Open bottom fiber reinforced precast concrete arch unit

a precast concrete and open-bottom technology, applied in mining structures, tunnel linings, constructions, etc., can solve the problems of substantial additional time and labor required to assemble and connect sections at the site, and achieve the effect of reducing the volume and weight of concrete, reducing labor costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

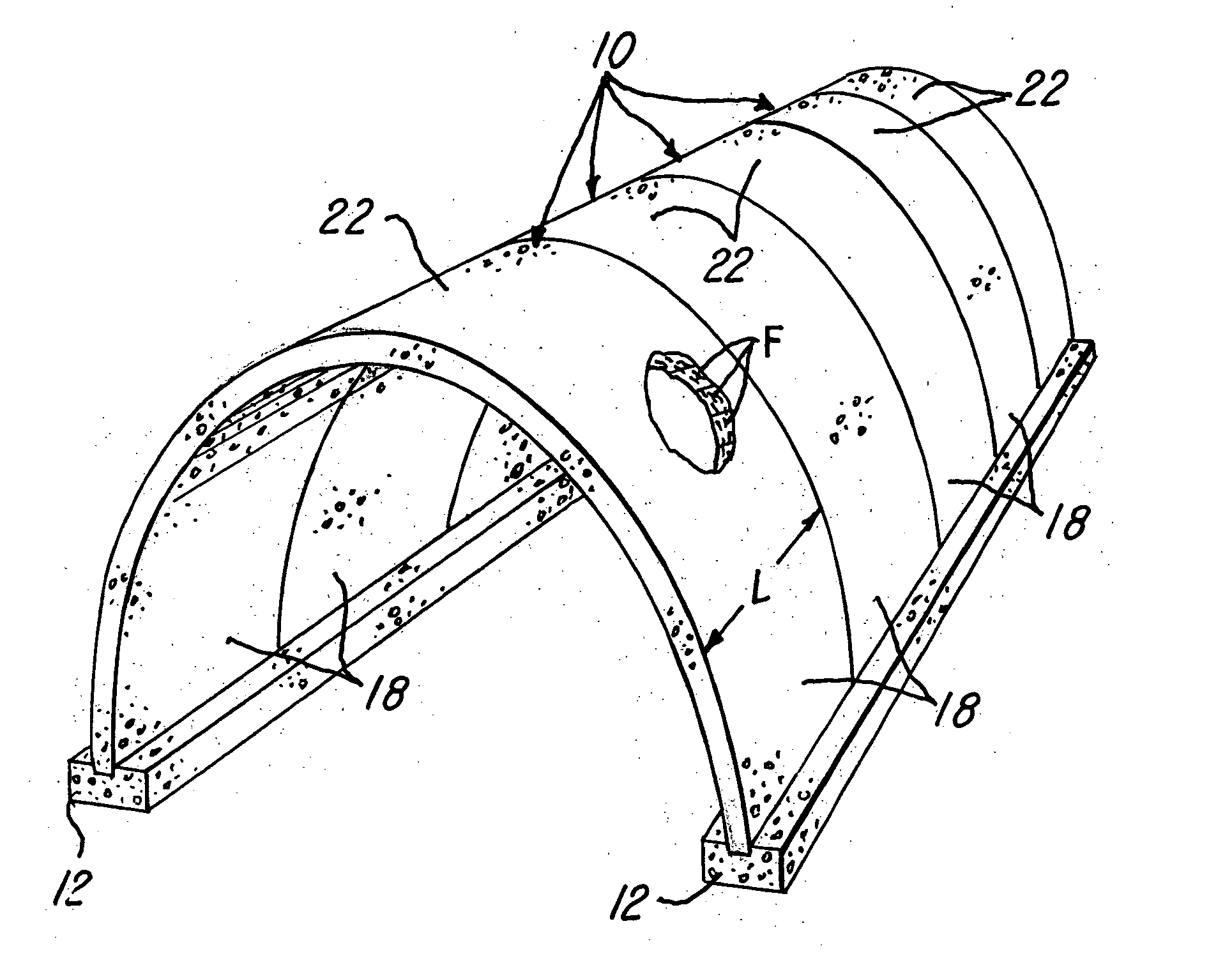

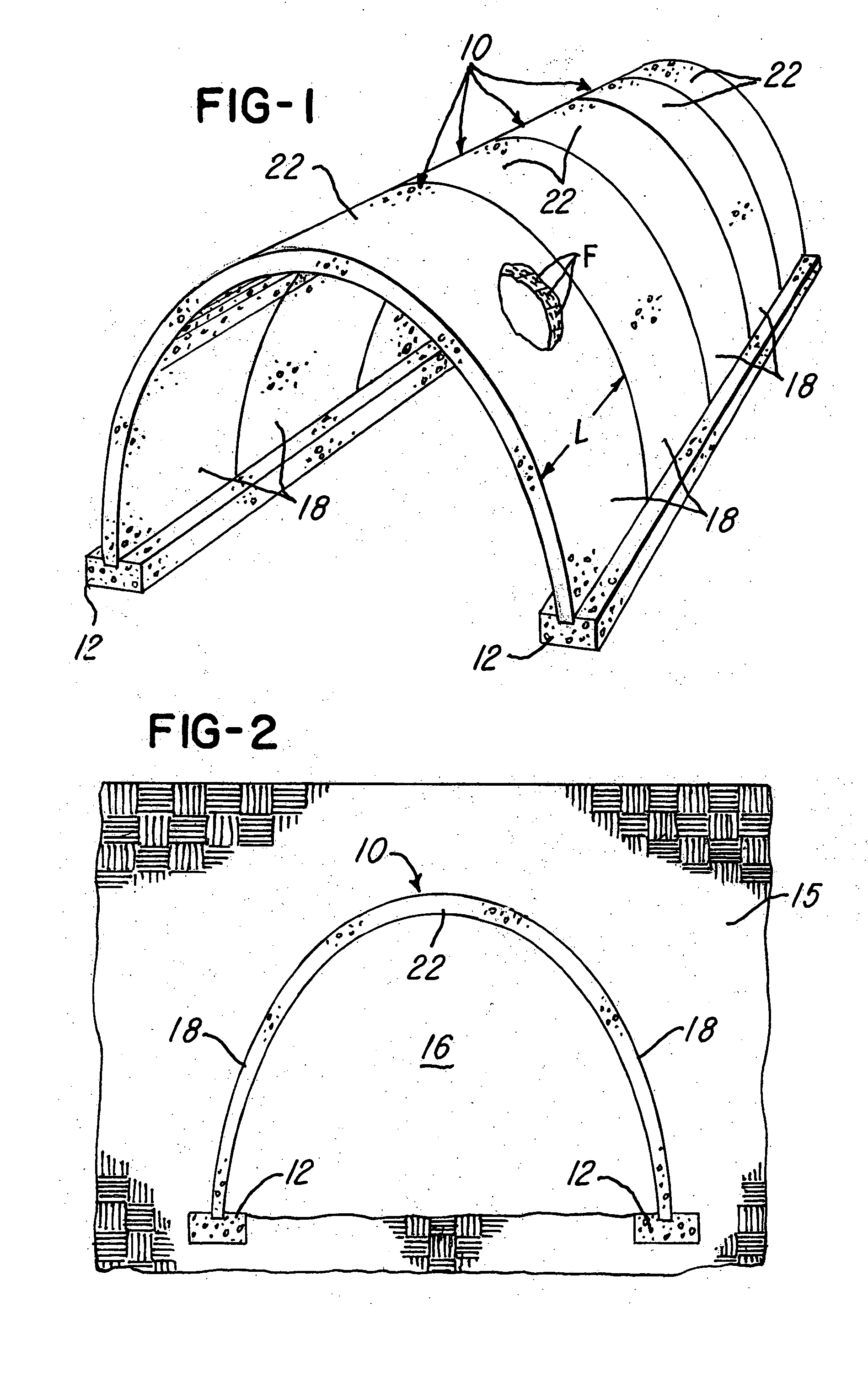

[0012]FIG. 1 illustrates a plurality or series of longitudinally aligned one-piece open bottom fiber reinforced precast concrete arch units 10 constructed in accordance with the invention and supported by parallel spaced elongated concrete footers 12 which may be cast in place at the construction site or be part of a poured concrete floor. The arch units 10 are buried in compacted soil 15 (FIG. 2) and define a passage 16 through which pedestrians, vehicles or water may pass. The arch units may also be provided with end walls to define a chamber in which water may be temporarily stored, for example, run-off water received from a large parking lot.

