Method for operating an internal combustion engine

a technology of internal combustion engine and operating method, which is applied in the direction of machines/engines, electrical control, output power, etc., can solve the problems of deterioration in the overall efficiency of the internal combustion engine, and achieve the effects of reducing the overall efficiency of the internal combustion engine, and reducing the opening duration of the gas exchange valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

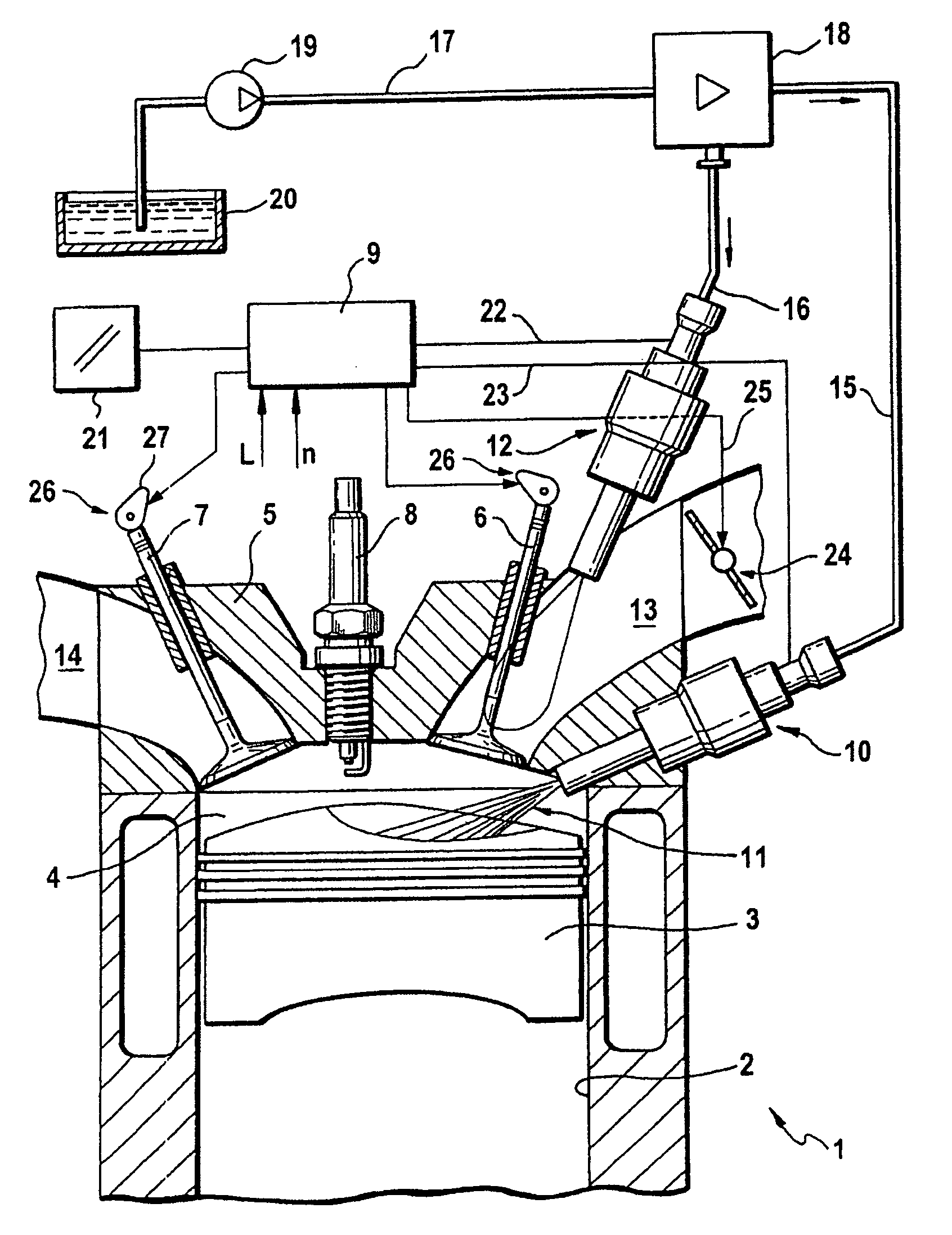

