Golf ball

a golf ball and multi-piece technology, applied in the field of golf balls, can solve the problems of adversely affecting other important performance characteristics such as rebound, uniform density of balls, and limited design, so as to improve the performance characteristics of balls, improve the rebound characteristics, and maintain the effect of optimal rebound characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

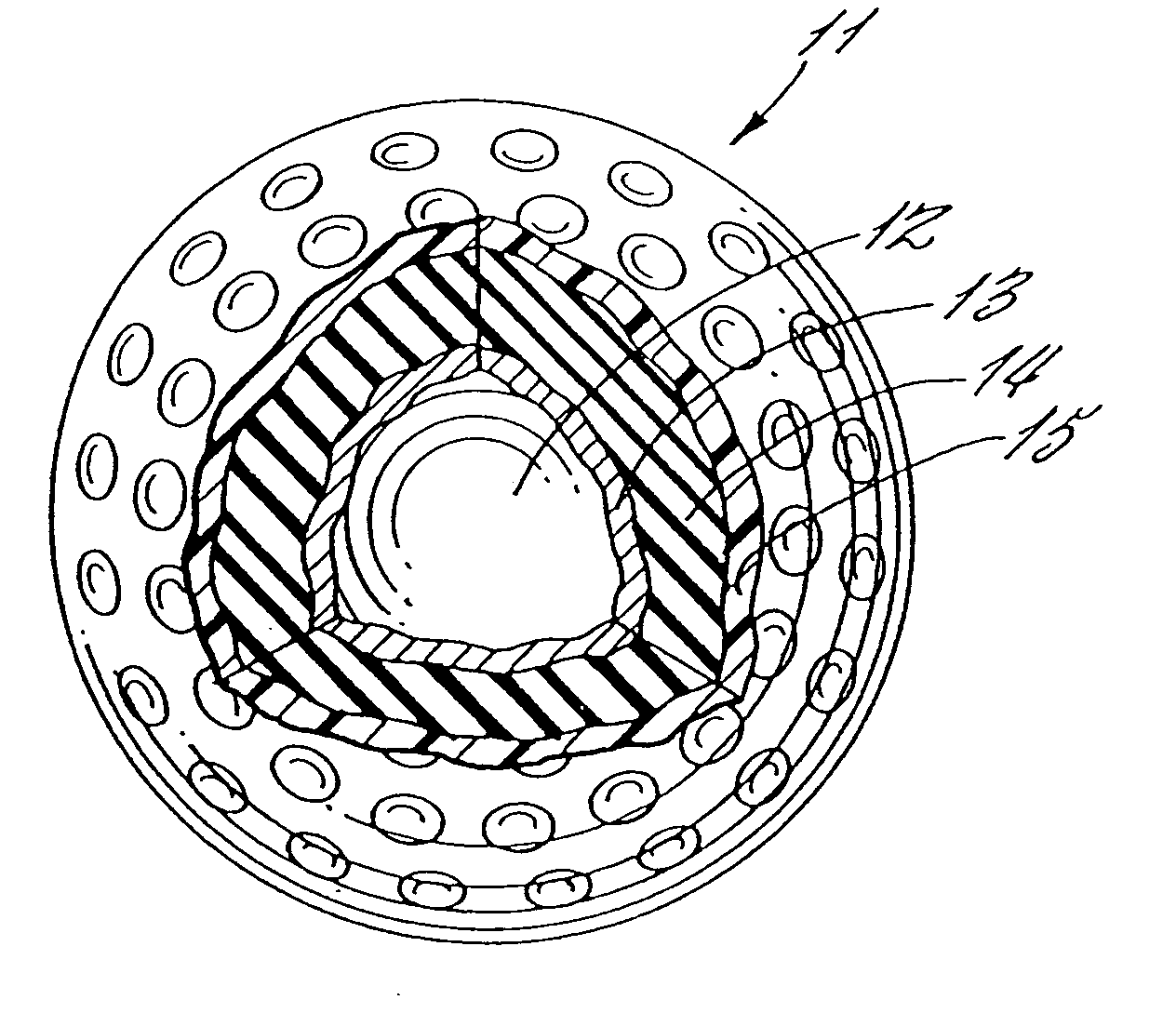

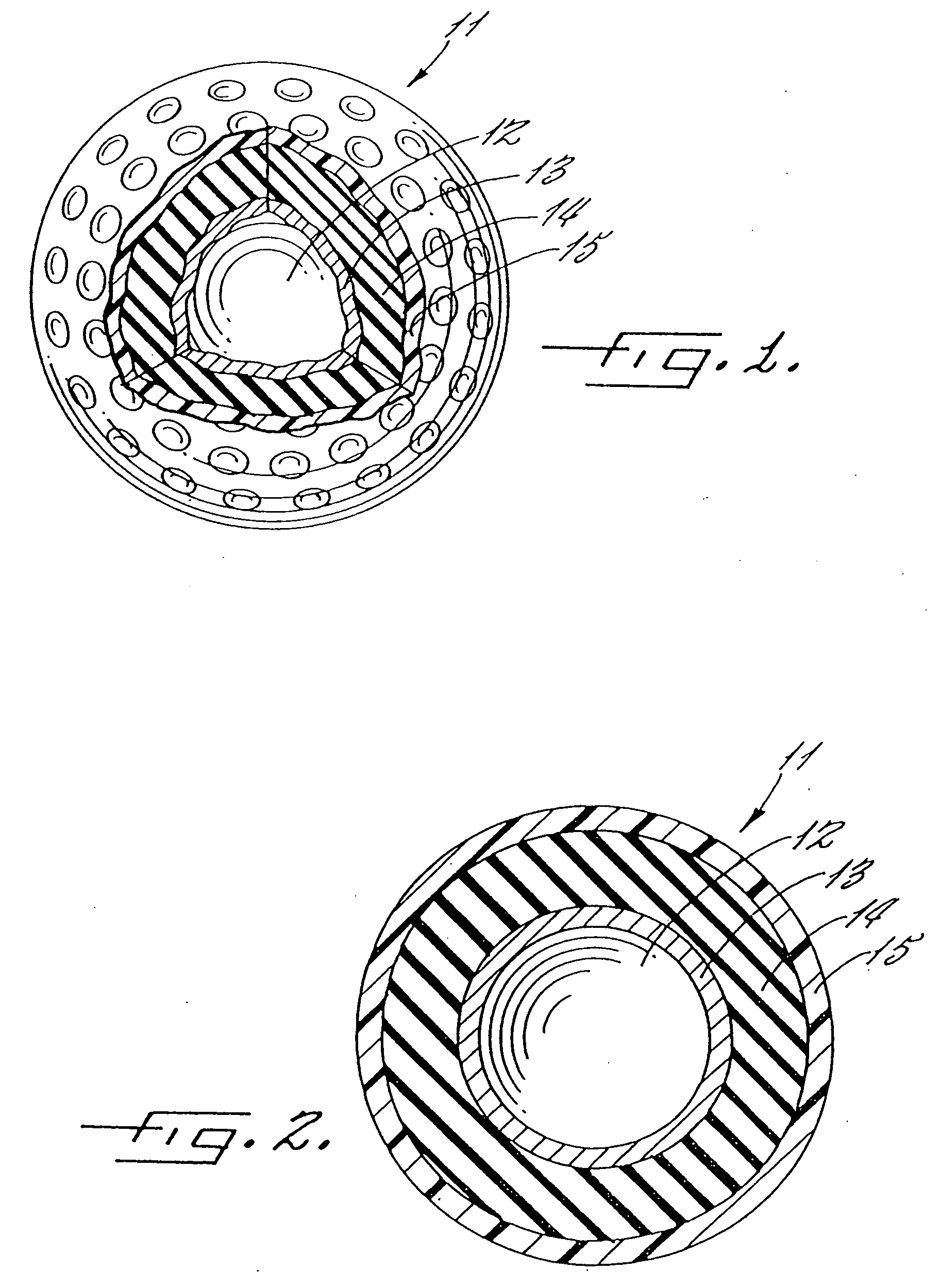

Image

Examples

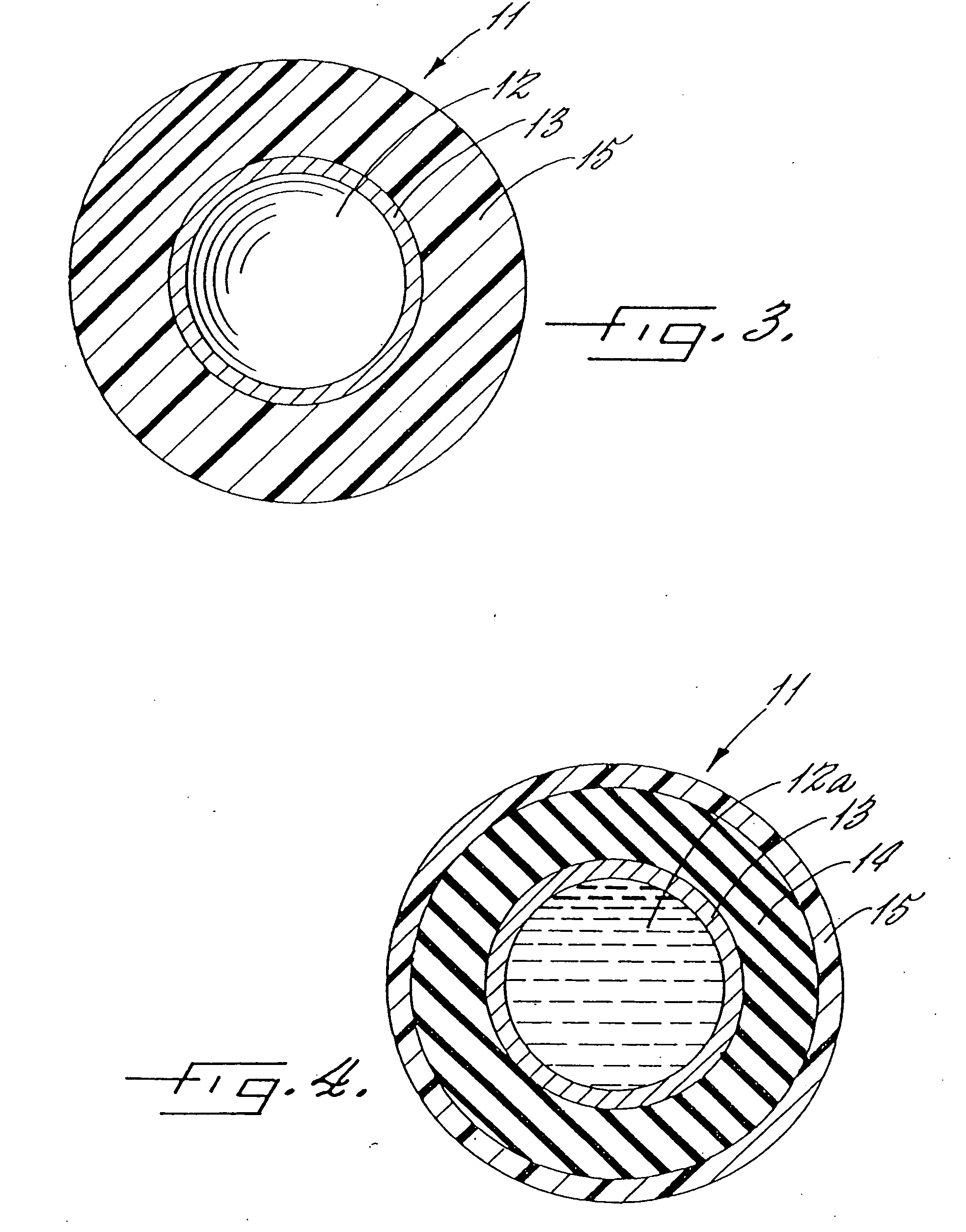

example 1

[0034] Two Piece ball—Titanium core and SURLYN (manufactured by DuPont and registered tradename) cover according to the following specifications:

