Gloves with enhanced anti-cuff-slip surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

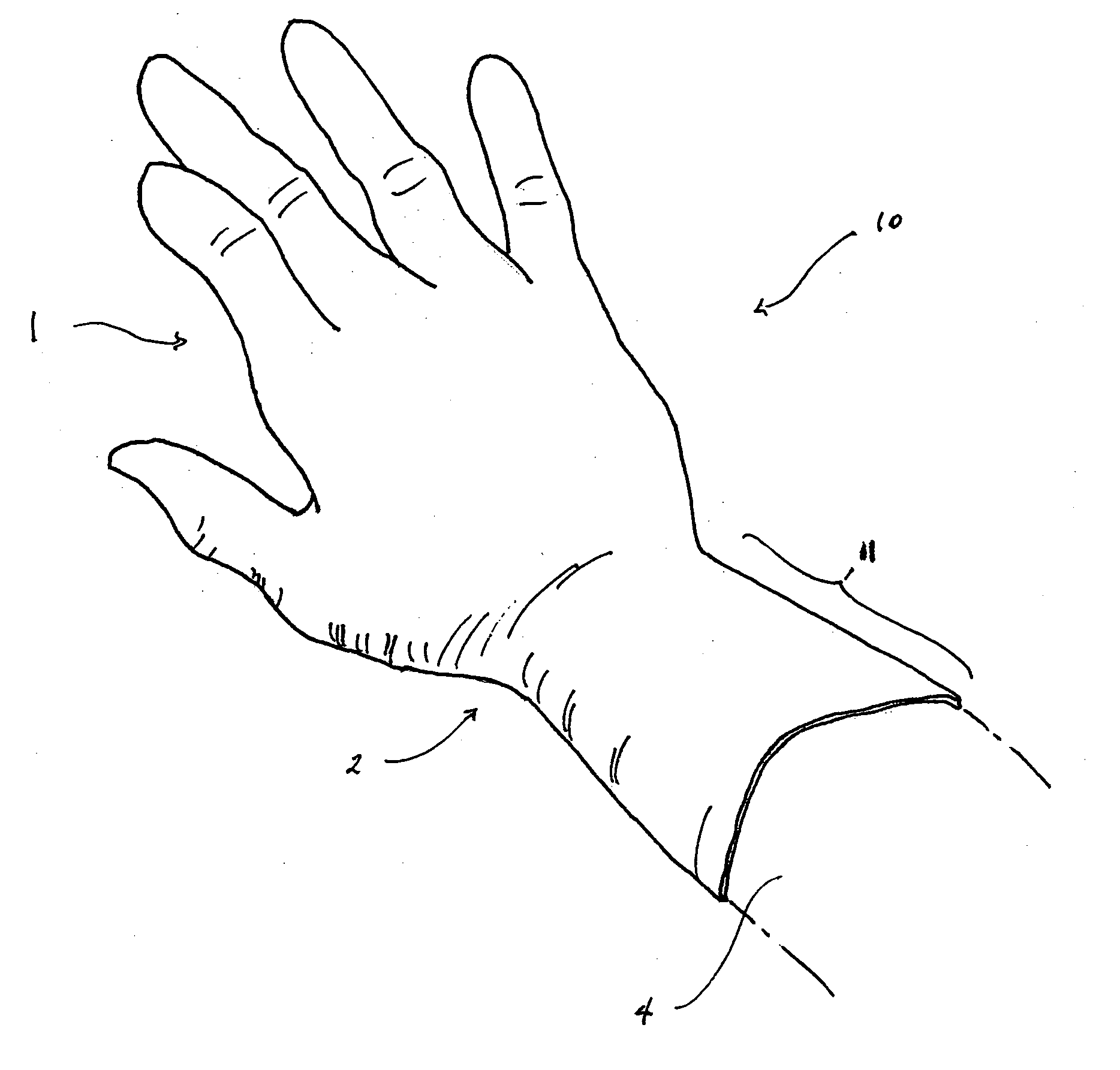

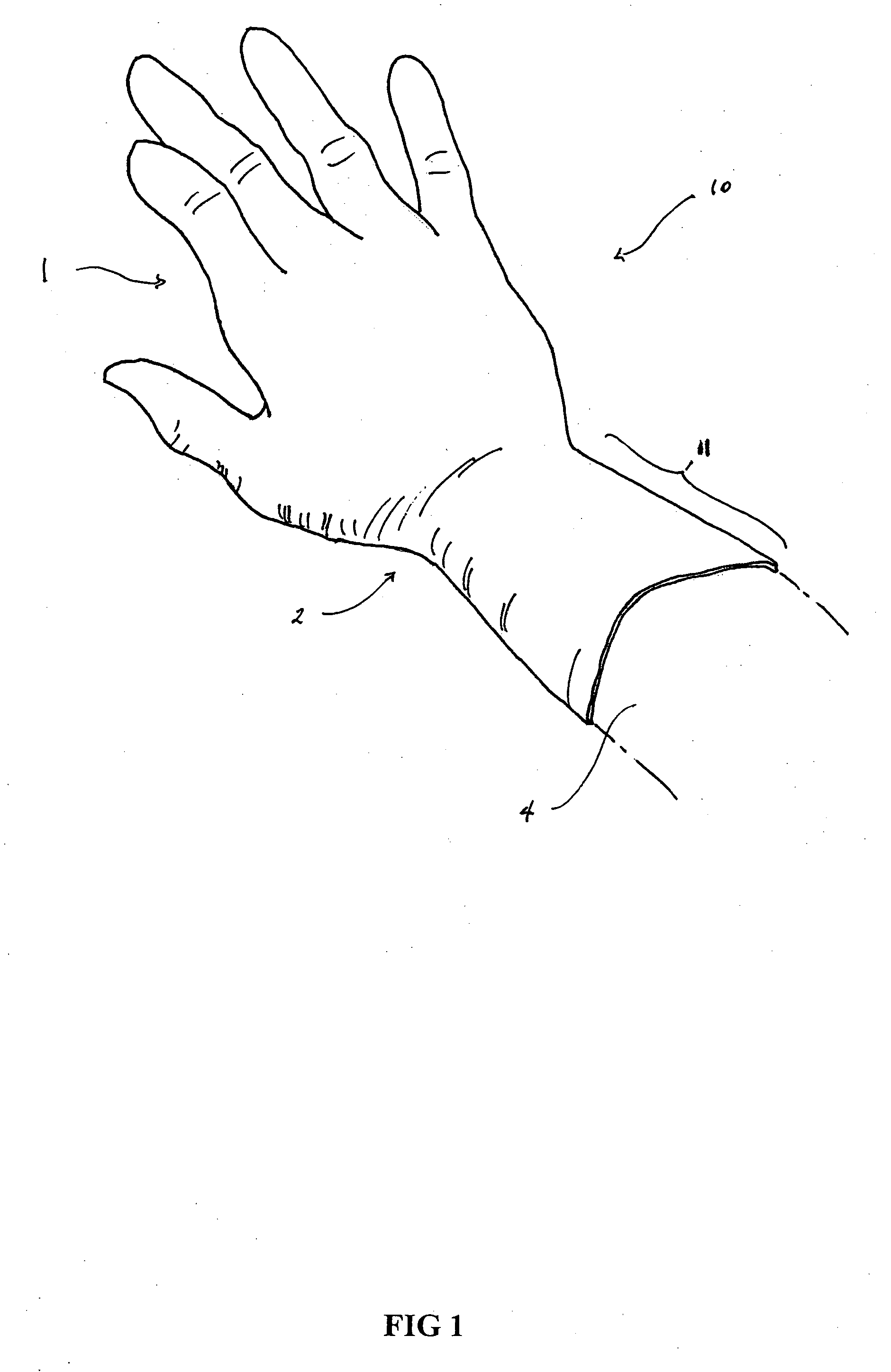

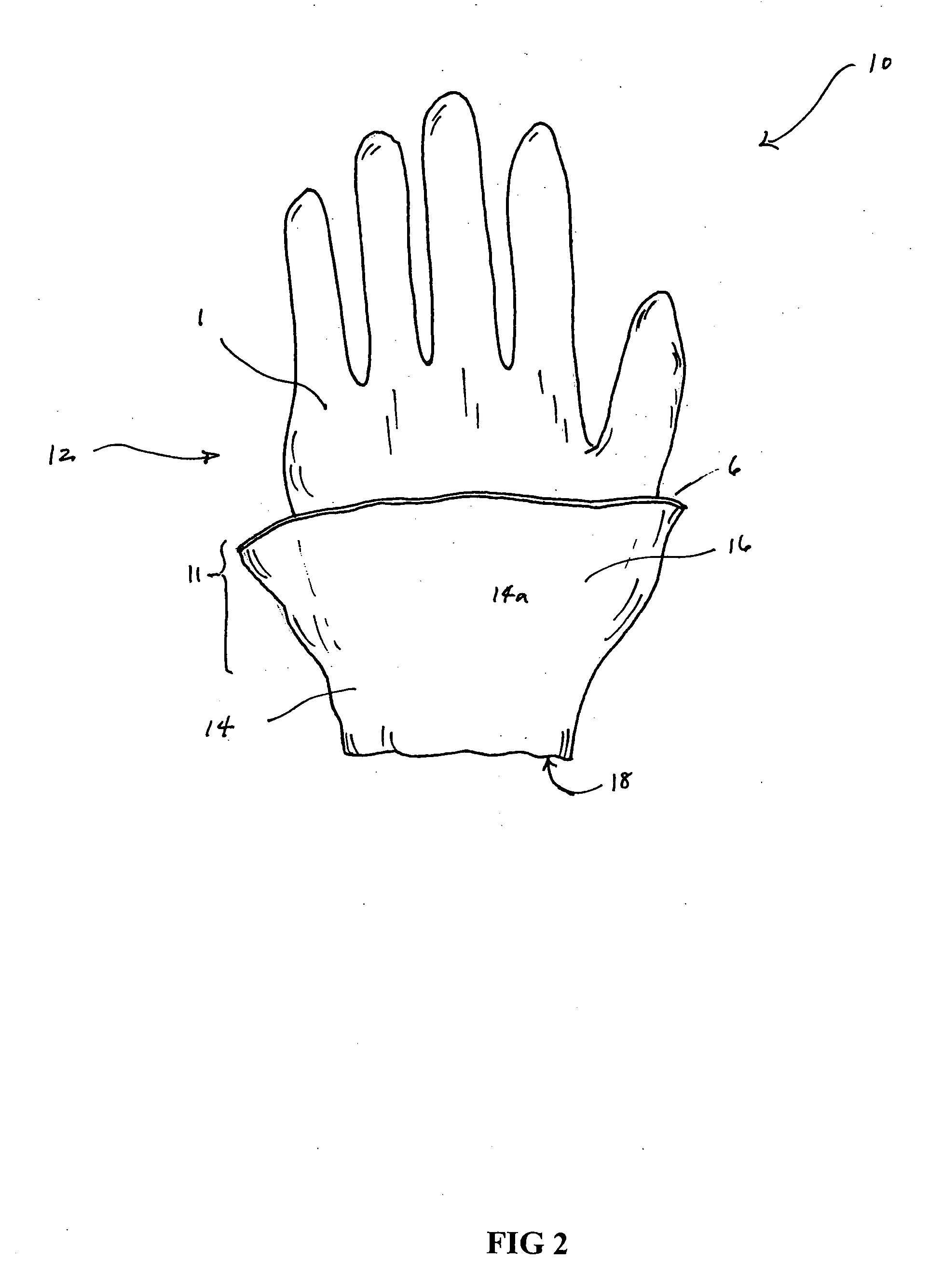

Image

Examples

example 1

[0030] According to the online process the hand-shaped former is dipped in a coagulant bath to coat the mould. A natural or synthetic rubber latex is applied by dipping into a bath and partial dried on the mould. A bead may be formed at the cuff. While the latex substrate is on the former, the glove is subject to a first water leach. An AlSO4 (e.g., Active Bond™) solution (˜1%) is applied by either spraying or dipping of the glove into an aqueous bath for about 1-3 minutes, over the entire surface of the glove, up