Two-circuit grip heater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

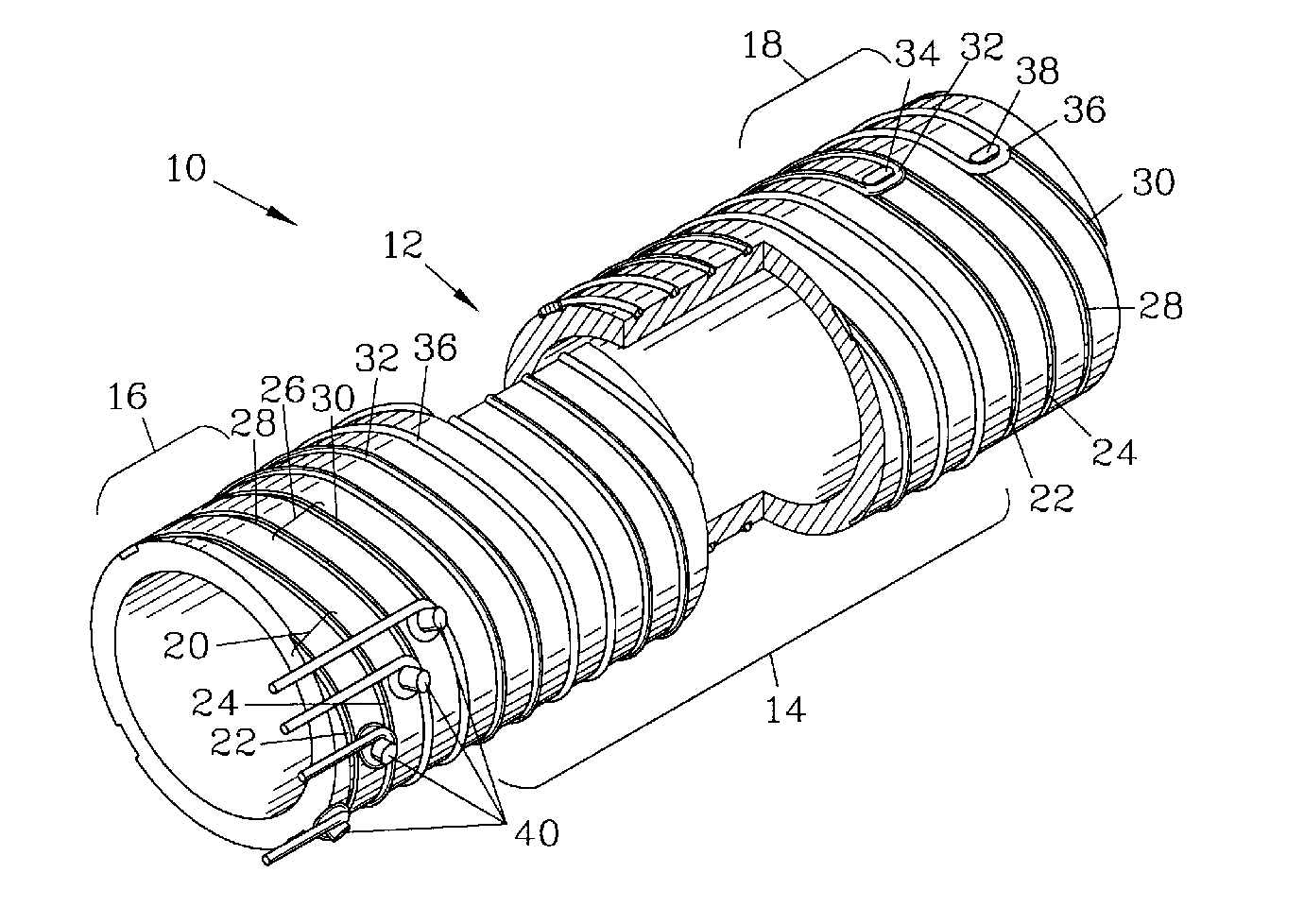

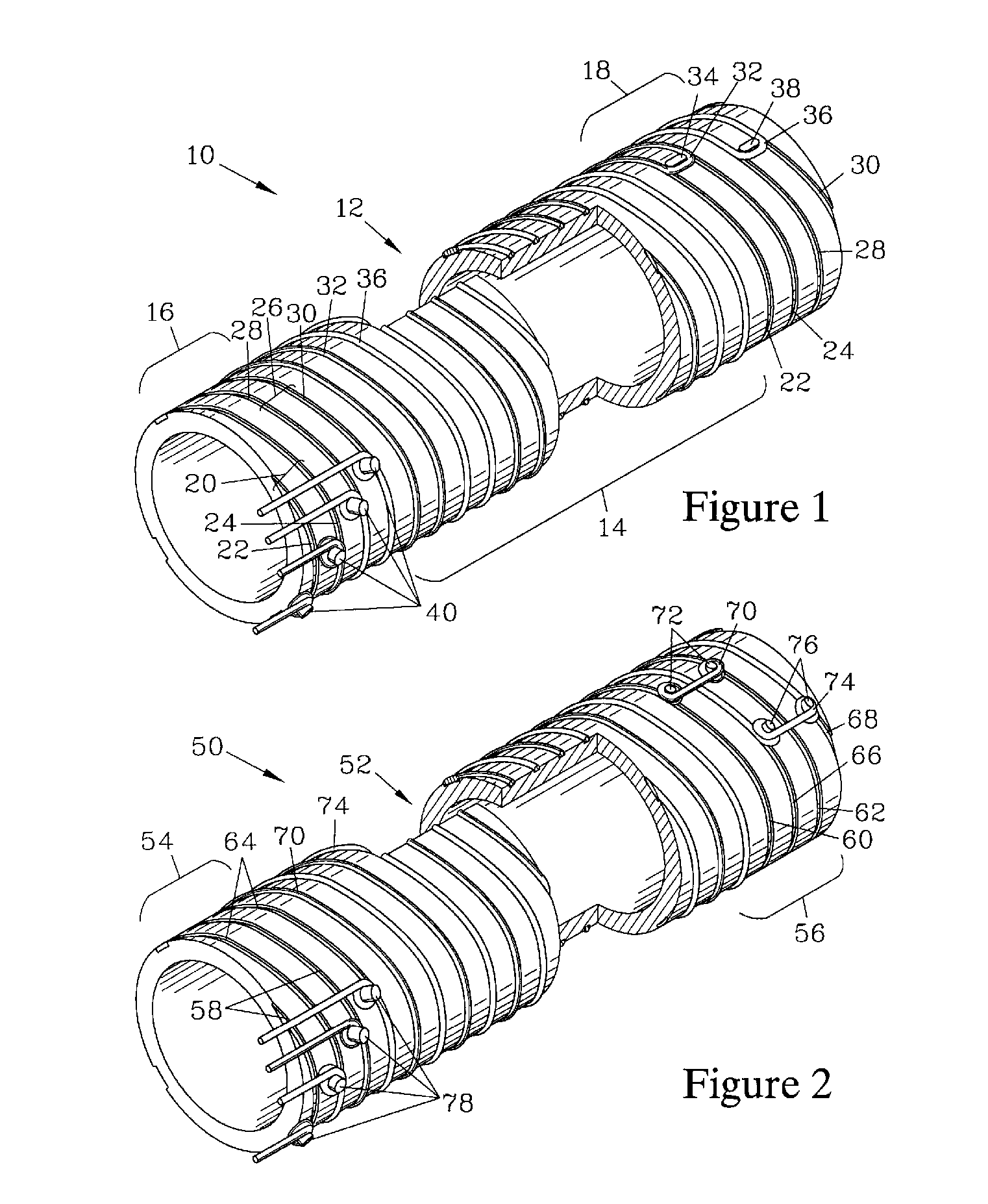

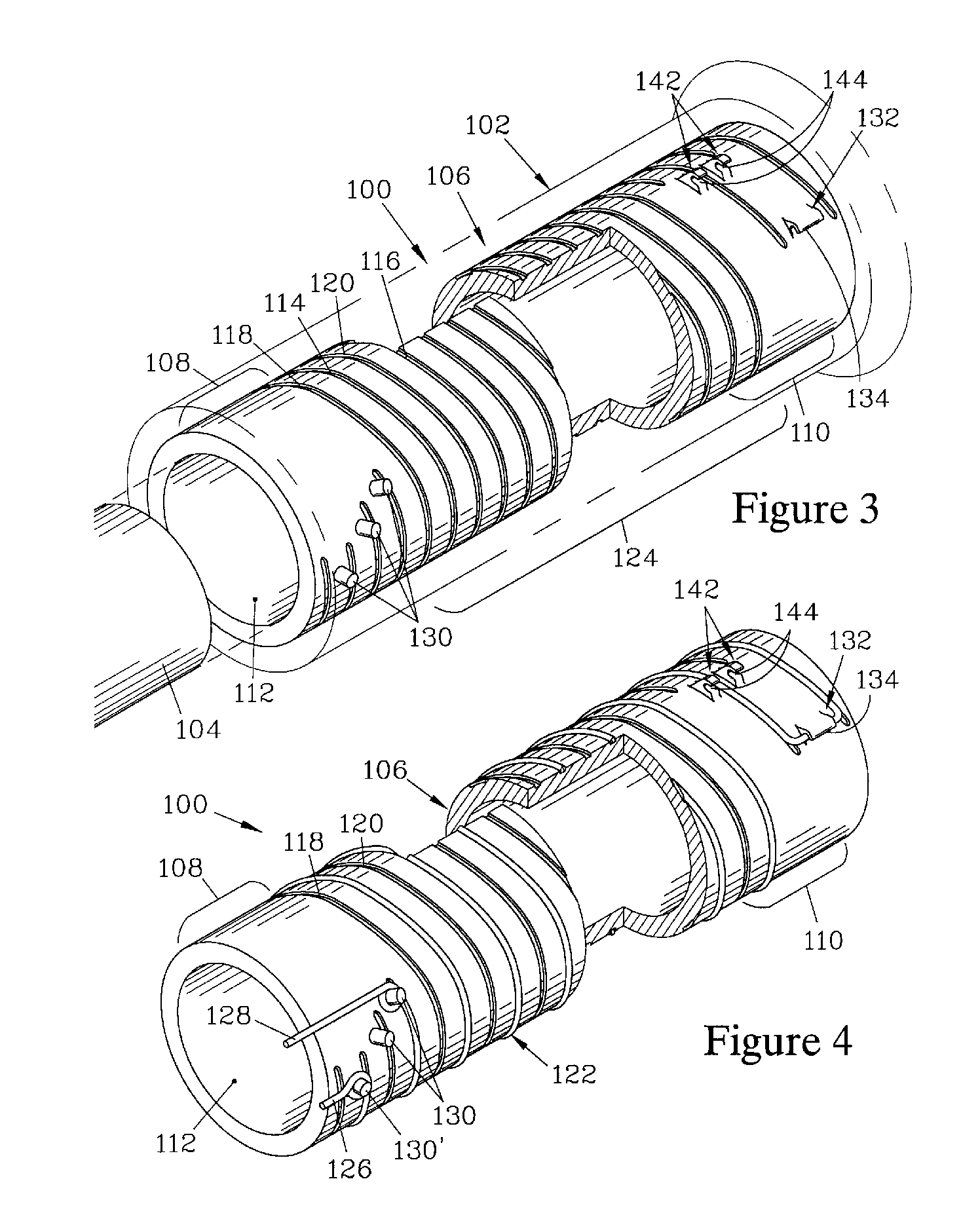

[0025]FIG. 1 is an isometric view of a grip heater 10 that includes a tubular insulator 12 having a central region 14 that terminates in a base end region 16 and a distal end region 18. The tubular insulator 12 has a first pair of recesses 20 which are formed by a first helical groove 22 and a second helical groove 24 which are spaced apart, parallel, and positioned in a side-by-side relationship. A second pair of recesses 26 are provided, which are formed by a third helical groove 28 and a fourth helical groove 30 which are also spaced apart, parallel and in a side-by-side relationship. In this embodiment, the two pairs of recesses (20, 26) are in a side-by-side relationship and do not overlap.

[0026] A first heating element 32 resides in the first helical groove 22 and the second helical groove 24 along the central region 14. The first heating element 32 traverses the first helical groove 22 from the base end region 16 and to the distal end region 18, where it passes around a dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com