Methods for processing, optimization, calibration and display of measured dielectrometry signals using property estimation grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

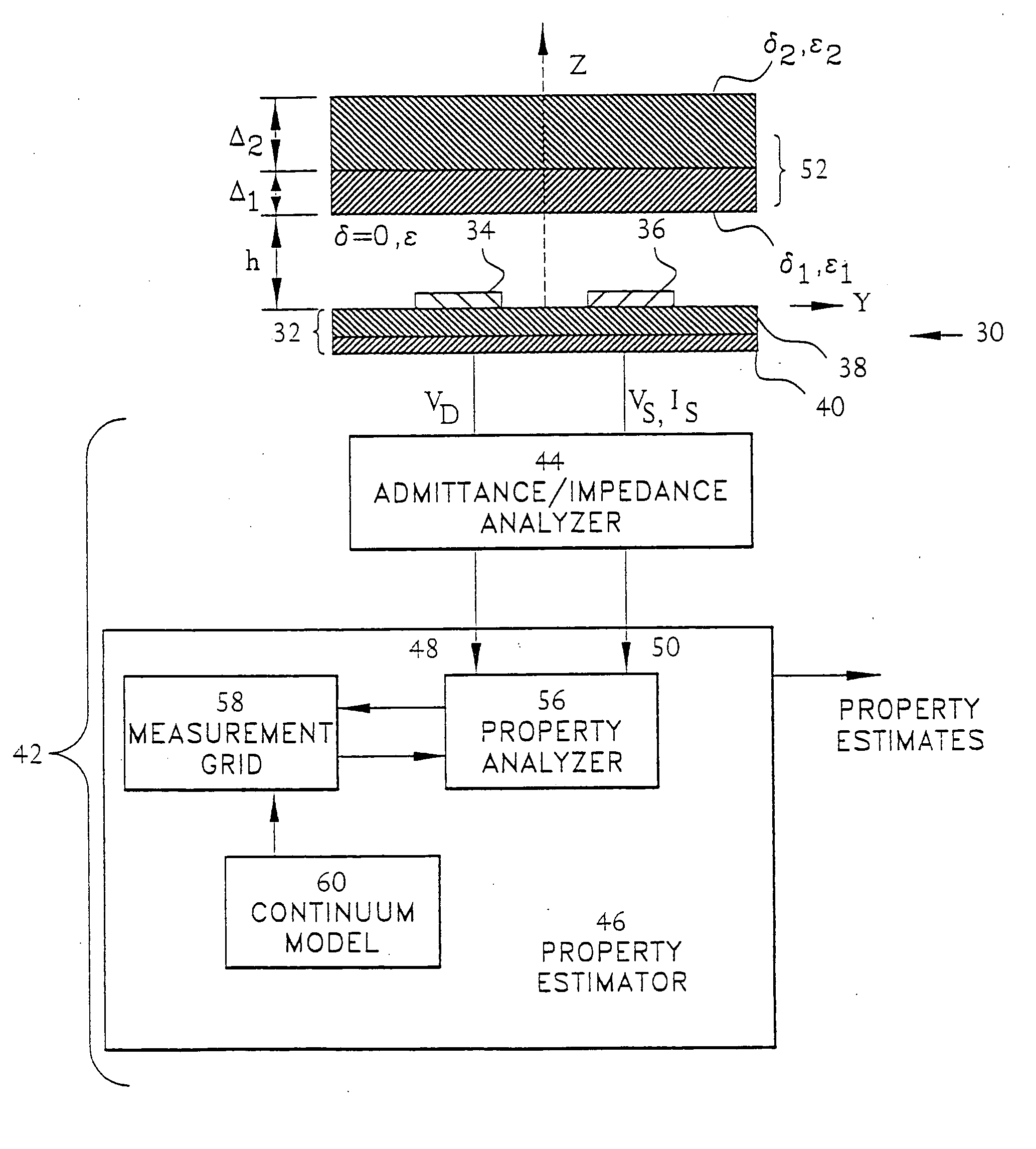

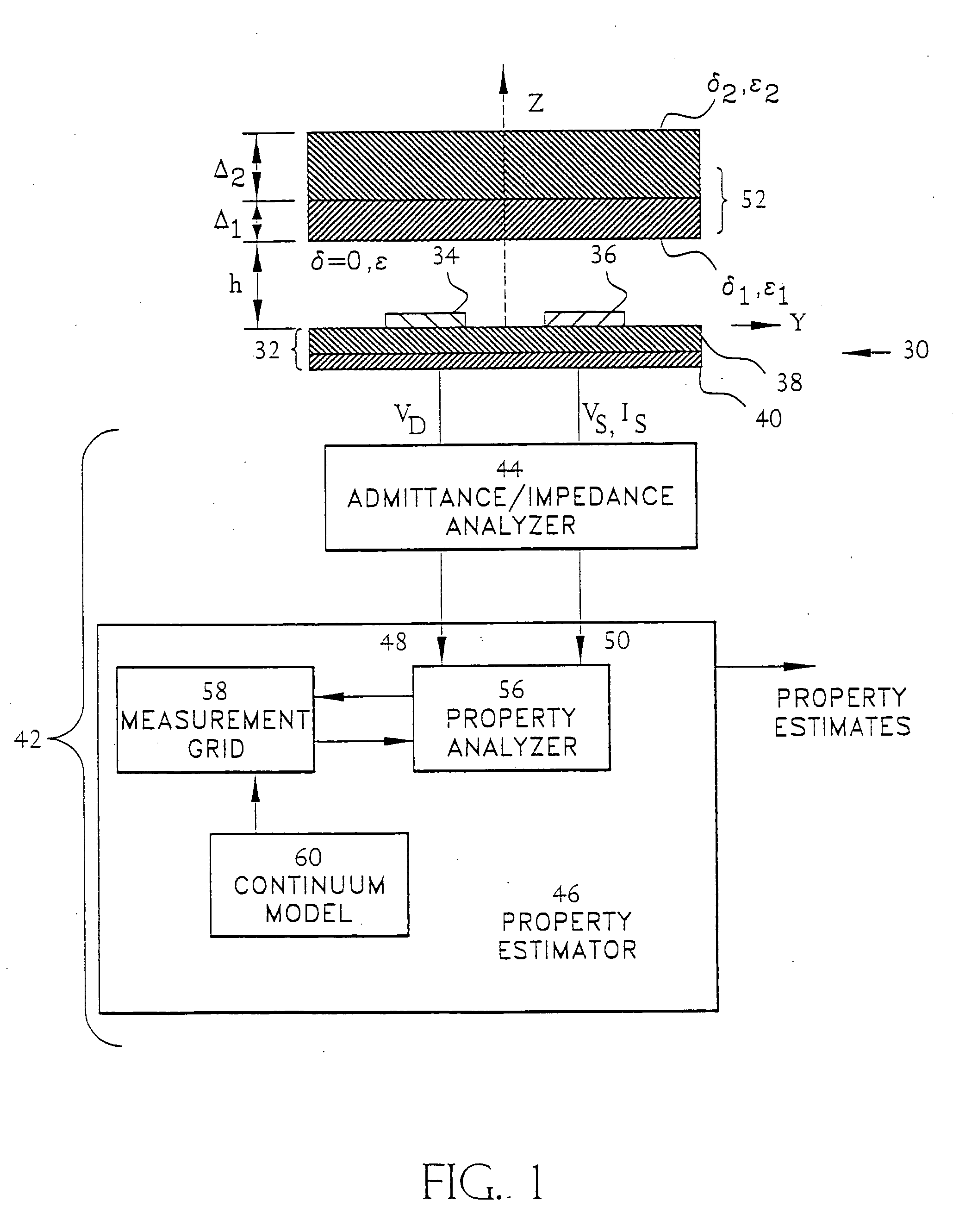

[0040] Methods, techniques, and devices are disclosed for measurements of electrical, physical, and dimensional properties of a material under test as well as geometric and kinematic properties of the measurement arrangement. These measurements are made with both contact and non-contact of the material under test by a sensor. For contact measurements, the sensor may be embedded in material under test (MUT).

