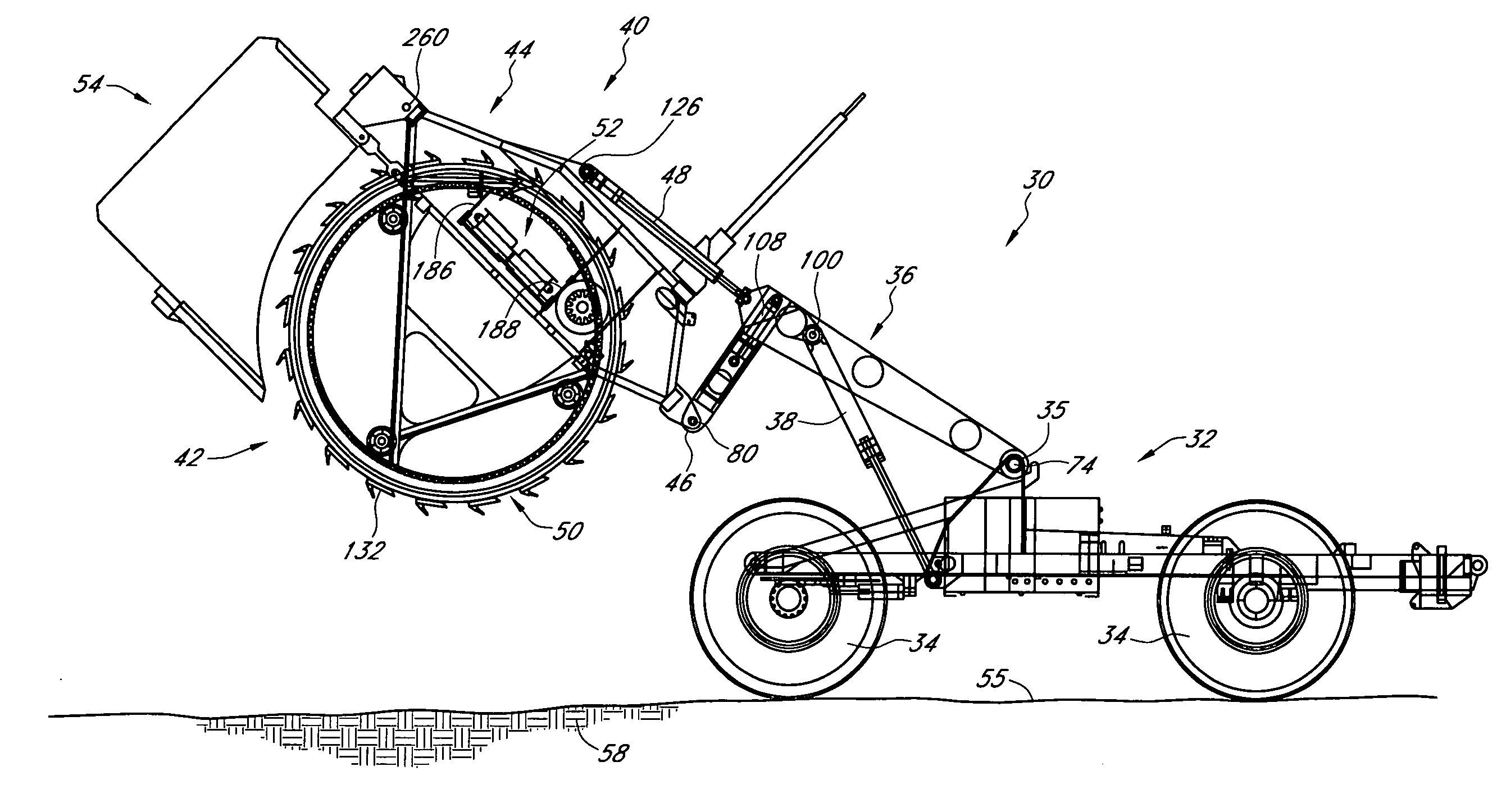

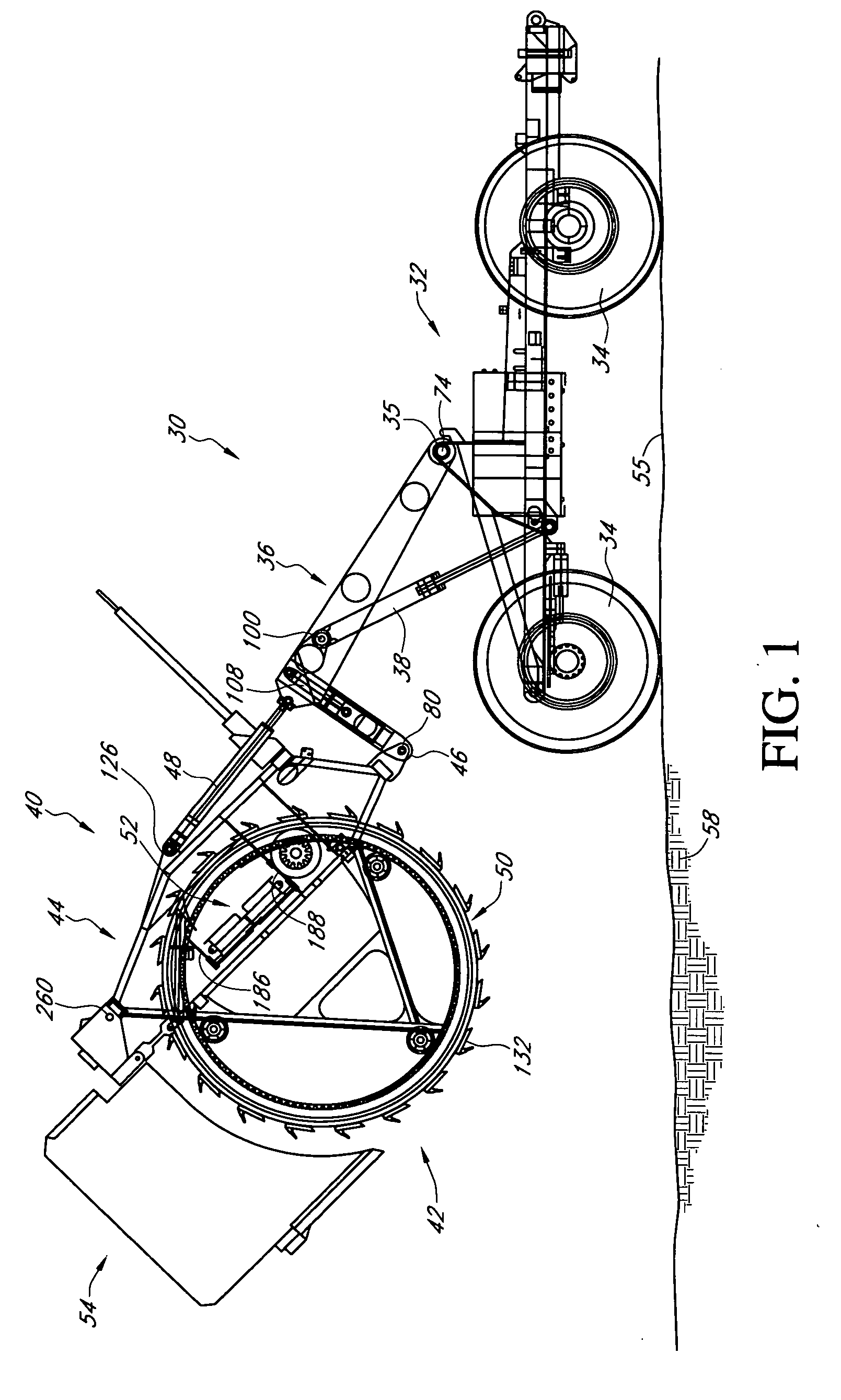

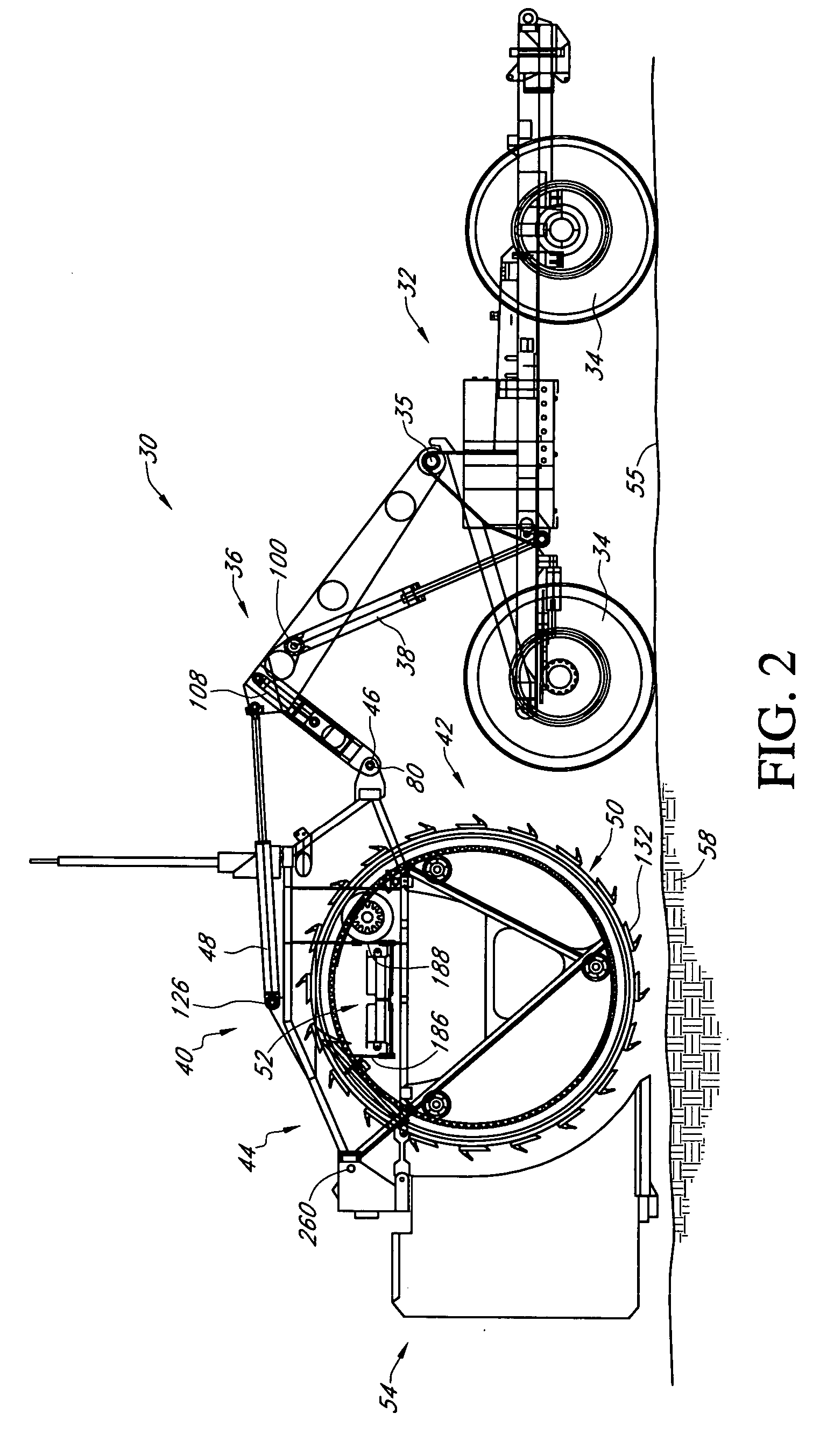

[0041] Referring to FIG. 1, the numeral 30 generally designates the excavating machine of the present invention. The excavating machine 30 includes a power unit vehicle 32 supported by wheels 34. Pivotally mounted about a horizontal axis 35 on the power unit vehicle 32 is an L-arm assembly 36 which is adapted to be raised and lowered by means of a hydraulic cylinder 38. Pivotally mounted to the L-arm assembly 36 is earth cutting assembly 40. The earth cutting assembly 40 of the preferred embodiment comprises a rock wheel trencher asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com