to and including the glove cuff. AlSO4 functions as a primer that helps enhance subsequent surface modifications. A donning coat, such as a hydrogel or polyurethane layer, is applied over part of the AlSO4-coated surface. The AlSO4 on the surface of the hydrogel layer is unreacted with the hydrogel. Typically, an area with a width of about 1 or 2 inches to up to about 5 or 7 inches (˜2.5-13 or 16 cm), down from the end of the glove cuff or bead, if present, is left uncoate...

example 2

[0034] In an alternate tumbling process, a surgical glove made from an elastic latex can be manufactured by dipping the former into a coagulant solution. As with the previously described steps, a former is coated with a layer of either natural rubber or synthetic latex and allowed to partial dry. A bead may be formed at the end of the latex substrate. A first water leach is applied, followed with a coating of AlSO4 over the entire exposed surface of the latex substrate on the former. A partial hydrogel coating is applied only over the hand and wrist regions of the mould, dried and cured. A band or region of latex is left uncoated. This band can have a width of about 1-6 inches, preferably about 1-2 inches (2.5-5 cm), from the terminal edge or bead, if present. The glove is subjected to a second water leach and dried. The entire glove is then dipped into a CaCO3 slurry, and dried. Afterwards, the glove is stripped from the mould and inverted. The subsequent process steps and chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com