Firearm projectile with bonded rear core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

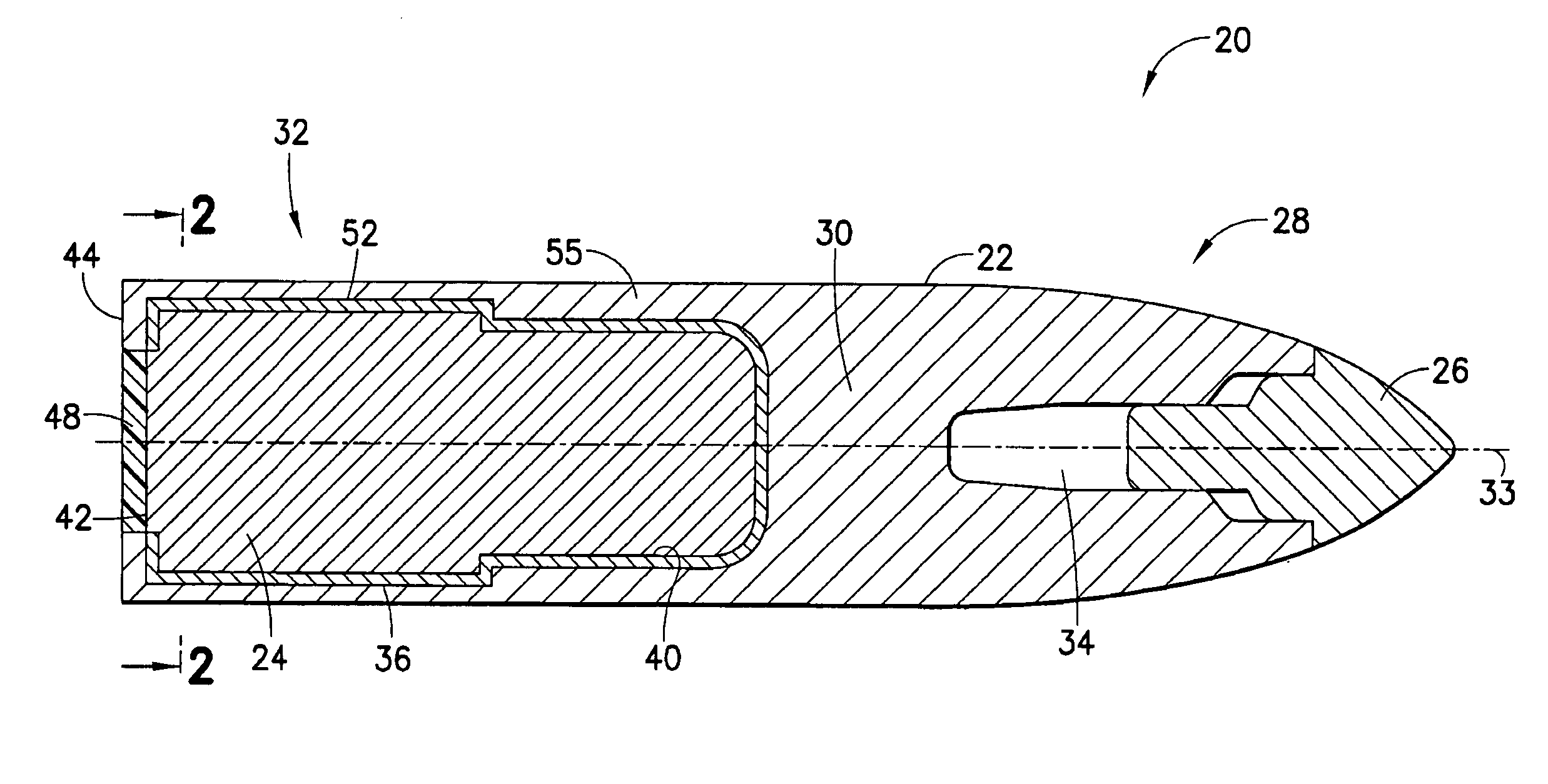

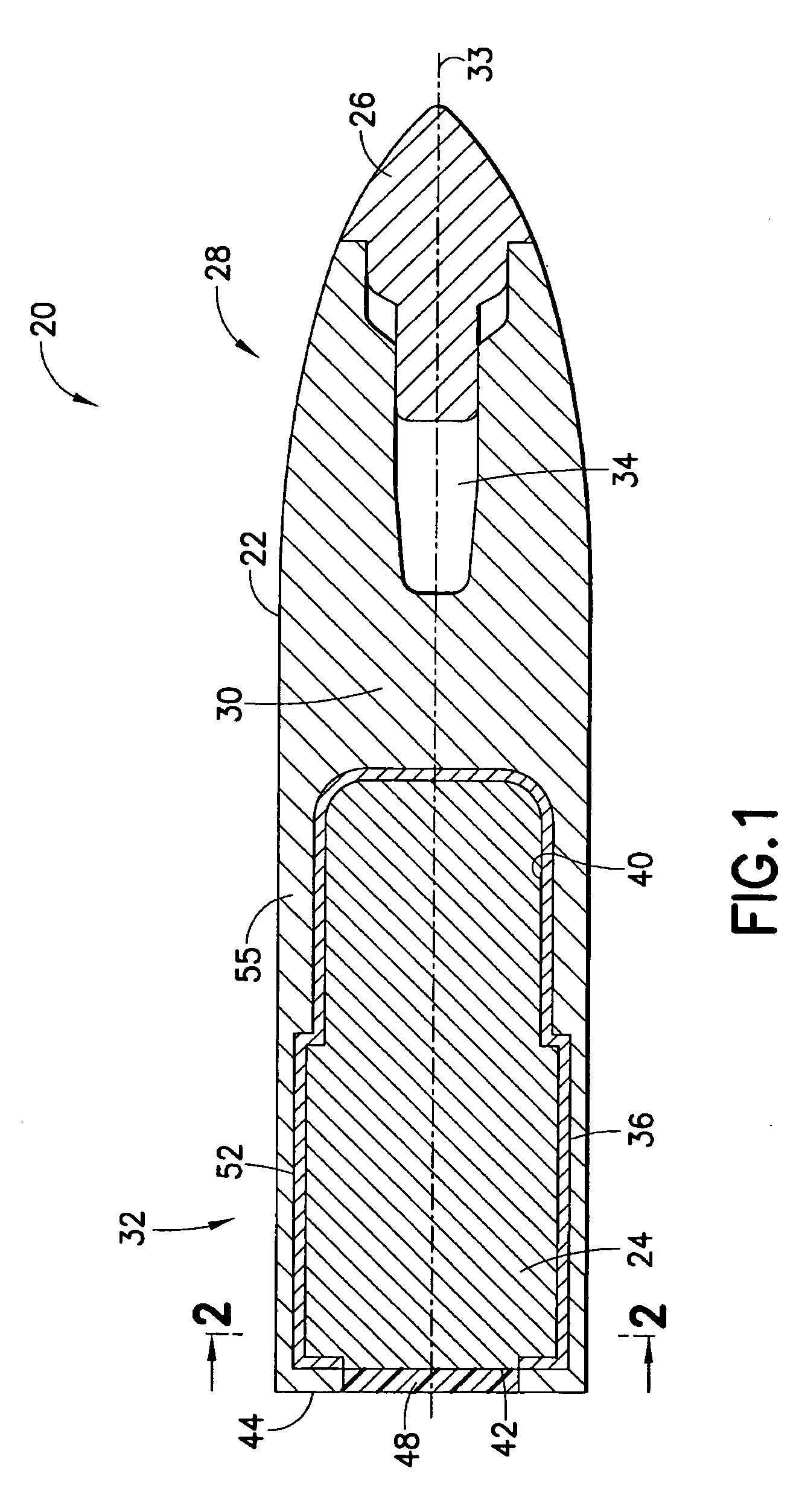

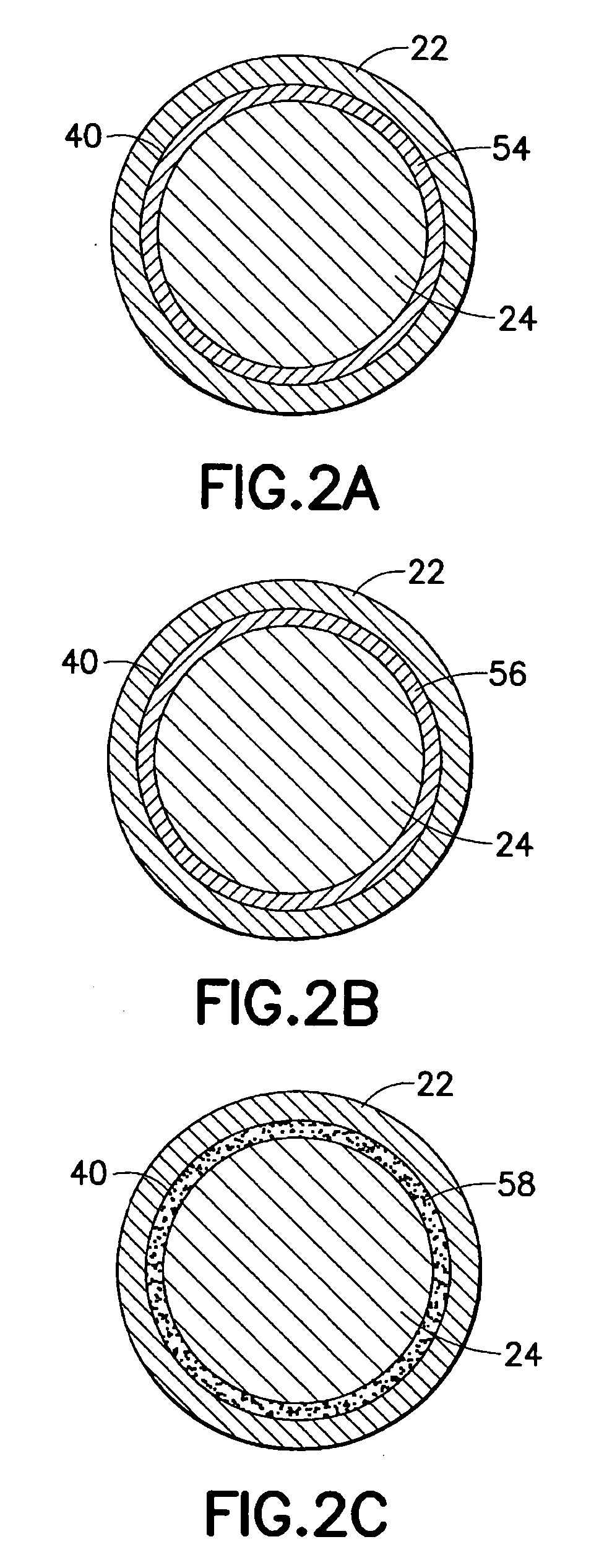

[0018] Referring now to the drawings in which like reference numerals indicate like parts, and in particular, to FIG. 1, the present invention is a controlled expansion projectile 20 having a metal jacket 22, a dense core 24, and a tip 26.

[0019] Metal jacket 22 includes a nose portion 28, a middle portion 30, and a heel portion 32. Metal jacket 22 is typically a substantially cylindrical body formed around a longitudinal axis 33. Metal jacket 22 is generally formed of a unitary construction having an H-shaped cross-section as taught in U.S. Pat. No. 3,003,420, and fabricated from a copper alloy as taught in U.S. Pat. No. 5,385,101, both of which are hereby incorporated by reference as if disclosed herein in their entirety. Metal jacket 22 may be fabricated from alloy CDA 210 or similar, which is commonly used in commercially available bullet jackets. Alternatively, metal jacket 22 may be fabricated from a copper-zinc alloy such as CDA 220 or CDA 226, or a pure CDA 100 series metal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com