[0035] A hollow sphere comprising a titanium shell with an inside diameter of 1.374 inches (3.490 centimeters), outside diameter of 1.521 inches (3.863 centimeters), and a mass of 1.258 ounces (35.69 grams).

[0036] SURLYN cover with a density of 58.68 lb / ft.sup.3 (0.95 grams / cm3), an inside diameter of 1.521 inches (3.863 centimeters), an outside diameter of 1.680 inches (4.267 centimeters) and a mass of 0.3514 ounces (9.962 grams). The residual gas in the core does not contribute significantly to the mass of the ball. The total mass of the ball is 1.610 ounces (45.65 grams). The moment of inertia of the ball of Example 1 is about 34 percent greater than a typical two-piece ball.

example 2

[0037] Three piece ball—Titanium core, second layer of polybutadiene, and a SURLYN cover:

[0038] A hollow sphere comprising a titanium shell with an inside diameter of 0.992 inches (2.52 centimeters) and an outside diameter of 1.102 inches (2.80 centimeters), a specific gravity of 4.5 and a mass of 0.494 ounces (14.0 grams).

[0039] Polybutadiene (specific gravity=1.15) with a layer thickness of 0.210 inches (0.53 centimeters) and a mass of 0.762 ounces (21.61 grams).

[0040] SURLYN (specific gravity=0.95) cover of thickness 0.0787 inches (0.2 centimeters), and a mass of 0.348 ounces (9.87 grams).

[0041] The residual gas inside the core does not contribute significantly to the mass of the ball. The total mass of the ball is 1.604 ounces (45.5 grams). The moment of inertia of the ball of Example 2 is about six percent greater than a typical two-piece ball.

[0042] As described above, the improved golf ball of the present invention provides improved performance characteristics including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com