Centrifugal pump with swirl sprayer engine directly connected with high-speed function vane wheel and even-spinning labyrinth

A direct-connected, swirl-nozzle technology for machines/engines, liquid fuel engines, components of pumping devices for elastic fluids, etc., and can solve problems such as high axial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

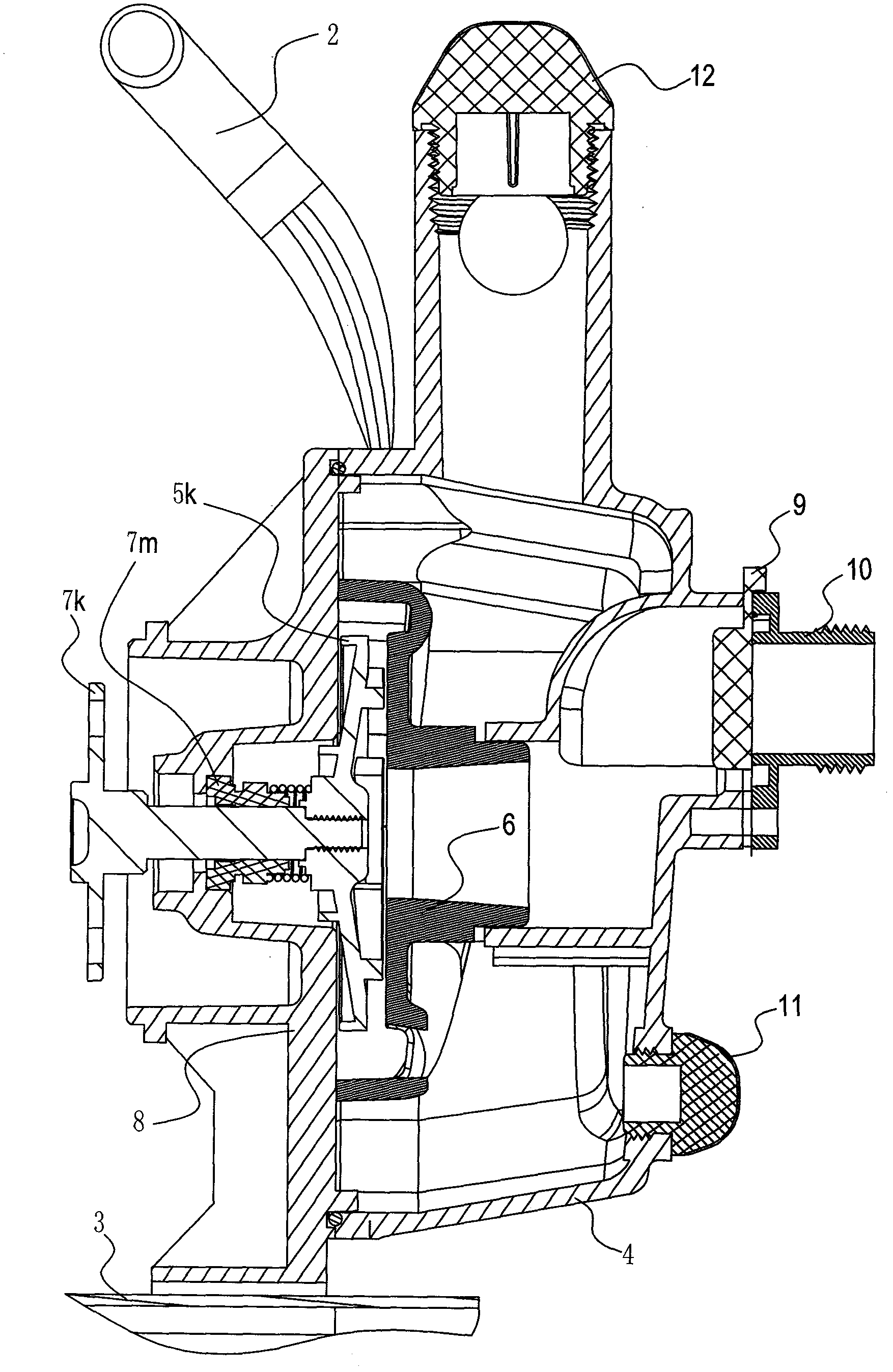

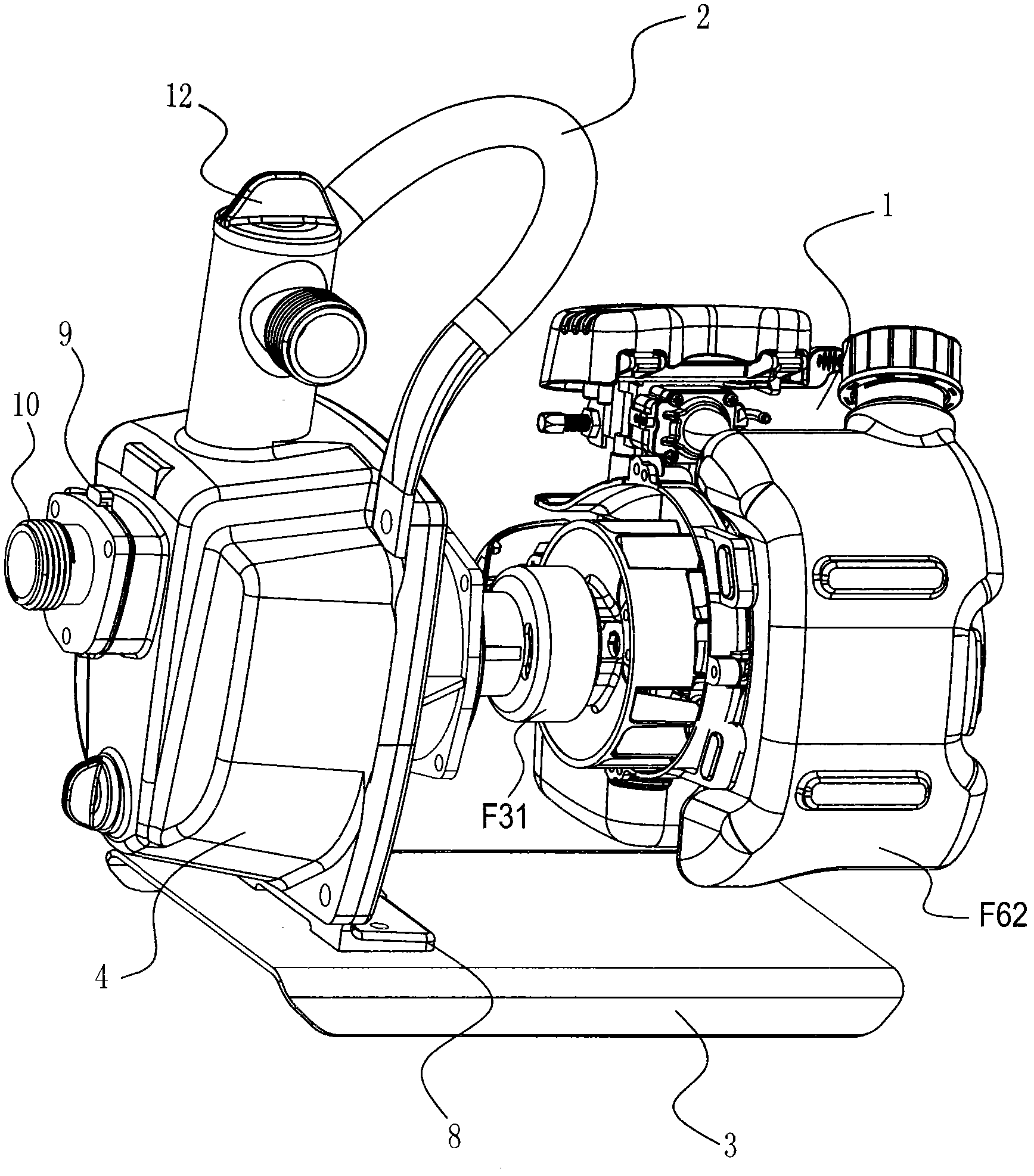

Embodiment Construction

[0070] In order to compensate for the loud noise caused by the existing mechanism of the pump, an improved alumina-containing catalase muffler tube for engines provided by the present invention is installed in the machine, so that the exhaust gas passes through the muffler assembly and The catalyst muffler pipe (69) is then discharged from the gap or small hole gap through the entire protective cover that covers the pump with muffling effect. The whole centrifugal pump, or the protective cover together with the engine, or double-layer blow-molded shell, lined with foam plastic, or other materials.