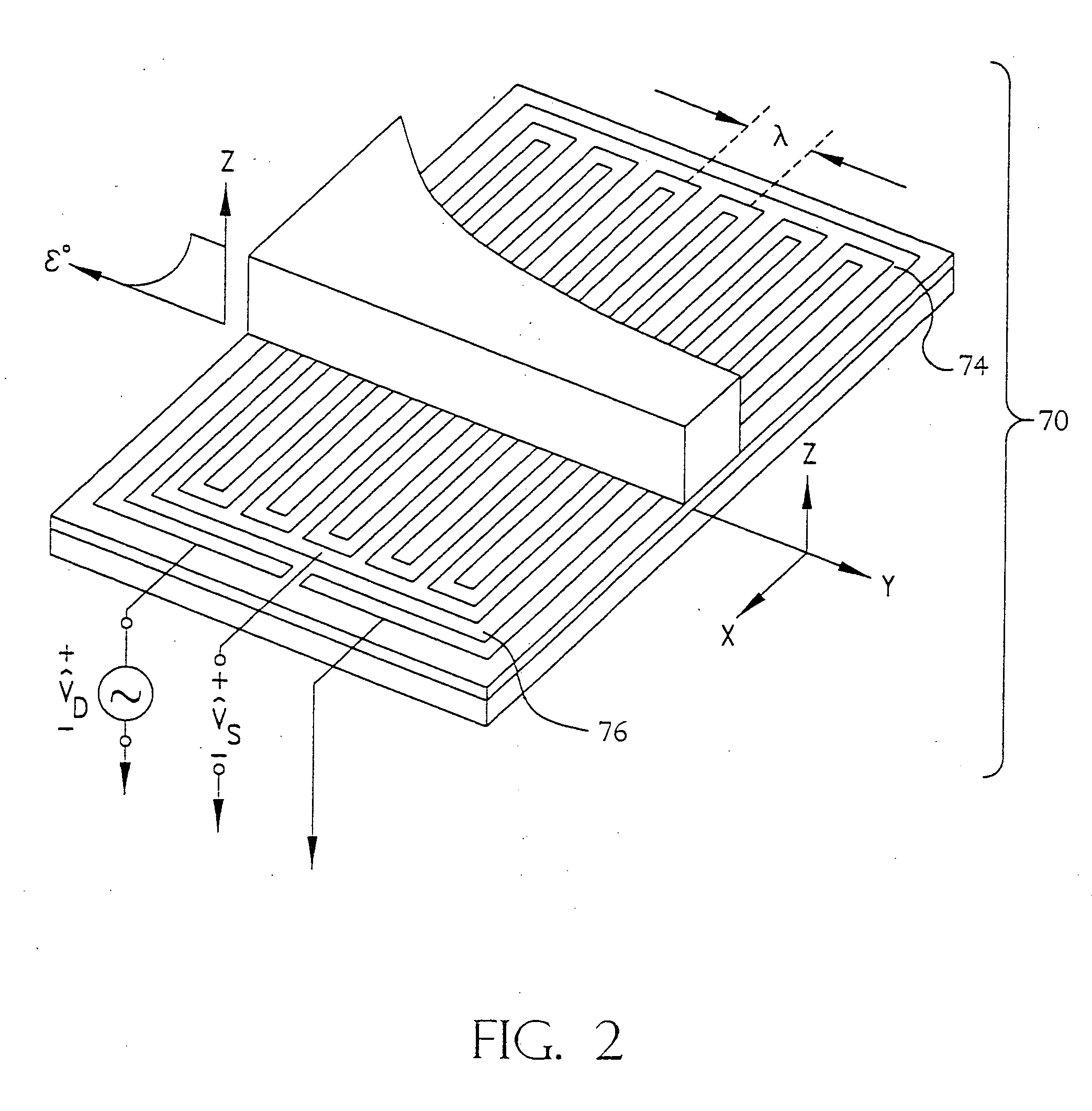

[0041] A measurement apparatus 30 is illustrated in FIG. 1. The measurement apparatus 30 includes an electromagnetic element 32 comprised of voltage driven electrode 34, voltage or current sensing electrode 36, a dielectric substrate 38 that is preferably highly electrically insulating, and a highly conducting back plane 40.

[0042] The driven electrode 34 has an imposed electrical excitation, typically either a voltage or current that can be either periodically varying in time such as sinusoidally or square wave varying with time at frequency f measured in Hertz for frequency dom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com