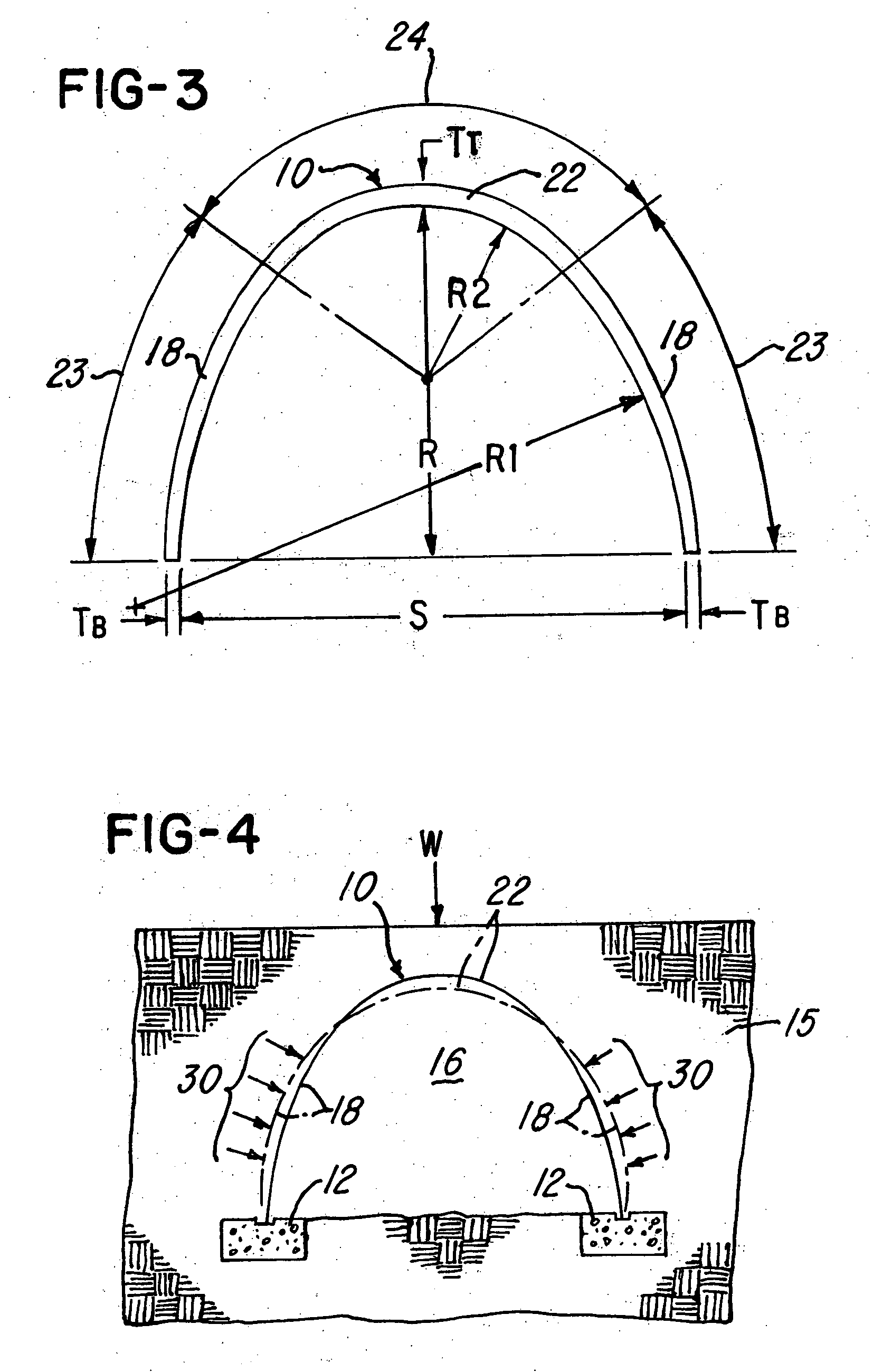

[0013] Referring to FIGS. 1 & 3, each of the precast concrete arch units 10 has a length L, for example, eight feet, and includes a pair of curved or arcuate opposite legs or side wall portions 18 integrally connected by a curved or arcuate top wall portion 22, and the arcuate length of each portion 18 and 22 may be generally the same, as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com