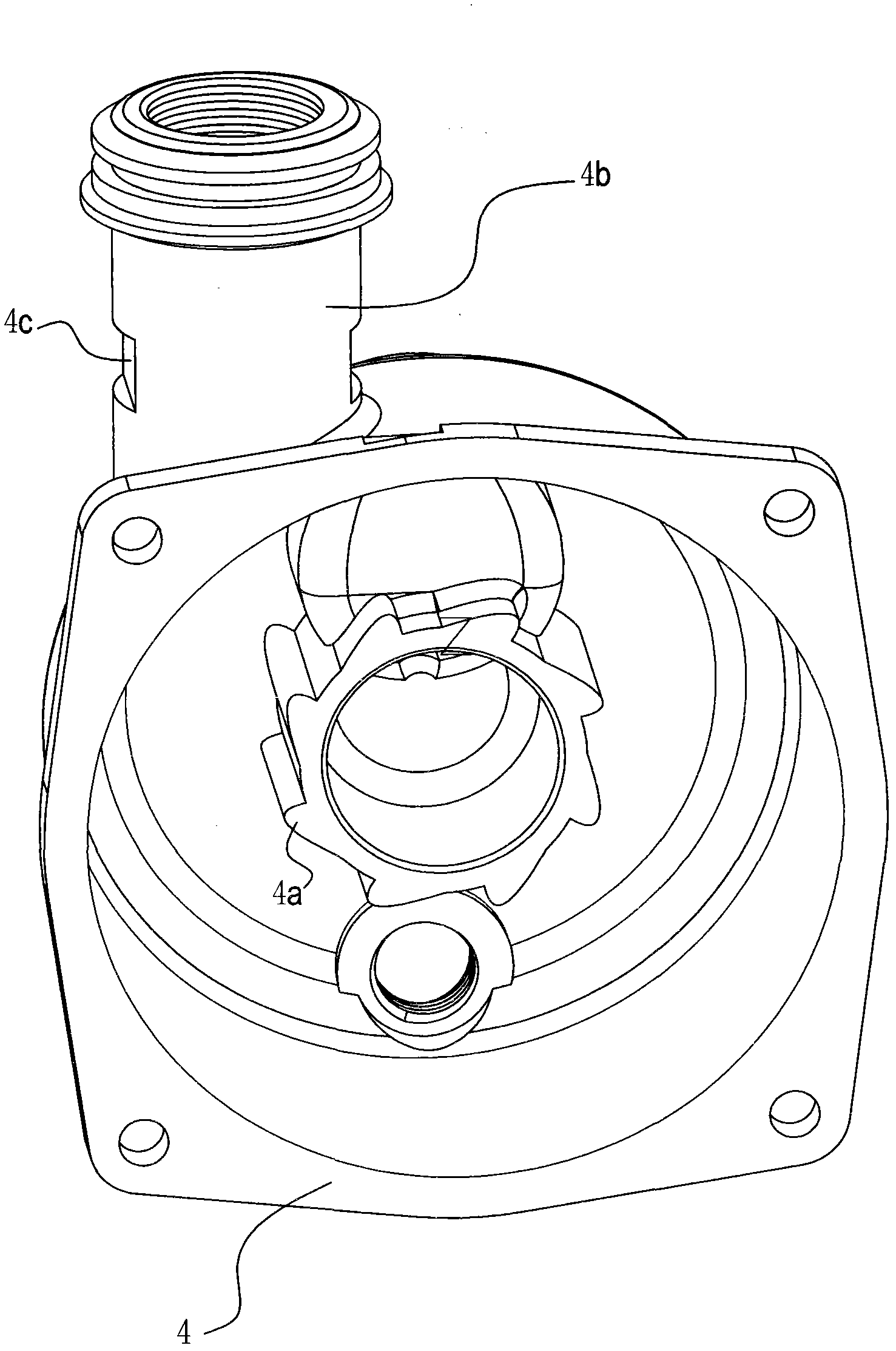

[0071] Before starting the centrifugal pump, the pump casing must be filled with water before it can be started, otherwise the pump body will not be able to complete the suction, which will cause the pump body to heat and vibrate. If no water is discharged, it will run dry, forming an air trap and causing damage to the pump. accident.

[0072] Because the present invention relates to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com