Lubricant dispenser

a technology of lubricant dispenser and dispenser body, which is applied in the direction of engine lubrication, liquid/fluent solid measurement, volume measurement, etc., can solve the problems of complicated protective measures, complicated gas cell production, and harm to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

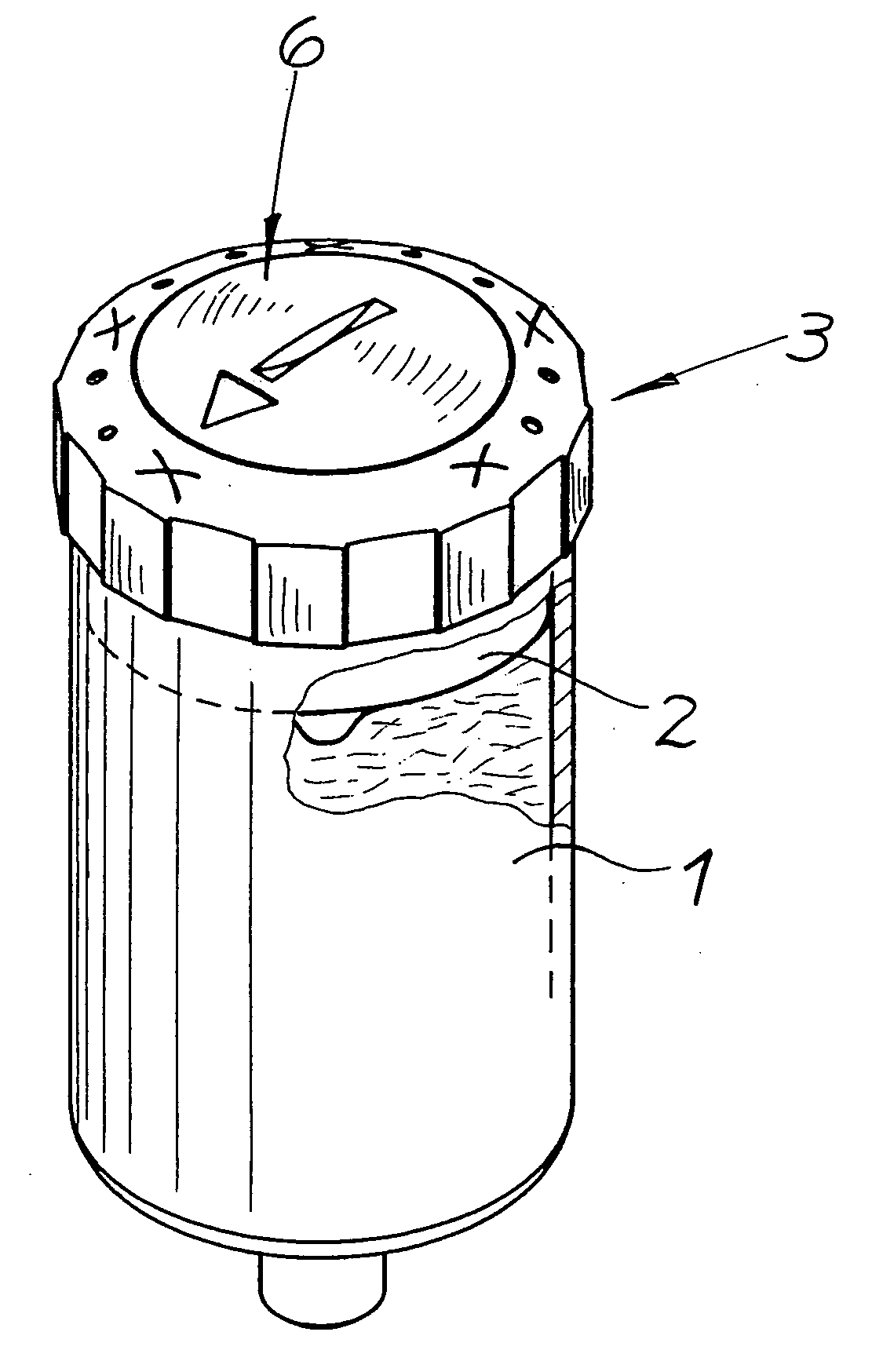

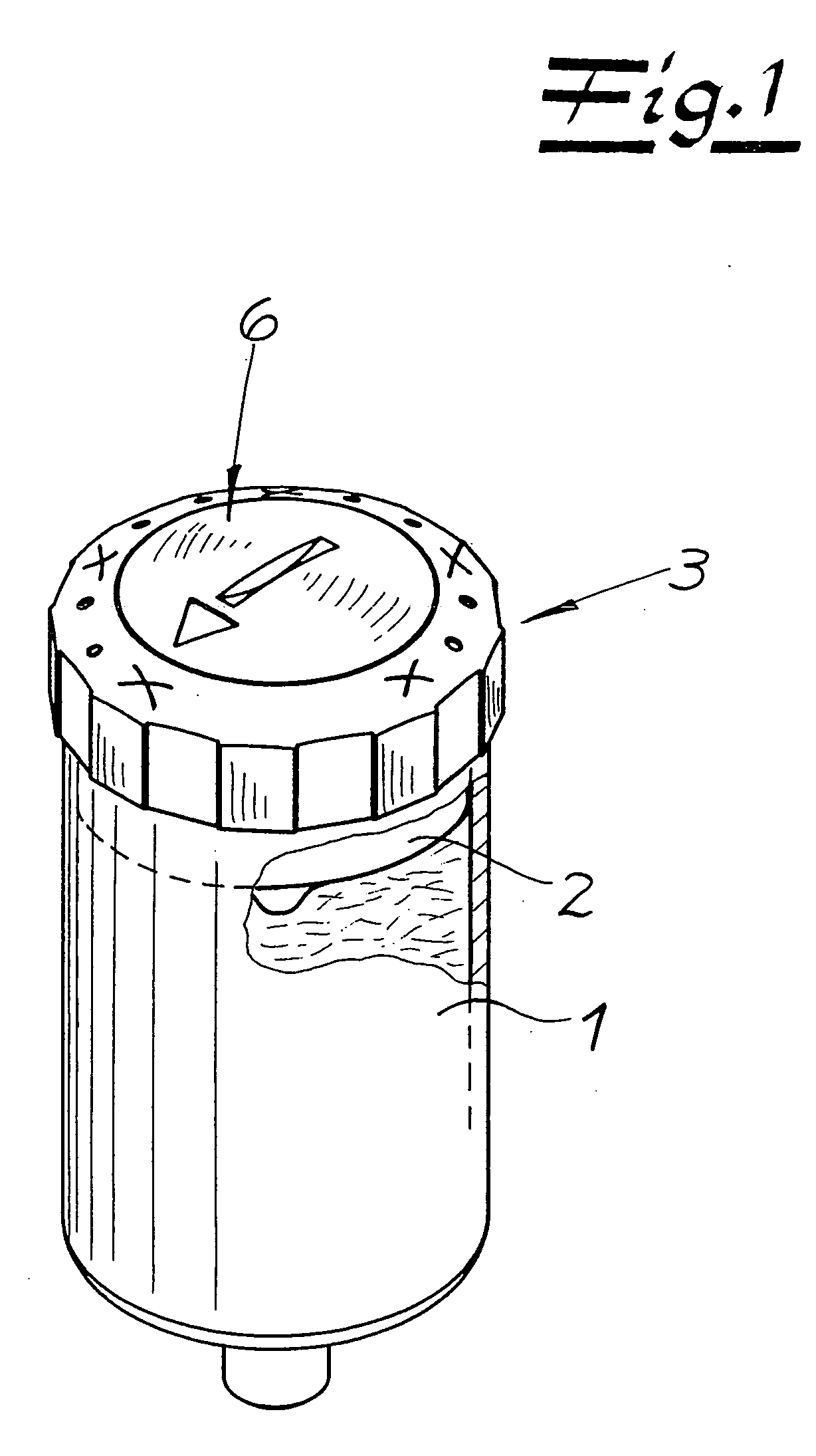

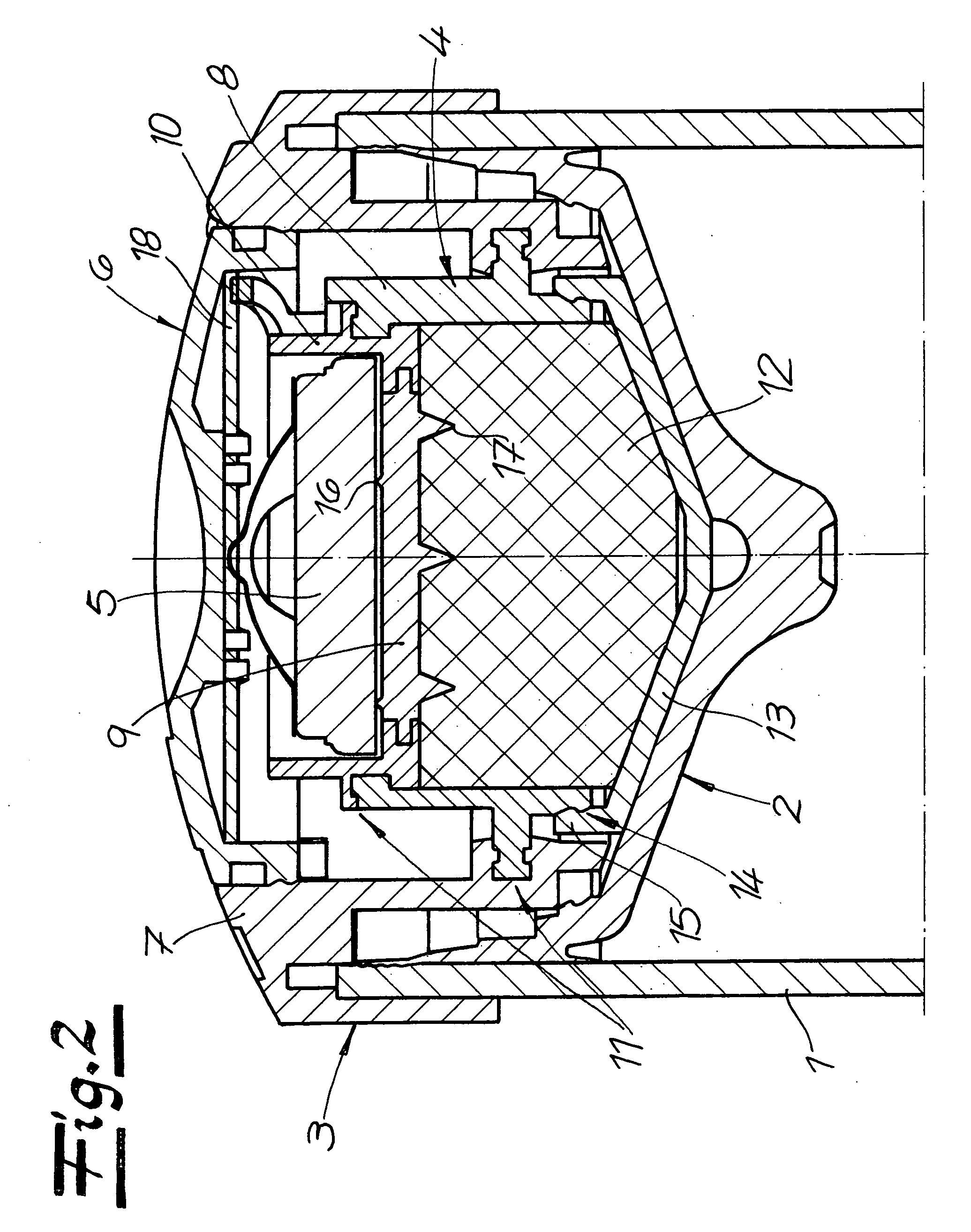

[0018] The fundamental structure of the lubricant dispenser shown in the drawings includes a lubricant container 1 that has an outlet opening for lubricant, a piston 2 disposed on the lubricant container 1, and a cap 3 connected with the lubricant container, having a device for generating a gas that impacts the piston. The device for gas generation has a gas cell 4 with an electrolyte fluid and electrodes for electrochemical gas generation, a power source 5 in the form of a button battery, as well as an electrical connection between the power source and the electrodes with a switch 6.

[0019] As particularly evident from FIG. 2, cap 3 is a plastic injection-molded part produced in one piece, formed from several parts, using the multi-component injection-molding method. This part is made up of an outer ring 7 made of insulation material and an insert that forms gas cell 4, having two electrically conductive wall regions 8, 9 electrodes, as well as having an intermediate piece 10 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com