Heat exchanger

a technology of heat exchangers and heat exchangers, applied in the field of heat exchangers, can solve the problems of reducing the reliability of such systems, adding cost and complexity to such systems,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

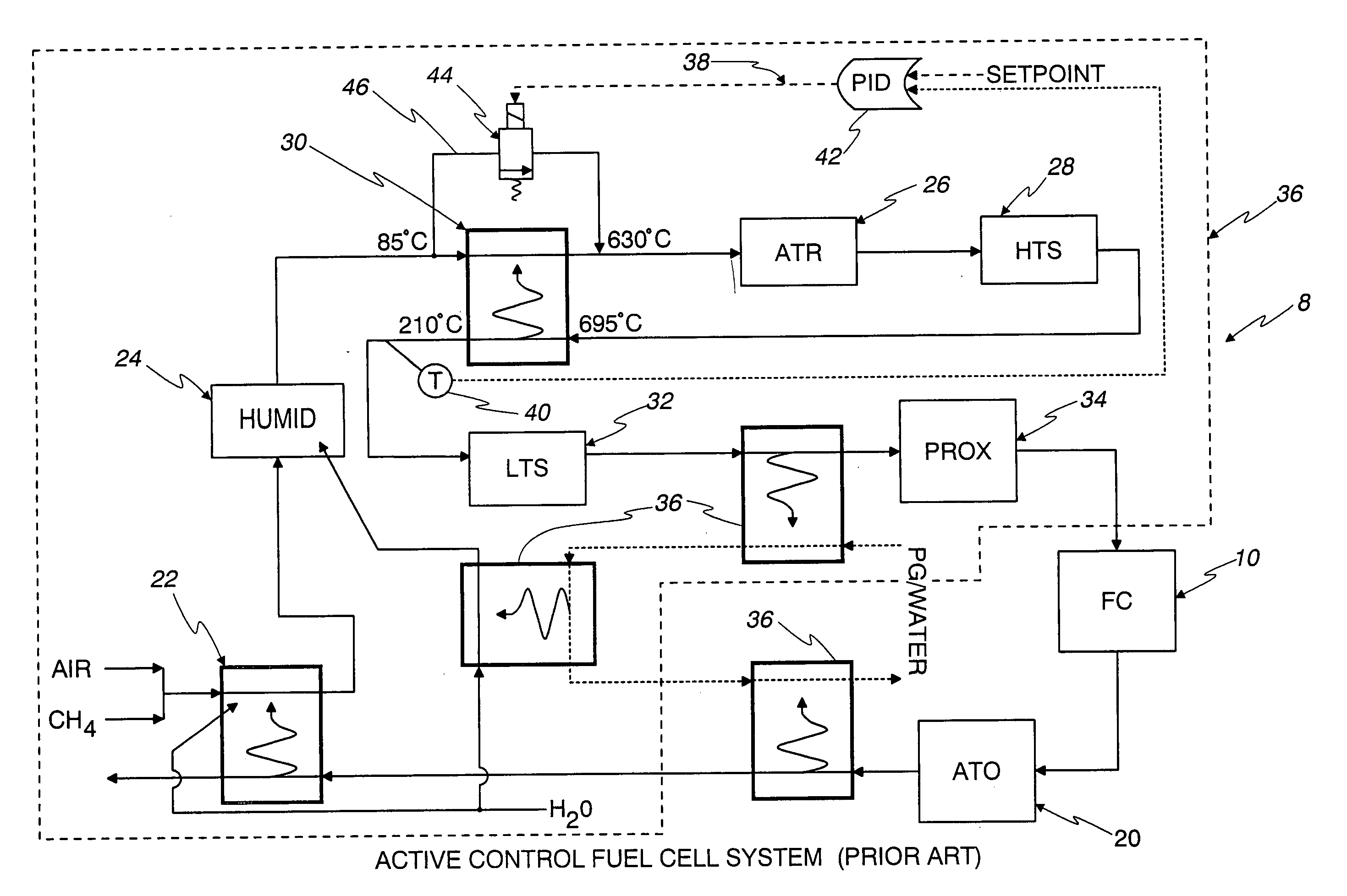

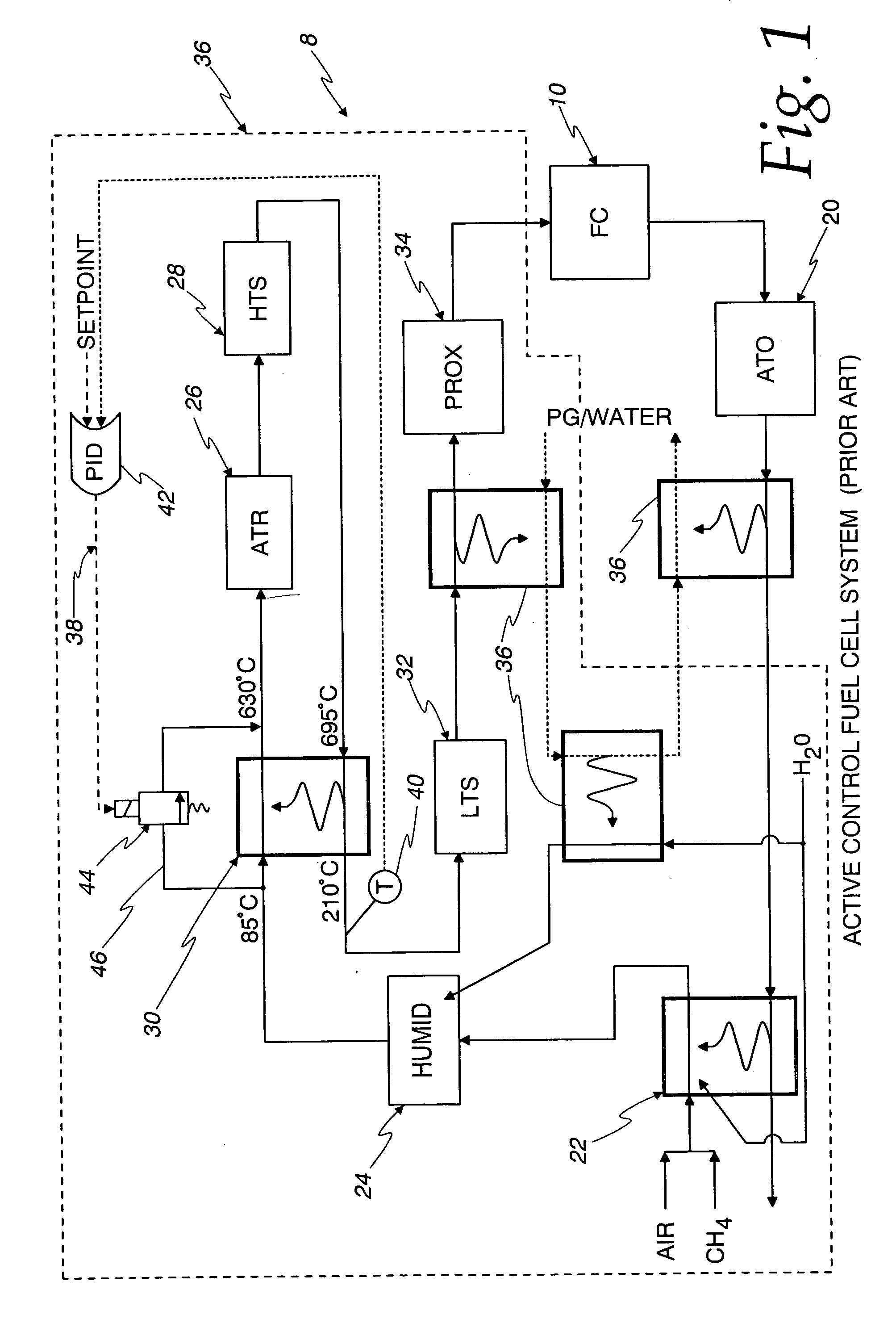

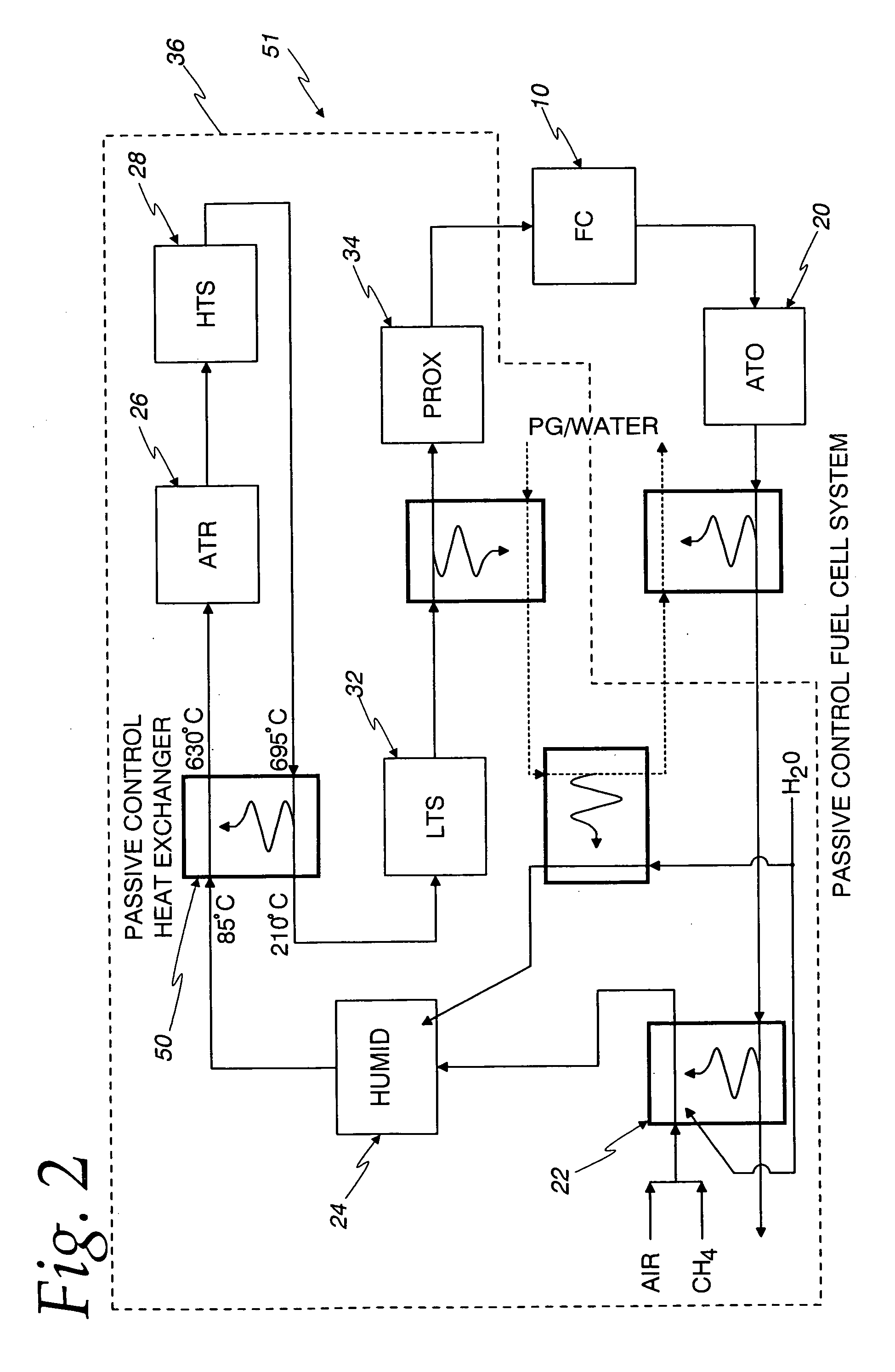

[0043]FIG. 2 shows a heat exchanger 50 embodying the present invention substituted for the recuperative heat exchanger 30 and its control system 38 shown in FIG. 1 in a proton exchange membrane type fuel cell system 51. With the exception of the substitution of the heat exchanger 50 for the heat exchanger 30 and it's control system 38, the fuel cell systems 8 and 51 shown in FIGS. 1 and 2, respectively, are identical and like reference numbers represent like components. While, the heat exchanger 50 made according to the invention is shown in FIG. 2 incorporated in the fuel processing system 36 of the proton exchange membrane type fuel cell system 51, it should be understood that heat exchangers according to the invention can and will find use in other applications. Accordingly, no limitation to use of the heat exchangers according to the invention with fuel cell systems or with particular types of fuel cell systems is intended, unless expressly recited in the claim. For example, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com