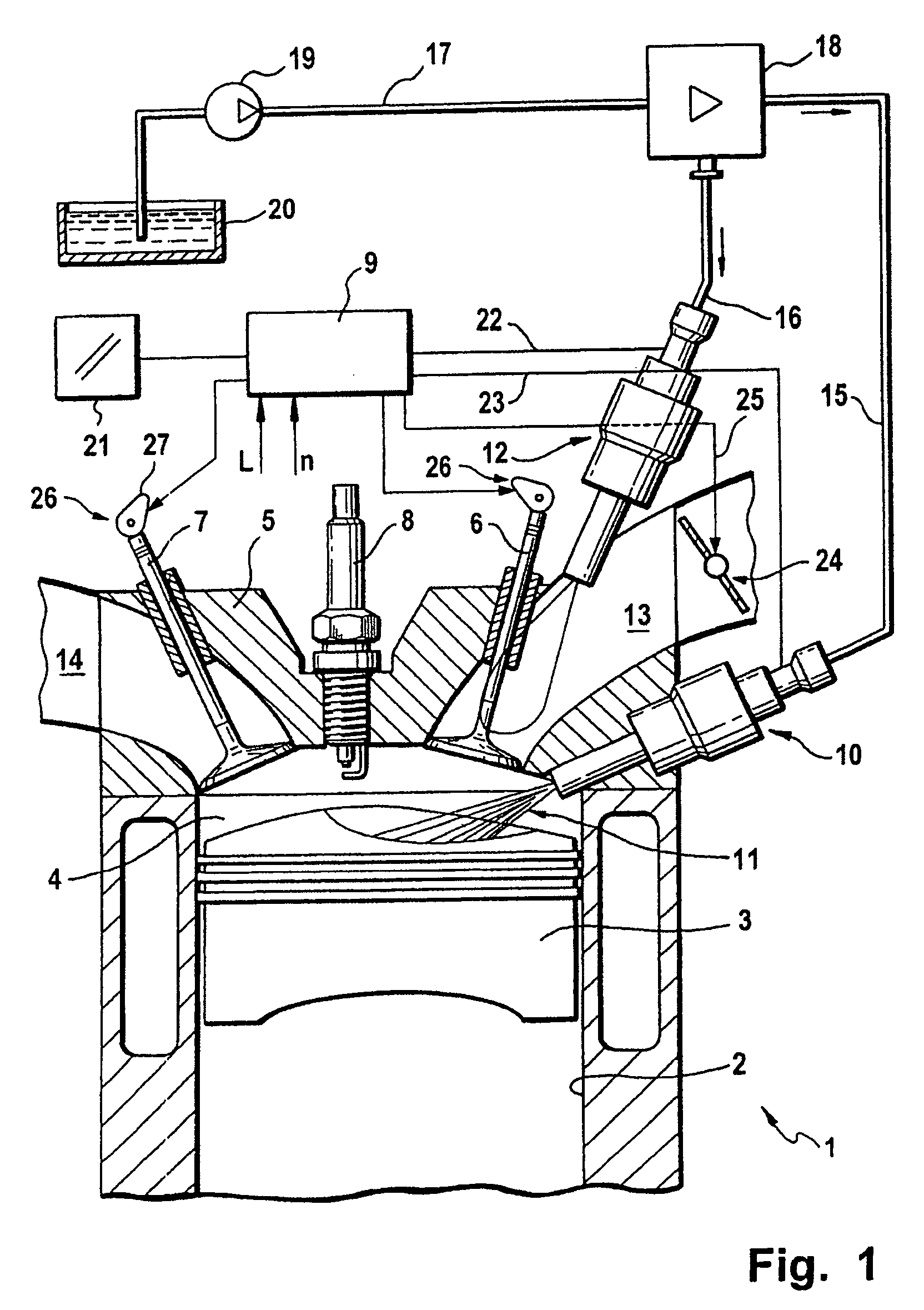

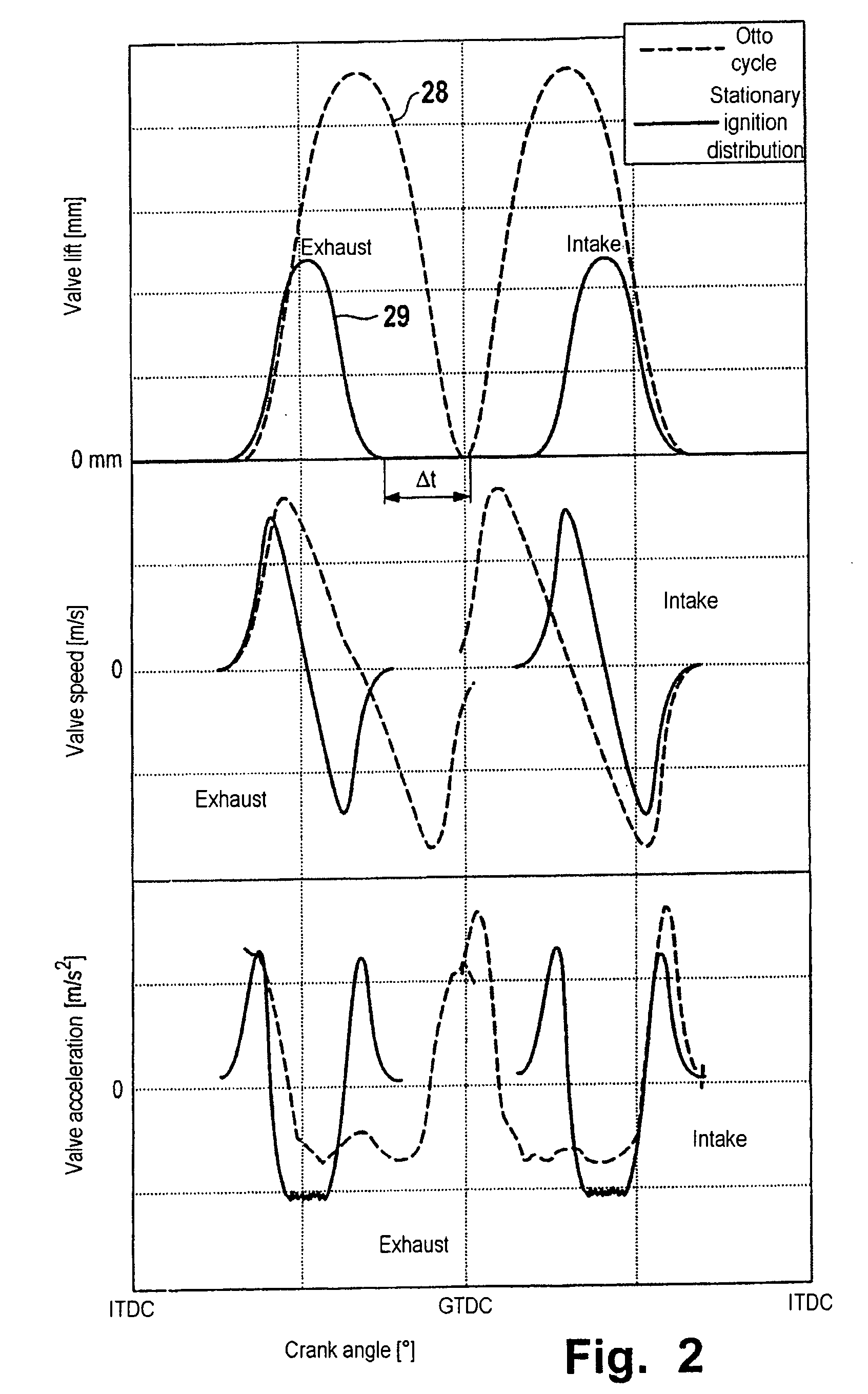

[0014]FIG. 1 shows a reciprocating-piston internal combustion engine 1, in each of whose cylinders 2 there is arranged a longitudinally movable reciprocating piston 3 which delimits a combustion chamber 4 that is closed off by a cylinder head 5 attached to the cylinder 2. A mix of fuel and combustion air is formed in the combustion chamber 4 and burnt in order to drive the reciprocating piston 3. At least one intake port 13 and an exhaust port 14 are formed in the cylinder head 5. Oxygen-rich fresh gas is supplied through the intake port 13, and the combustion exhaust gases are discharged from the combustion chamber through the exhaust port 14. Gas exchange valves 6, 7, which are driven by a valve operating mechanism 26 and, depending on the nature of the four-stroke method, cyclically open the intake port 13 and with regard to the exhaust valve 7 open the exhaust port 14, are provided for the purpose of controlling the charge exchange. To meter in the fuel required for combustion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com