Dressing tool, dressing device, dressing method, processing device and semiconductor device producing method

a dressing device and dressing surface technology, applied in the direction of grinding/polishing apparatus, grinding machine components, grinding/polishing machines, etc., can solve the problems of uneven deterioration of the construction of the dressing apparatus, imbalance of the contact surface pressure between the dressing surface, etc., to ensure the flatness of the polishing surface of the polishing pad, and high degree of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Preferred working configurations of the present invention will be described below with reference to the figures. However, the descriptions of these working configurations do not limit the scope of the present invention.

[First Working Configuration]

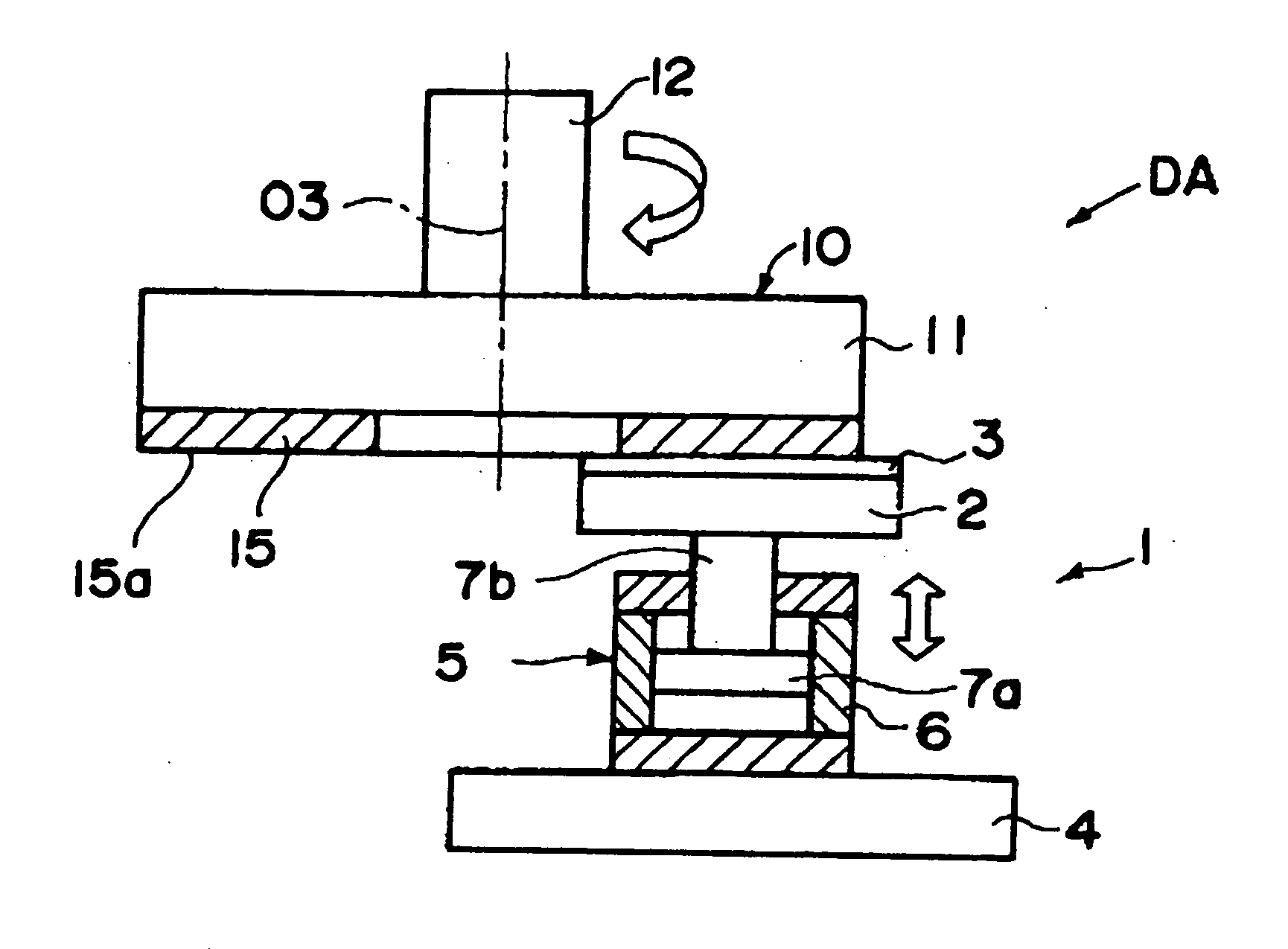

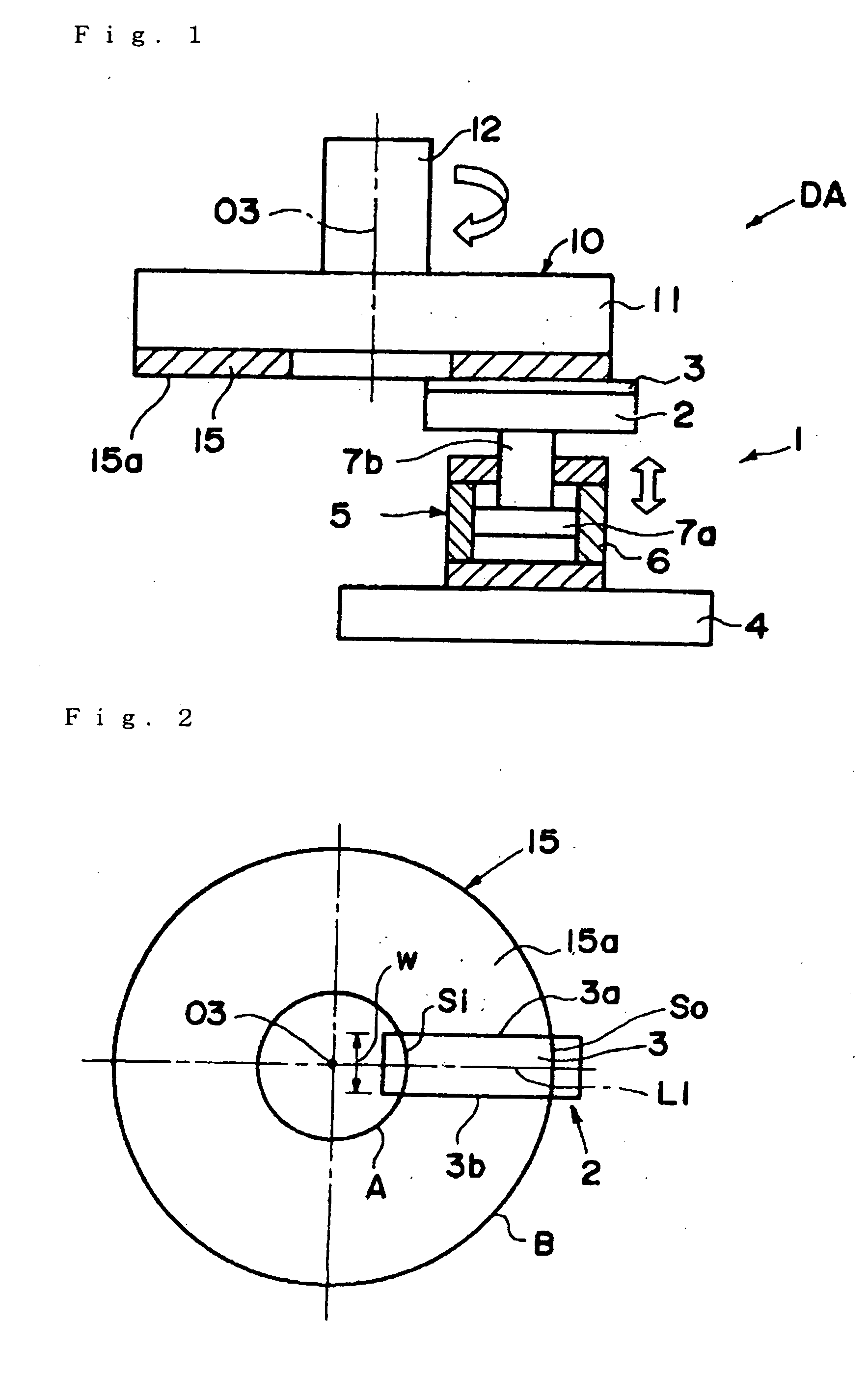

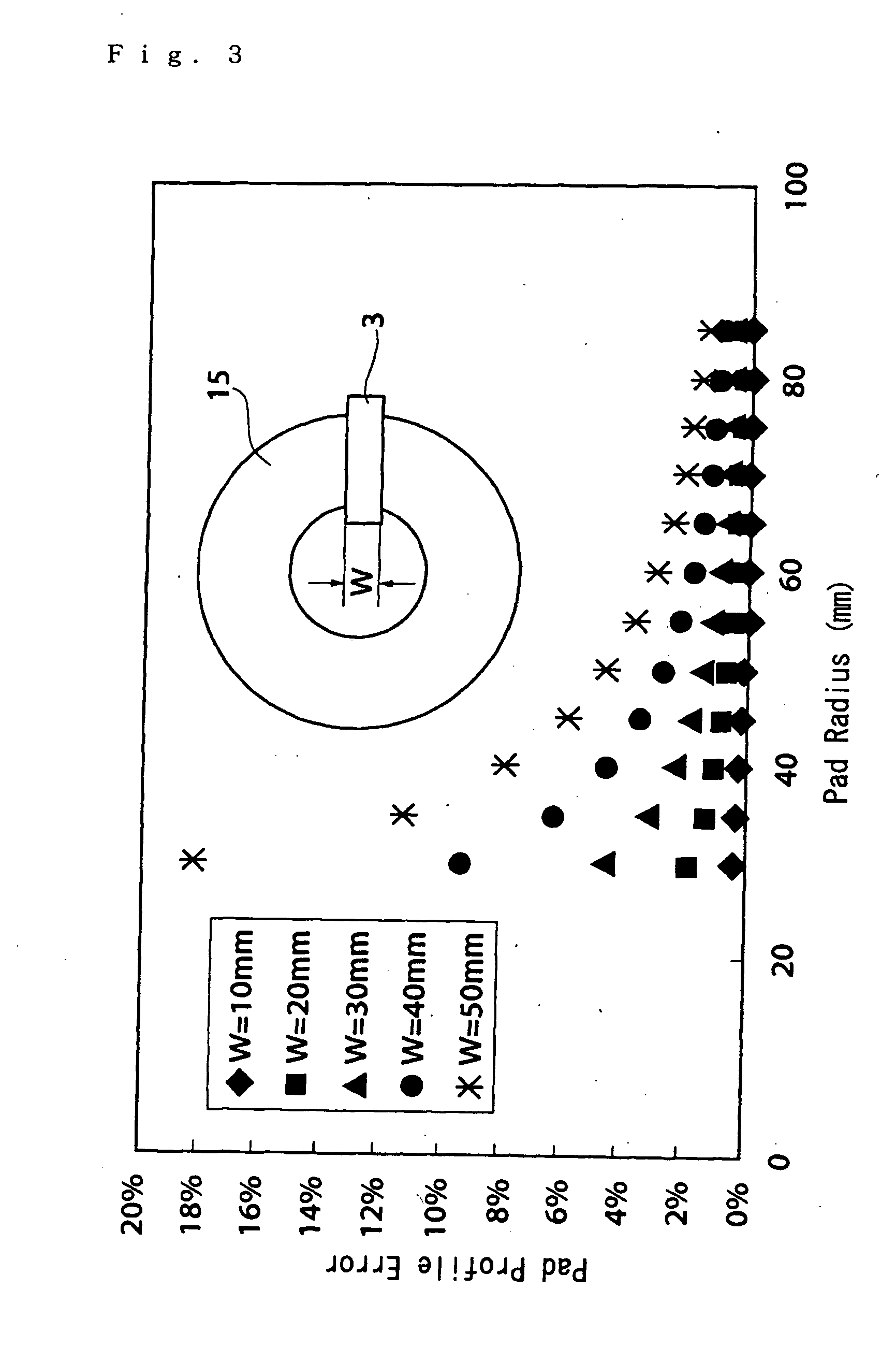

[0065] A dressing apparatus DA for a polishing pad constructed using the dressing tool 2 of the present invention is shown in FIG. 1. This dressing apparatus DA is an apparatus which dresses a pad surface (polishing surface) 15a of a polishing pad 15 used in a CMP apparatus, and is constructed from a pad holding mechanism 10 which holds the polishing pad 15 by vacuum chucking, etc., and causes this polishing pad 15 to rotate, and a dressing tool holding mechanism 1 which has a dressing tool 2 that dresses the pad surface 15a of the polishing pad 15 that is held and caused to rotate by the above-mentioned pad holding mechanism 10. The pad holding mechanism 10 is constructed from a pad holding head 11 which holds the polishing pad 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| DA | aaaaa | aaaaa |

| external diameter | aaaaa | aaaaa |

| external diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap