Method and apparatus for manufacturing three-dimensional objects

a three-dimensional object and manufacturing method technology, applied in the direction of additive manufacturing, process efficiency improvement, additive manufacturing apparatus, etc., can solve the problems of requiring additional processing time and cost for the removal step, and the outer surface of the three-dimensional object may not be smooth and accurate, so as to prevent unnecessary powder particle deposition, reduce the effect of forming accuracy and intensive heat of the target powder particl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

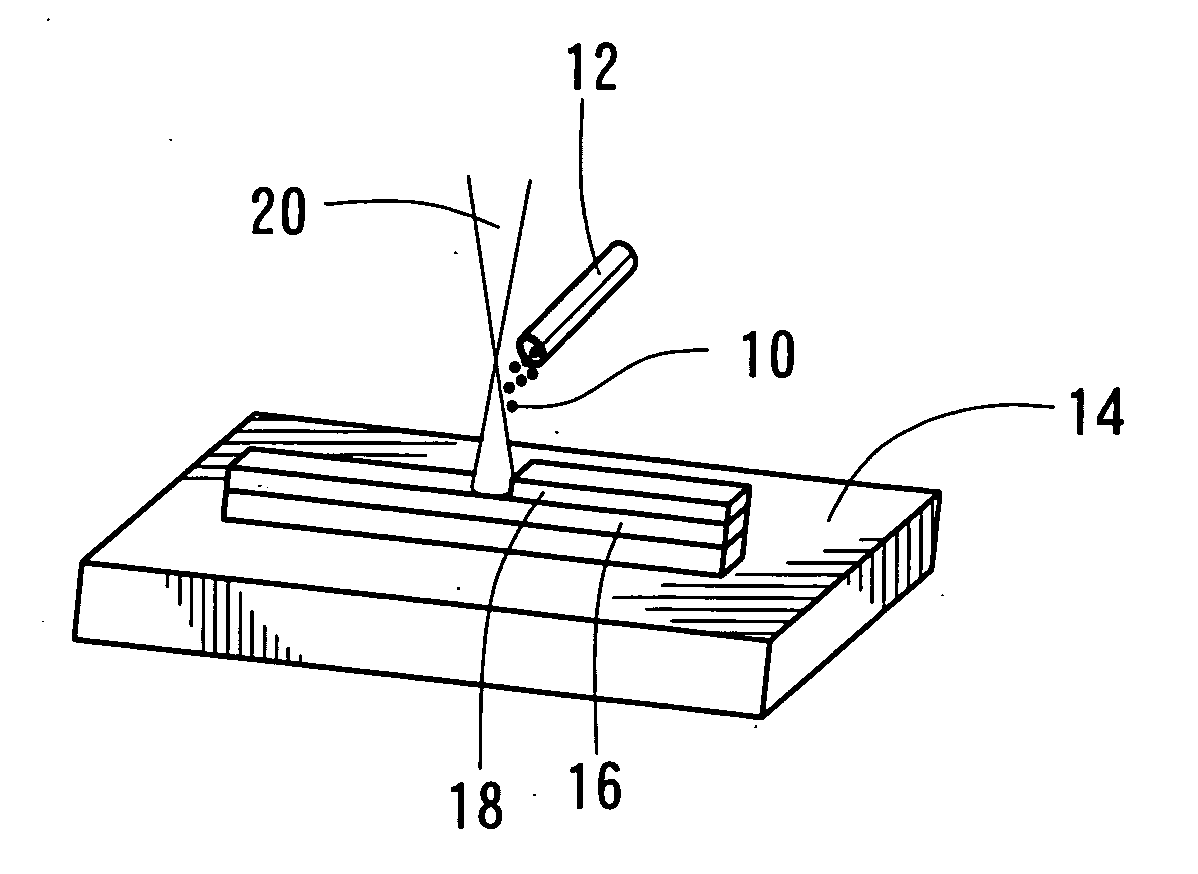

[0055] A more specific embodiment of the present invention will be described below. In this representative embodiment, a Model PF-01 disc-type powder feeder, available from Nihon Welding Rod Co., Ltd., Japan, was used as the powder particle supplying device. A Model 2012H CO2 laser having a 50C oscillator, a rated power of 5 kW, and an argon shielding gas, available from Mitsubishi Electric Corporation, Japan, was used as the high-density energy heat source. Further, two types of powder particles, as shown in Table 1, are used as the powder particles in this representative embodiment.

TABLE 1Details of Powder ParticlesNo.Type of Powder ParticlesMaterialAverage Particle Diameter1Spherical PowderSUS420 30 μm2Granulated PowderSUS410L200 μm (Granulated from10 μm Powder Particles)

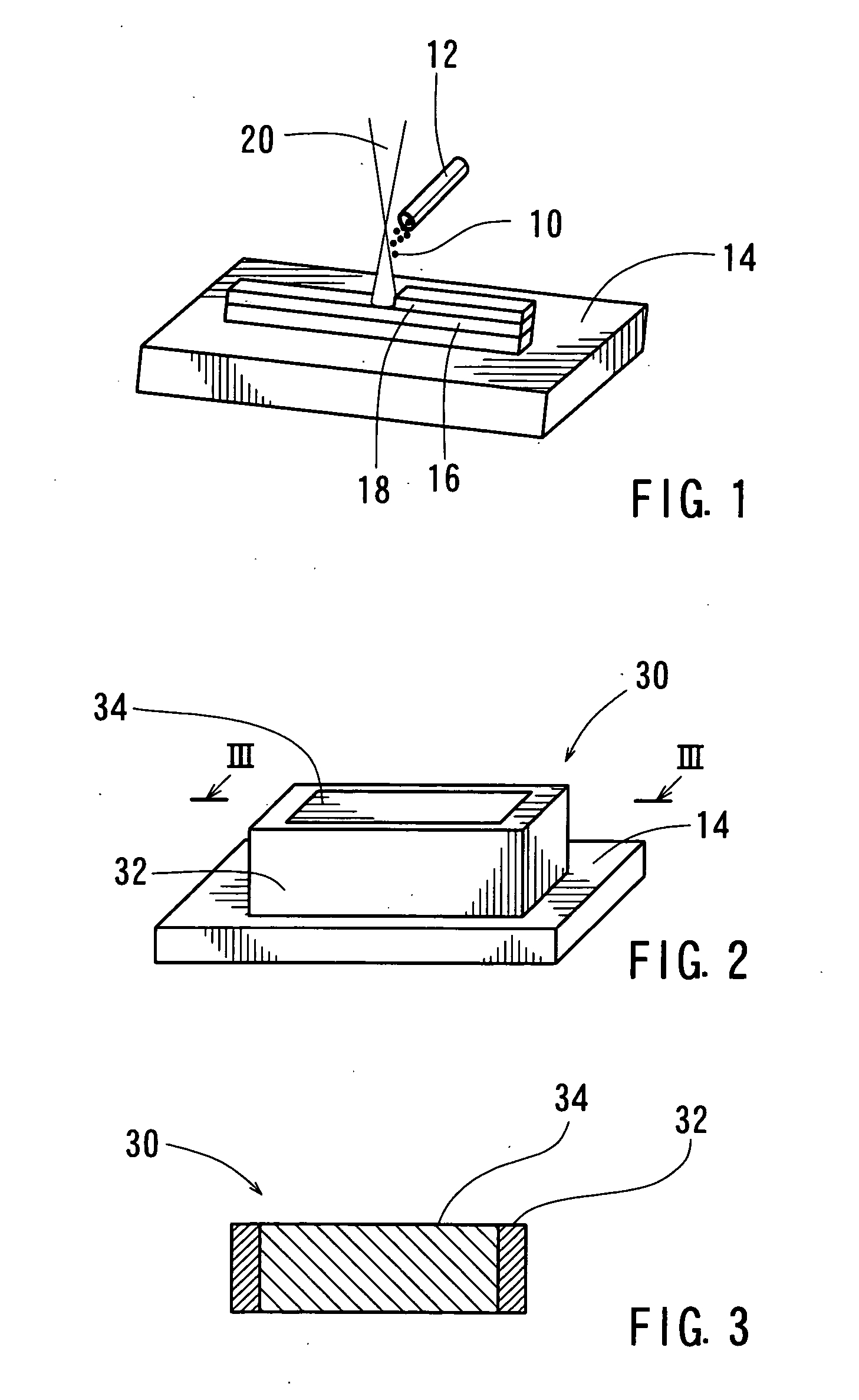

[0056] As shown in FIG. 2, by using the aforementioned devices, a three-dimensional object 30 having an outside dimension of 100 mm×100 mm×100 mm was manufactured. As shown in Table 1, with respect to the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com