Biofuel conversion process

a biofuel and conversion process technology, applied in the field of biofuel conversion process, can solve problems such as inefficiency of processes, and achieve the effect of enhancing energy conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

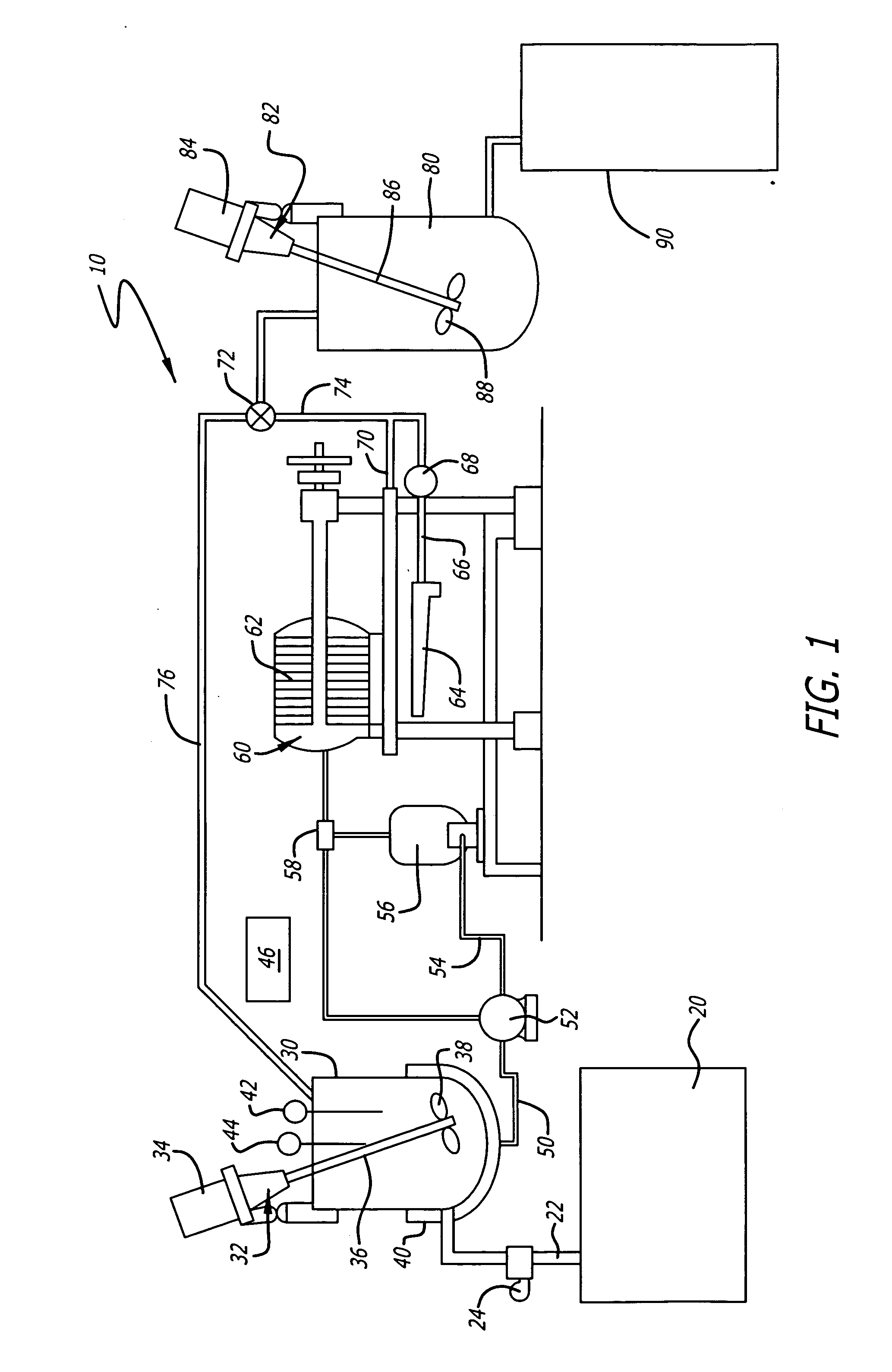

[0015]FIG. 1 schematically depicts a basic biofuel conversion apparatus 10 according to a first aspect of the present invention. The apparatus 10 includes an oil tank 20 that is either a large storage tank or plurality of storage drums. Oil from tank 20 is routed via pipe 22 and pump 24 to a catalyst tank 30. The catalyst tank 30 includes a mixing apparatus 32, for example a motor 34, shaft 36 and impeller 38. The lower section of the catalyst tank 30 includes a heating assembly 40, for example a steam heat exchange system. The catalyst tank 30 also includes a temperature sensor 42 and may include a level sensor 44. The temperature sensor 42 is connected to a controller 46 that controls the pump 24 and the timing of the process as well as the temperature control for the heating assembly 40.

[0016] Upon completion of a reaction period in the catalyst tank 30, the mixture is delivered via a pipe 50 to pump 52. The output of pump 52 is directed to a pipe 54. Pipe 54 delivers the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com