Three-dimensional finger glove

a three-dimensional, glove technology, applied in the direction of brushes, protective garments, domestic applications, etc., can solve the problems of uneconomical competitiveness of product(s) to manufacture, increased production costs, and undesirable stiffness, and achieve the effect of facilitating finger inserting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

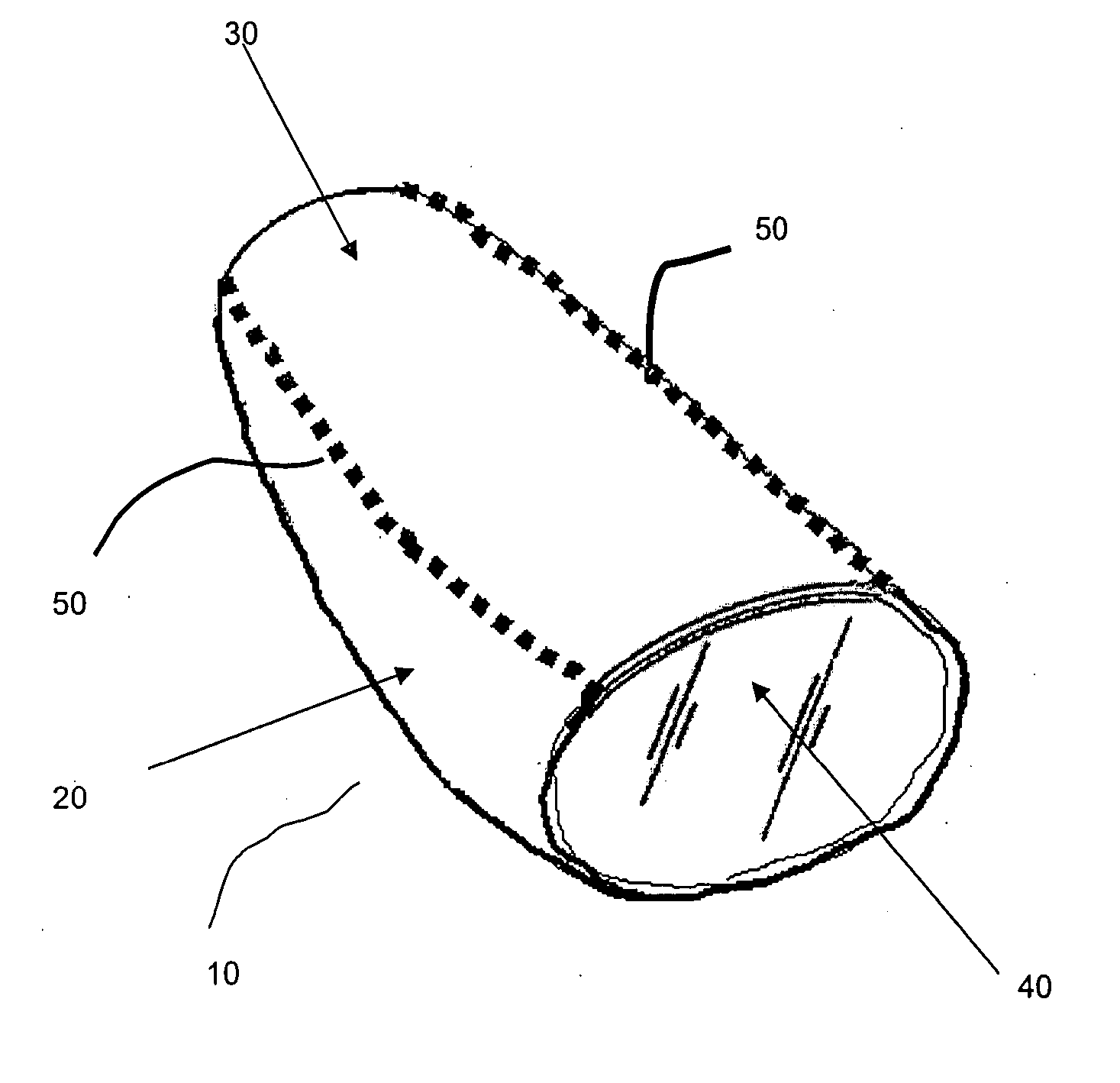

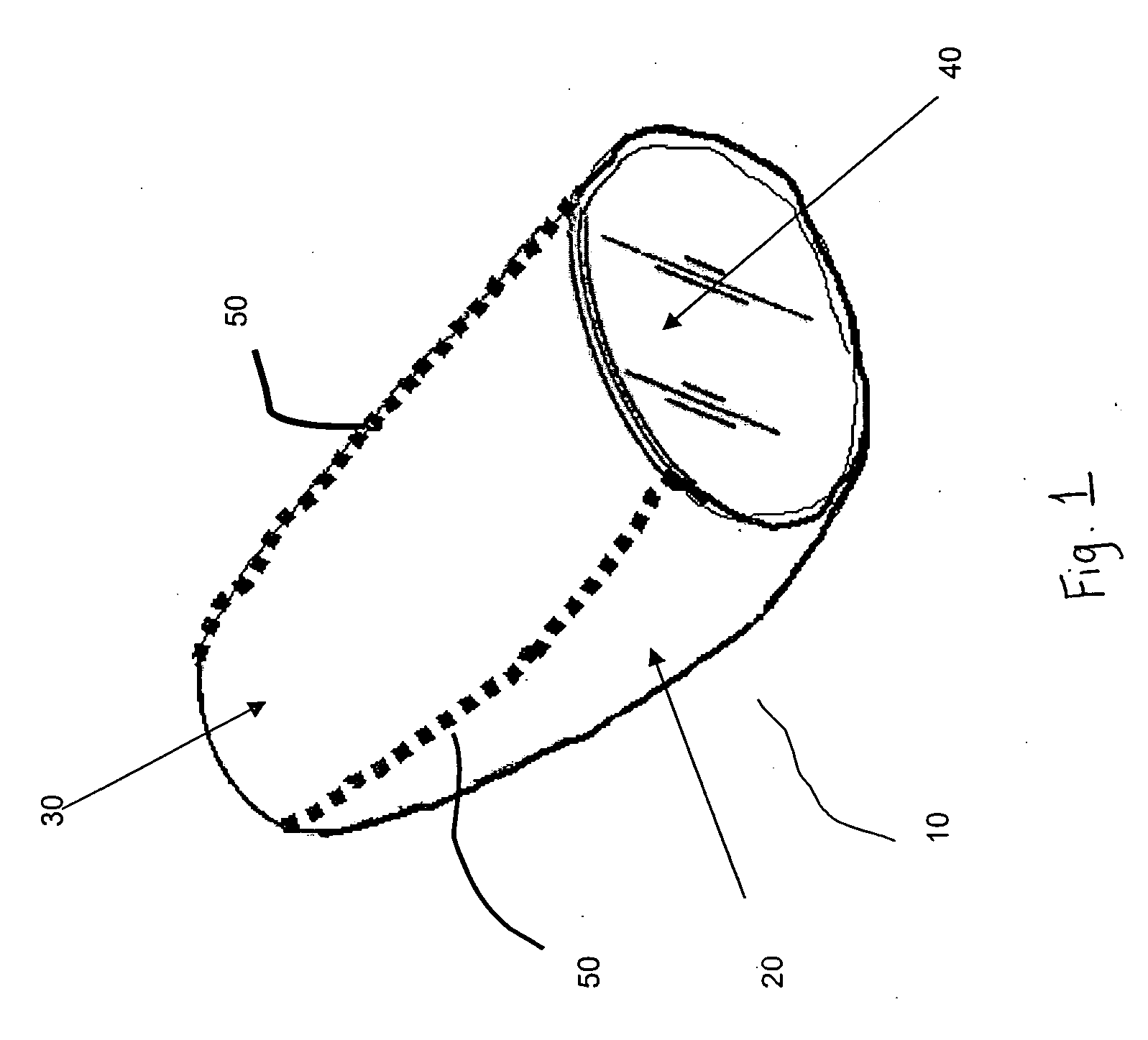

Image

Examples

example 1

[0094] A 3-D finger glove was formed as follows.

[0095] A first section made from a point un-bonded spunbond laminate material was ultrasonically welded to a stretch-bonded laminate (SBL) sheet using a Branson 920 IW ultrasonic welder. The point un-bonded spunbond laminate formed the front of the finger glove, while the SBL sheet formed the back of the finger glove.

[0096] The point un-bonded spunbond laminate was formed by thermally bonding together a polypropylene spunbond web, a breathable film sheet, and a bicomponent spunbond web. The breathable film sheet was placed in between the spunbond webs.

[0097] The polypropylene spunbond web had a basis weight of 17 gsm. The bicomponent spunbond web was made from bicomponent filaments having a polyethylene component and a polypropylene component in a side-by-side relationship. The bicomponent spunbond web had a basis weight of 84.8 gsm. The breathable film sheet was made from a linear low density polyethylene containing calcium carbona...

example 2

[0101] A 3-D finger glove as described in Example 1 was constructed. In this example, however, the bicomponent spunbond sheet of the point un-bonded spunbond laminate had a basis weight of 122 gsm. During the point un-bonded process, the top bond roll was heated to 132° C., while the bottom bond roll was heated to 115.5° C. The SBL was stretched by 35 percent while the layers were bonded together. After being formed, the finger glove was treated with peppermint oil. The finger glove was then subsequently used to clean the mouth of an adult.

example 3

[0102] A 3-D finger glove was constructed similar to the finger glove described in Example 1, however, the bicomponent spunbond sheet of the point un-bonded spunbond laminate was a through-air bonded bicomponent fibrous web having a basis weight of 61 gsm. The bicomponent filaments contained a polyethylene component and a polypropylene component in a side-by-side relationship. During the point un-bonded process, the top bond roll was heated to 127° C. while the bottom bond role was heated to 115.5° C. The SBL was stretched by 40 percent while the layers were bonded together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com